Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | F860-CA |

| Manufacturer | Honeywell |

| Product category | Industrial terminal plate |

| Number of terminals | 24 terminals (12 pairs) |

| Terminal type | Screw-clamp terminals, suitable for 0.5-2.5mm² wires |

| Rated voltage | 600V AC/DC |

| Rated current | 16A per terminal |

| Material | PA66 housing (flame-retardant UL94 V0), copper alloy contacts |

| Mounting type | DIN rail (35mm) or panel mount |

| Dimensions (W×H×D) | 100mm×65mm×40mm |

| Weight | Approximately 180g |

| Protection rating | IP20 |

| Certifications | CE, UL 1059, IEC 60947-7-1 |

| Color | Gray housing with white terminal markers |

| Marking | Pre-printed terminal numbers, compatible with custom labels |

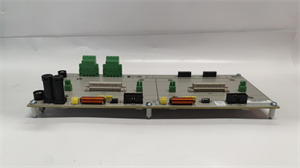

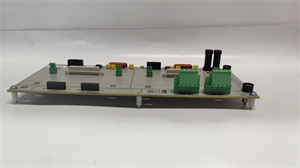

HONEYWELL TERMINAL PLATE F860-CA

Product introduction

The Honeywell F860-CA is a robust industrial terminal plate designed to provide secure and organized electrical connections in automation systems, particularly when paired with control modules like the TK-CCR014. As a critical interface between field devices (sensors, actuators) and control systems, this terminal plate simplifies wiring management, reduces installation time, and enhances maintenance efficiency in industrial environments.

Honeywell F860-CA features 24 terminals arranged in 12 pairs, offering a standardized connection point for signal and power wires. Its flame-retardant housing and high current/voltage ratings make it suitable for use in control cabinets across various industries, including manufacturing, energy, and water treatment. Whether used to terminate sensor cables in a pharmaceutical plant or connect actuator wiring in a refinery, the F860-CA ensures reliable electrical continuity and protects connections from mechanical stress and environmental factors.

Core advantages and technical highlights

Secure wire termination

The F860-CA utilizes screw-clamp terminals that provide a tight, vibration-resistant connection for 0.5-2.5mm² wires. The copper alloy contacts ensure low contact resistance (≤5mΩ), minimizing signal loss—critical for analog signals from pressure transmitters or temperature sensors connected to modules like the TK-CCR014. In high-vibration environments such as pump stations, this secure termination prevents wire loosening, a common cause of intermittent control system failures.

Flame-retardant and durable construction

Constructed with PA66 plastic (UL94 V0 flame rating), the F860-CA resists ignition and slows flame spread in case of electrical faults—enhancing safety in control cabinets housing components like the TK-CCR014. The material also withstands temperatures from -40°C to 105°C, ensuring dimensional stability in extreme industrial environments. Unlike lower-grade terminal plates, it resists chemical exposure to oils, greases, and cleaning agents commonly found in manufacturing facilities.

Flexible mounting and labeling

Compatible with both 35mm DIN rails and panel mounting, the F860-CA adapts to various cabinet layouts. Its pre-printed terminal numbers (1-24) simplify wiring documentation, while blank label spaces allow custom marking for specific signals (e.g., “PT-100 Temp” or “Valve Position”). This organization reduces troubleshooting time—technicians can quickly identify connections during maintenance on systems integrating the TK-CCR014, minimizing downtime.

Space-efficient design

With a compact footprint (100mm×65mm×40mm), the F860-CA maximizes usable space in crowded control cabinets. Its stacked terminal arrangement allows high-density wiring without sacrificing access—each terminal remains easy to tighten or disconnect using a standard screwdriver. In modular control systems with multiple TK-CCR014 modules, this space efficiency enables neat, organized wiring harnesses that simplify system expansion.

HONEYWELL TERMINAL PLATE F860-CA

Typical application scenarios

Control cabinet wiring for DCS systems

In a chemical plant’s Distributed Control System (DCS) cabinet, the F860-CA serves as the termination point for field wiring connecting to the TK-CCR014 control module. It terminates 4-20mA signals from pressure sensors, digital inputs from flow switches, and relay outputs to valve actuators. The terminal plate’s organized layout allows technicians to trace wires easily during troubleshooting—for example, quickly isolating a faulty temperature sensor by checking continuity at terminals 5-6. Its flame-retardant housing provides an extra layer of safety alongside the TK-CCR014’s protective features in hazardous chemical processing areas.

Machine automation panels

In automotive assembly line control panels, the F860-CA connects proximity sensors, solenoid valves, and motor starters to PLCs and I/O modules. Its vibration-resistant terminals ensure reliable connections in environments where machinery vibrations could loosen standard terminals. For example, in a robotic welding cell, the F860-CA terminates position sensor wires, ensuring the TK-CCR014 (or compatible PLC) receives accurate position data to maintain weld precision. The terminal plate’s labeling capability also helps during preventive maintenance, allowing quick identification of wires needing inspection.

Energy sector control systems

In a natural gas processing plant’s compressor control skid, the F860-CA terminates wiring for pressure transmitters, temperature gauges, and emergency shutdown signals. Its 600V rating safely handles both low-voltage control signals and 240V AC power wiring for small motors, eliminating the need for separate terminal blocks. When paired with the TK-CCR014 module, it ensures clean signal transmission for critical control loops regulating compressor speed and pressure, contributing to safe and efficient operation.

Related model recommendations

- Honeywell F860-CB: A 36-terminal variant of the F860-CA, offering more connection points for larger systems with multiple TK-CCR014

- Honeywell F860-DA: Double-deck terminal plate with 48 terminals, designed for high-density wiring applications where the F860-CA’s 24 terminals are insufficient.

- Honeywell TK-CCR014: Process control module that pairs with the F860-CA—the terminal plate terminates field wiring connected to the module’s I/O channels.

- Honeywell F860-TB: Terminal block with built-in surge protection, ideal for outdoor applications or areas with frequent voltage spikes, complementing the F860-CAin harsh environments.

- Honeywell F860-MK: Marking kit for the F860-CA, including pre-printed labels for common signals (e.g., “AI-1”, “DO-3”) to simplify system documentation.

- Honeywell F860-Cover: Protective cover for the F860-CA, increasing protection to IP40 by shielding terminals from dust and accidental contact.

- Honeywell TK-IOL016: I/O module that uses the F860-CAfor field wiring termination, working alongside the TK-CCR014 in distributed control setups.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the F860-CA, ensure the mounting surface (DIN rail or panel) is clean and free of burrs. For DIN rail mounting, use a rail cutter to trim the 35mm rail to length, ensuring the terminal plate is positioned with at least 50mm clearance from adjacent components for wiring access. Prepare wires by stripping 8-10mm of insulation, avoiding nicks in the conductor. Use a torque screwdriver set to 0.8-1.2Nm to fasten wires—over-tightening may damage terminals, while under-tightening can cause resistance buildup. When connecting to sensitive equipment like the TK-CCR014, route signal wires through separate conduits from power wires to minimize interference.

Maintenance suggestions

Inspect the F860-CA quarterly for loose terminals or corrosion—retighten any loose screws to 1.0Nm using a calibrated torque screwdriver. Clean dust from the housing with a dry cloth; avoid using water or solvents that could degrade the PA66 material. Check wire insulation for signs of overheating (brittleness or discoloration), which indicates excessive current—replace such wires and verify the load is within the 16A rating. When replacing the F860-CA, label wires before removal using the terminal numbers as a reference, ensuring correct reconnection. Store spare terminal plates in a dry environment (10-30°C) to prevent moisture-related corrosion of contacts.

Service and guarantee commitment

Honeywell provides a 5-year warranty for the F860-CA, covering defects in materials and workmanship under normal operating conditions. Our technical support team offers assistance with installation best practices and compatibility checks with other components like the TK-CCR014, ensuring optimal integration into control systems.

Replacement parts and spare units are available globally, with next-business-day delivery in major industrial regions to minimize downtime. Honeywell’s application engineers can also provide wiring diagrams and labeling guidelines specific to the F860-CA, helping customers achieve organized, maintainable control cabinet layouts. This commitment to quality and support reflects our confidence in the F860-CA’s durability and its role in reliable industrial automation systems.