Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | SPS5710-2-LF |

| Manufacturer | Honeywell |

| Product category | Safety PLC input module |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Number of safety inputs | 8 safety-rated digital inputs |

| Input voltage | 24V DC (18-30V DC) |

| Input current | 7mA per channel (at 24V DC) |

| Response time | ≤10ms (including diagnostics) |

| Communication interface | Safety backplane, optional Ethernet/IP |

| Diagnostic coverage | ≥99% |

| Power supply | 24V DC (redundant capable) |

| Power consumption | 3.5W typical, 5W maximum |

| Operating temperature | -20°C to 60°C (-4°F to 140°F) |

| Storage temperature | -40°C to 85°C (-40°F to 185°F) |

| Dimensions (W×H×D) | 100mm×160mm×200mm |

| Weight | Approximately 550g |

| Protection rating | IP20 (when mounted in safety cabinet) |

| Certifications | TÜV, ATEX, IECEx, UL 1998 |

| Mounting | DIN rail (35mm) in safety-rated enclosures |

Honeywell SPS5710-2-LF

Product introduction

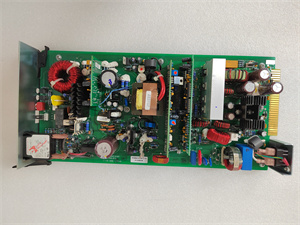

The Honeywell SPS5710-2-LF is a high-reliability safety PLC input module engineered for safety instrumented systems (SIS) in industrial settings. As a key component of Honeywell’s Safety Manager system, this module specializes in monitoring critical safety inputs, enabling rapid detection and response to hazardous conditions where human safety and asset protection are critical.

Honeywell SPS5710-2-LF is equipped with 8 individually isolated safety digital inputs, designed to interface with emergency stops, safety interlocks, and trip sensors. Its SIL 3 certification confirms it meets the highest safety standards, making it ideal for applications such as chemical reactor protection, refinery emergency shutdown systems, and pharmaceutical process safety. When paired with complementary safety output modules, the SPS5710-2-LF forms a complete safety loop, from hazard detection to controlled shutdown.

Core advantages and technical highlights

SIL 3 safety certification

The SPS5710-2-LF is certified to SIL 3 (IEC 61508), ensuring it delivers exceptional fault tolerance and diagnostic coverage (≥99%). This level of integrity is essential in high-risk environments—for example, in a chemical plant, it reliably detects overpressure conditions in reaction vessels, where a single failure could lead to catastrophic releases. Continuous self-testing runs in the background without interrupting operation, providing constant validation of the module’s readiness.

Fast response and input isolation

With a response time of ≤10ms (including diagnostics), the SPS5710-2-LF ensures immediate detection of safety events. When an emergency stop button is activated on a production line, the module processes the signal within milliseconds, triggering a rapid shutdown sequence. Each input channel features 2.5kV galvanic isolation, preventing cross-channel interference and ground loops that could compromise signal integrity in noisy industrial environments.

Redundant design flexibility

The SPS5710-2-LF supports redundant power supplies and integrates seamlessly into 2-out-of-2 (2oo2) or 2-out-of-3 (2oo3) safety architectures, eliminating single points of failure. In offshore oil platforms, this redundancy ensures the module continues operating during power fluctuations or partial system faults, maintaining safety coverage in harsh and unpredictable conditions.

System compatibility

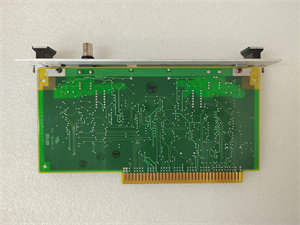

Designed for plug-and-play integration with Honeywell’s Safety Manager controllers, the SPS5710-2-LF communicates via a dedicated safety backplane, ensuring secure data transmission. It works with standard safety protocols, enabling integration with emergency shutdown valves and alarms, creating a unified safety ecosystem that can be monitored and configured centrally.

Honeywell SPS5710-2-LF

Typical application scenarios

Chemical processing safety systems

In chemical manufacturing facilities, the SPS5710-2-LF monitors gas detectors, pressure relief valves, and emergency stop buttons. For example, in a chlorine processing plant, input channel 1 connects to a toxic gas detector—if chlorine levels exceed safe limits, the SPS5710-2-LF detects the signal within 10ms and triggers a shutdown command, isolating the affected area. Its ATEX certification allows safe operation in Zone 2 hazardous areas, where flammable or toxic vapors may be present.

Oil refinery emergency shutdown

In crude oil distillation units, the SPS5710-2-LF receives inputs from high-temperature sensors and fire detectors. If a furnace overheats (detected via input channel 4), the module signals the safety controller to close isolation valves and activate fire suppression systems. Its ability to operate in temperatures up to 60°C ensures reliability in the hot environment of refinery control rooms.

Pharmaceutical cleanroom safety

In biopharmaceutical production, the SPS5710-2-LF monitors cleanroom door interlocks and pressure differential sensors. If a door is opened during sterile drug manufacturing (detected via input channel 2), the module immediately pauses the batch process and alerts operators, preventing contamination. Its low electromagnetic emissions ensure it doesn’t interfere with sensitive laboratory equipment.

Related model recommendations

- Honeywell SPS5720-2-LF: Safety output module that pairs with the SPS5710-2-LFto execute shutdown commands, providing 8 safety-rated outputs.

- Honeywell SPS5700-CPU: Safety controller that coordinates multiple SPS5710-2-LFmodules, executing safety logic and managing system-wide shutdowns.

- Honeywell SPS5710-2-LF-R: Redundant version of the SPS5710-2-LFwith pre-configured failover, designed for 2oo2 safety architectures.

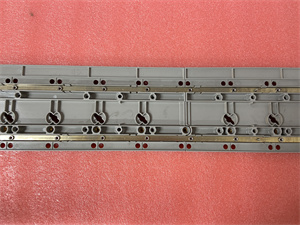

- Honeywell F860-CA: Terminal plate optimized for secure wiring termination of safety inputs to the SPS5710-2-LF, ensuring proper grounding.

- Honeywell SPS5730-COMM: Communication module that adds Ethernet/IP capability to the SPS5710-2-LF, enabling remote safety monitoring.

- Honeywell TC-OAH061: Analog output module used in parallel non-safety loops alongside the SPS5710-2-LFin integrated process systems.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the SPS5710-2-LF, ensure the mounting cabinet meets hazardous area ratings (if applicable) and provides protection from dust and moisture. Mount the module on a 35mm DIN rail using M3 screws (torque 0.5-0.7Nm), with at least 30mm clearance for cooling. Connect to a redundant 24V DC power supply using 16-20AWG twisted-pair cables, with 1A fuses on each power line. Use shielded cables for field wiring, terminated at a safety-rated terminal block (e.g., F860-CA), with shields grounded at both ends to prevent noise. Verify all connected devices (e.g., E-stops) meet SIL 3 compatibility requirements.

Maintenance suggestions

Inspect the SPS5710-2-LF quarterly for loose connections or physical damage, tightening terminals to 0.6Nm as needed. Annually test all input channels with a calibrated signal generator to verify accurate detection of both normal and fault conditions. Review diagnostic logs monthly to identify intermittent issues, which may indicate wiring problems or failing input devices. When replacing the module, use only factory-certified units and perform a full safety loop test before returning to service. Store spare SPS5710-2-LF modules in anti-static packaging in a temperature-controlled environment (-20°C to 30°C).

Service and guarantee commitment

Honeywell provides a 5-year warranty for the SPS5710-2-LF, covering defects in materials and workmanship under normal operating conditions. Our safety-certified technical support team offers 24/7 assistance for configuration, SIL verification, and system integration.

Factory repair services for the SPS5710-2-LF include recertification to SIL 3 standards, with a 7-business-day turnaround. For critical applications, we offer 48-hour emergency replacements in major industrial regions to minimize safety system downtime. Honeywell also provides specialized training on SPS5710-2-LF maintenance and safety lifecycle management, ensuring compliance with IEC 61511 and optimal long-term performance.