Description

Detailed parameter table

| Parameter name | Parameter value |

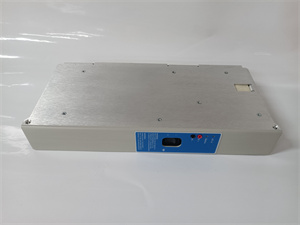

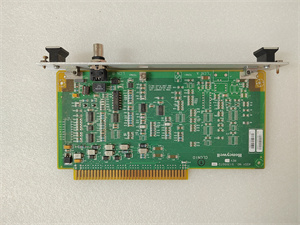

| Product model | TC-OAH061 |

| Manufacturer | Honeywell |

| Product category | Analog output module |

| Number of channels | 6 independent analog outputs |

| Output signal types | 4-20mA DC, 0-10V DC (configurable per channel) |

| Output range | 4-20mA (sink/source), 0-10V (sourcing) |

| Accuracy | ±0.1% of full scale (at 25°C) |

| Resolution | 16-bit |

| Update rate | 100ms per channel |

| Load capacity | 4-20mA: max 750Ω; 0-10V: min 1kΩ |

| Power supply | 24V DC (20-28V DC) |

| Power consumption | 5W typical, 7W maximum |

| Operating temperature | 0°C to 60°C (32°F to 140°F) |

| Storage temperature | -40°C to 85°C (-40°F to 185°F) |

| Dimensions (W×H×D) | 120mm×80mm×150mm |

| Weight | Approximately 380g |

| Protection rating | IP20 (when mounted in cabinet) |

| Communication | Backplane interface (compatible with Experion PKS) |

| Certifications | CE, UL 508, IEC 61131-2 |

| Mounting | DIN rail (35mm) or panel mount via adapter |

honeywell TC-OAH061

Product introduction

The Honeywell TC-OAH061 is a high-precision analog output module designed for integration into industrial control systems, particularly Honeywell’s Experion PKS and compatible DCS environments. As a critical interface between control modules like the TK-CCR014 and field actuators, this module converts digital control signals into standardized analog outputs, enabling precise control of valves, variable speed drives, and other process equipment.

Honeywell TC-OAH061 features 6 independent channels, each configurable for either 4-20mA current or 0-10V voltage signals, providing flexibility for diverse industrial applications. Its 16-bit resolution and ±0.1% accuracy ensure tight control over process variables, making it suitable for applications ranging from chemical dosing in water treatment to flow control in refineries. When paired with terminal plates like the F860-CA for secure wiring, the TC-OAH061 forms a reliable link in the control loop, translating digital commands into precise physical actions.

Core advantages and technical highlights

Channel flexibility and isolation

Each of the TC-OAH061’s 6 channels can be individually configured for 4-20mA or 0-10V output, eliminating the need for separate modules for different signal types. This flexibility is particularly valuable in mixed applications—for example, controlling a 4-20mA valve positioner and a 0-10V variable frequency drive (VFD) from the same module. Additionally, each channel features 2.5kV galvanic isolation from the backplane and other channels, preventing ground loops and signal interference that could degrade control accuracy in noisy industrial environments.

High accuracy and stability

With 16-bit resolution and ±0.1% full-scale accuracy, the TC-OAH061 delivers precise control signals even for small adjustments. For instance, in a pharmaceutical batch reactor, it can modulate a dosing pump’s speed with increments as small as 0.004mA (in 4-20mA mode), ensuring exact chemical proportions. The module’s low drift (≤0.01%/°C) maintains accuracy across temperature variations, critical in unconditioned control cabinets where ambient temperatures can fluctuate by 30°C or more.

Diagnostic capabilities

The TC-OAH061 incorporates advanced diagnostics to monitor channel health, including open-loop detection, overcurrent protection, and signal drift alerts. These diagnostics are communicated to the control system via the backplane, enabling proactive maintenance. For example, if a wire connected to channel 3 becomes disconnected (detected as an open loop), the module flags the issue instantly—allowing technicians to use the F860-CA terminal plate to quickly locate and repair the fault before it affects process control.

Seamless system integration

Designed for plug-and-play compatibility with Honeywell’s Experion PKS, the TC-OAH061 integrates smoothly with control modules like the TK-CCR014, enabling centralized configuration and monitoring. Its backplane communication ensures fast update rates (100ms per channel), keeping control loops responsive even in dynamic processes. The module also supports hot swapping, allowing replacement without powering down the entire system—a critical feature for maintaining uptime in continuous processes like pulp and paper manufacturing.

honeywell TC-OAH061

Typical application scenarios

Chemical processing control loops

In a specialty chemical plant producing adhesives, the TC-OAH061 controls multiple dosing valves and mixers via 4-20mA signals. Channel 1 regulates the flow of resin (4-20mA to a control valve), while channel 2 adjusts the catalyst pump speed (0-10V to a VFD). The module receives setpoints from the TK-CCR014 control module, which processes feedback from flow meters. If a valve becomes stuck, the TC-OAH061’s open-loop detection alerts operators, who use the F860-CA terminal plate to isolate the wiring and resolve the issue—minimizing batch disruption.

Water treatment plant automation

In a municipal wastewater treatment facility, the TC-OAH061 manages aeration blowers, chemical dosing pumps, and sludge thickeners. Channels 3-4 control 4-20mA actuators regulating air flow in biological reactors, maintaining optimal dissolved oxygen levels. Channels 5-6 use 0-10V signals to adjust polymer dosing pumps, ensuring efficient sludge dewatering. The module’s diagnostic features detect clogged pump lines (via current spikes), triggering alarms before chemical shortages affect treatment quality. Its ability to operate in warm control cabinets (up to 60°C) ensures reliability in unconditioned facilities.

Food and beverage production

In a beverage bottling plant, the TC-OAH061 controls filling machines and temperature regulators. Channel 1 sends 4-20mA signals to adjust filling valve positions, ensuring precise volume control for each bottle. Channel 2 uses 0-10V to modulate a heater in the pasteurization unit, maintaining exact temperatures for food safety. The module’s high accuracy prevents overfilling (reducing waste) and ensures consistent pasteurization, while its galvanic isolation protects sensitive control signals from noise generated by bottling line motors.

Related model recommendations

- Honeywell TC-OAH081: 8-channel variant of the TC-OAH061, offering additional output points for larger systems requiring more analog control signals.

- Honeywell TC-IAH061: Analog input module that complements the TC-OAH061, receiving sensor data to form complete control loops with the TK-CCR014.

- Honeywell TK-CCR014: Control module that sends digital setpoints to the TC-OAH061, which converts them to analog outputs for field devices.

- Honeywell F860-CA: Terminal plate used to terminate field wiring from actuators connected to the TC-OAH061, ensuring secure connections.

- Honeywell TC-ODX161: Digital output module that pairs with the TC-OAH061, providing on/off control for contactors and solenoids alongside analog control.

- Honeywell TC-PRS01: Power supply unit optimized for the TC-OAH061, delivering stable 24V DC to ensure output accuracy.

- Honeywell 8C-IP0102: Industrial Ethernet switch that facilitates communication between the control system and the TC-OAH061in distributed setups.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the TC-OAH061, verify compatibility with the host control system (e.g., Experion PKS) and ensure firmware versions are up to date. Mount the module on a 35mm DIN rail or panel using the optional adapter, ensuring at least 20mm clearance on all sides for ventilation. Connect the 24V DC power supply using 18-22AWG wires, with a dedicated 1A fuse in the circuit. For field wiring, use shielded twisted-pair cables terminated at a F860-CA terminal plate, grounding the shield at the module end only. Configure channel types (4-20mA/0-10V) via the system configuration software before powering on.

Maintenance suggestions

Inspect the TC-OAH061 quarterly for loose connections or dust accumulation—use compressed air (max 50psi) to clean ventilation slots. Verify output accuracy annually using a precision calibrator, checking that 4mA corresponds to 0% and 20mA (or 10V) to 100% of range. If drift exceeds ±0.2% of full scale, perform a channel calibration via the system software. Monitor diagnostic data for open loops or overcurrent events, which indicate field wiring issues or faulty actuators. When replacing the module, use the hot-swap feature to minimize downtime, ensuring the replacement unit has the same firmware version as the original. Store spare modules in anti-static packaging in a dry environment (0-50°C).

Service and guarantee commitment

Honeywell provides a 3-year warranty for the TC-OAH061, covering defects in materials and workmanship under normal operating conditions. Our technical support team offers 24/7 assistance for configuration, troubleshooting, and integration with components like the TK-CCR014 and F860-CA.

Factory-certified repair services ensure that any faulty modules are restored to original specifications, with turnaround times under 5 business days. For critical applications, we offer expedited replacement with next-business-day delivery in major regions. Honeywell also provides training on TC-OAH061 calibration, diagnostics, and system integration, ensuring users maximize its performance in industrial control loops.