Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | TK-CCR014 |

| Manufacturer | Honeywell |

| Product category | Process control module |

| Compatible systems | Experion PKS (Process Knowledge System) |

| Processing capacity | 1000 control loops, 5000 I/O points |

| CPU | 32-bit RISC processor, 800 MHz |

| Memory | 512 MB RAM, 1 GB flash storage |

| Communication interfaces | 2×Ethernet (10/100/1000 Mbps), 1×RS485 (Modbus RTU) |

| Operating system | Real-time operating system (RTOS) |

| Power supply | 24V DC (18-30V DC) |

| Power consumption | 25W typical, 35W maximum |

| Operating temperature | 0°C to 55°C (32°F to 131°F) |

| Storage temperature | -40°C to 70°C (-40°F to 158°F) |

| Dimensions (W×H×D) | 160mm×100mm×220mm |

| Weight | Approximately 1.2kg |

| Protection rating | IP20 (when mounted in cabinet) |

| Certifications | CE, UL 508, IEC 61131-2, SIL 2 compliant |

| Redundancy support | 1:1 hot standby capability |

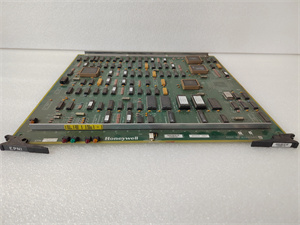

HONEYWELL TK-CCR014

Product introduction

The Honeywell TK-CCR014 is a high-performance process control module designed for integration into Honeywell’s Experion PKS (Process Knowledge System), a leading industrial automation platform. As a key component in distributed control systems (DCS), this module executes control strategies, processes real-time data from field devices, and communicates with other system components to ensure seamless operation of industrial processes.

Honeywell TK-CCR014 combines robust processing power with reliable communication capabilities, supporting up to 1000 control loops and 5000 I/O points—making it suitable for medium to large-scale industrial applications. Its real-time operating system ensures deterministic control, with response times measured in milliseconds, critical for time-sensitive processes like chemical batch reactions or power generation. Whether deployed in refineries, pharmaceutical plants, or water treatment facilities, the TK-CCR014 delivers the stability and precision required for mission-critical operations.

Core advantages and technical highlights

High processing efficiency

The TK-CCR014 features an 800 MHz 32-bit RISC processor that handles complex control algorithms—such as model predictive control (MPC) and proportional-integral-derivative (PID) loops—without performance degradation. In a large chemical plant, this processing power enables the module to manage 500+ PID loops simultaneously, each with update rates as fast as 100ms, ensuring tight control over reaction temperatures and pressures. This efficiency eliminates the need for multiple lower-capacity modules, reducing system complexity and cost.

Redundancy for uninterrupted operation

Supporting 1:1 hot standby redundancy, the TK-CCR014 ensures zero downtime in critical applications. If the primary module fails, the standby unit automatically takes over within 50ms, with no loss of control data or process continuity. In a nuclear power plant’s secondary cooling system, this redundancy is vital—preventing process disruptions that could compromise safety. The module’s self-monitoring diagnostics continuously check for faults, triggering automatic switchover before issues affect process control.

Seamless system integration

The TK-CCR014 integrates seamlessly with other Experion PKS components, including operator stations, engineering workstations, and I/O modules, via its gigabit Ethernet ports. Its support for Modbus RTU also allows communication with legacy devices like motor starters and flow meters, making it ideal for plant modernization projects. In a food and beverage facility upgrading from a legacy DCS, the module acts as a bridge, enabling new control strategies while retaining connectivity to existing sensors and actuators.

Enhanced security features

Built with industrial cybersecurity in mind, the TK-CCR014 includes features such as role-based access control, encrypted communication, and firmware integrity checks. These measures prevent unauthorized modification of control parameters—a critical protection in industries like oil and gas, where malicious tampering could have catastrophic consequences. The module also supports Honeywell’s Secure Media Manager, ensuring that configuration updates are validated and free from malware before installation.

HONEYWELL TK-CCR014

Typical application scenarios

Refining and petrochemicals

In oil refineries, the Honeywell TK-CCR014 controls distillation columns, managing temperature, pressure, and flow rates of hydrocarbons. Its ability to execute advanced control algorithms optimizes separation efficiency, increasing yields of high-value products like gasoline and jet fuel by up to 2%. The module’s redundancy feature is particularly valuable here—any unplanned shutdown of a distillation unit can cost millions in lost production, making uninterrupted operation a top priority. Integration with Experion PKS allows operators to monitor and adjust controls via a centralized HMI, with the TK-CCR014 ensuring real-time execution of their commands.

Pharmaceutical manufacturing

Within pharmaceutical plants, the TK-CCR014 oversees batch processing of active pharmaceutical ingredients (APIs), where precise control of temperature, pH, and agitation speed is critical for product quality. The module’s deterministic performance ensures that PID loops regulating reactor conditions maintain setpoints within ±0.1°C, meeting strict regulatory requirements. Its support for electronic batch records (EBR) allows seamless data logging of control actions, simplifying compliance with FDA and EMA guidelines. In a vaccine production facility, this level of control and documentation ensures consistent batch quality, a necessity for public health.

Water and wastewater treatment

Municipal wastewater treatment plants use the TK-CCR014 to automate biological treatment processes, controlling aeration, sludge recirculation, and chemical dosing. The module processes data from dissolved oxygen sensors and flow meters, adjusting blower speeds and valve positions to optimize treatment efficiency while minimizing energy use. For example, during periods of low influent flow, the TK-CCR014 reduces aeration rates, cutting energy consumption by 15-20% compared to fixed-speed systems. Its Modbus connectivity also allows integration with SCADA systems, enabling remote monitoring by plant operators.

Related model recommendations

- Honeywell TK-CCR032: Higher-capacity variant of the TK-CCR014, supporting up to 2000 control loops—ideal for large-scale refineries or integrated chemical complexes.

- Honeywell TK-IOL016: I/O module that pairs with the TK-CCR014, providing 16 analog inputs (4-20mA) for connecting field sensors.

- Honeywell TK-CCR014-R: Redundant version of the TK-CCR014with pre-configured standby hardware, simplifying redundancy setup in critical applications.

- Honeywell EXPERION PKS C300: Controller that integrates with the TK-CCR014in expanded systems, offering enhanced visualization and data analytics.

- Honeywell TK-COM02: Communication module that adds Profibus DP support to the TK-CCR014, enabling connectivity with Siemens and other Profibus-compatible devices.

- Honeywell UDA2182-CC1-CC2-NN-N-0000-EE-000: Process transmitter that sends pressure and flow data to the TK-CCR014for control decisions in closed-loop systems.

- Honeywell TK-HMI01: Operator interface terminal that displays real-time data processed by the TK-CCR014, allowing manual control adjustments when needed.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell TK-CCR014, ensure the mounting rack in the control cabinet is level and securely fastened, capable of supporting 1.2kg. Use ESD-safe tools to handle the module, and wear a grounded wrist strap to prevent electrostatic damage to internal components. Connect Ethernet cables (Cat6 or higher) to the gigabit ports, ensuring proper termination to avoid signal loss. For redundant configurations, verify that both primary and standby TK-CCR014 modules have identical firmware versions before powering on. Provide a dedicated 24V DC power supply with a 2A fuse, and route power wiring separately from signal cables to minimize electromagnetic interference.

Maintenance suggestions

Inspect the TK-CCR014 monthly for loose connections or dust accumulation—use compressed air (max 40psi) to clean ventilation slots if necessary. Monitor CPU and memory usage via Experion PKS diagnostics; values consistently exceeding 70% indicate potential overload and may require rebalancing control loops across multiple modules. Perform firmware updates annually during scheduled shutdowns, using Honeywell’s Experion Engineering Tools to ensure compatibility with other system components. In redundant setups, test failover functionality quarterly by manually triggering a switchover and verifying uninterrupted process control. Store spare modules in anti-static packaging in a climate-controlled environment (15-30°C) to preserve performance.

Service and guarantee commitment

Honeywell backs the TK-CCR014 with a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. Our global technical support team provides 24/7 assistance for system integration, troubleshooting, and optimization, with response times within 4 hours for critical issues in process-critical applications.

Factory-certified repair services ensure that any faulty TK-CCR014 modules are restored to original specifications using genuine components. For customers operating in major industrial regions, we offer next-business-day delivery of replacement units to minimize downtime. Honeywell also provides comprehensive training programs for the TK-CCR014, including hands-on workshops on control strategy implementation and redundancy configuration, ensuring users maximize the module’s capabilities within their Experion PKS environment.