Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

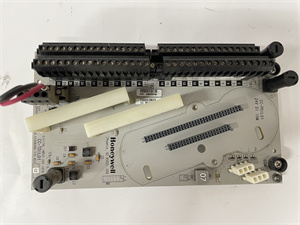

| Product Model | Honeywell UDA2182-CC1-CC2-NN-N-0000-EE-000 |

| Manufacturer | Honeywell |

| Product Category | Universal Differential Pressure Transmitter |

| Pressure Range | 0-100 psi (0-6.9 bar) standard (custom ranges available) |

| Accuracy | ±0.075% of span |

| Output Signal | 4-20mA with HART® 7 protocol |

| Power Supply | 10.5-42V DC (loop powered) |

| Process Connection | 1/4″ NPT female (CC1/CC2 in model number) |

| Wetted Materials | 316L stainless steel, Hastelloy C, Viton® |

| Operating Temp | -40°C to +85°C (-40°F to +185°F) |

| Storage Temp | -50°C to +100°C (-58°F to +212°F) |

| Response Time | <100ms to 90% of step change |

| Stability | ±0.1% URL per year |

| Protection Rating | IP67, NEMA 4X |

| Certifications | SIL 2, ATEX, IECEx, PED, CRN |

UDA2182-CC1-CC2-NN-N-0000-EE-000

Product Introduction

The Honeywell UDA2182-CC1-CC2-NN-N-0000-EE-000 represents Honeywell’s advanced universal differential pressure transmitter, designed for critical process measurement applications across multiple industries. This high-performance transmitter combines exceptional measurement accuracy with robust construction to deliver reliable performance in demanding environments.

As part of Honeywell’s SmartLine® product family, the Honeywell UDA2182-CC1-CC2-NN-N-0000-EE-000 features state-of-the-art sensor technology with advanced diagnostics capabilities. The transmitter’s modular design allows for easy configuration and maintenance, while its comprehensive certifications make it suitable for use in hazardous areas and safety instrumented systems.

The “CC1-CC2″ in the model number indicates 1/4” NPT process connections, while the “EE” suffix specifies the enhanced performance version with 0.075% accuracy. This particular configuration is ideally suited for applications requiring precise differential pressure measurement with superior long-term stability.

Core Advantages and Technical Highlights

Advanced Sensor Technology:

The Honeywell UDA2182-CC1-CC2-NN-N-0000-EE-000 utilizes a single-crystal silicon sensor with proprietary DSP compensation algorithms, providing exceptional accuracy and stability over wide temperature ranges.

Intelligent Diagnostics:

Embedded health monitoring features include:

Process condition alerts (plugged impulse lines detection)

Sensor integrity verification

Electronics diagnostics

Predictive maintenance indicators

Universal Configuration:

Field-selectable parameters include:

Pressure range (through HART communicator)

Damping time constant

Output linear/square root selection

Measurement units (psi, bar, kPa, etc.)

Robust Construction:

All-welded 316L stainless steel sensor module with multiple isolation diaphragms provides superior overpressure protection (up to 10x URL) and resistance to water hammer effects.

Safety Compliance:

Certified for use in SIL 2 safety applications per IEC 61508, with additional ATEX and IECEx approvals for hazardous area installation.

Communication Capabilities:

HART 7 protocol enables:

Digital process variable transmission

Remote configuration

Advanced diagnostic access

Foundation Fieldbus compatibility (with appropriate interface)

UDA2182-CC1-CC2-NN-N-0000-EE-000

Typical Application Scenarios

Oil & Gas Production:

Wellhead flow measurement and choke valve control in offshore platforms, with ATEX-certified performance in Zone 1 hazardous areas.

Pharmaceutical Manufacturing:

Critical pressure drop monitoring across bioreactor filters and sterile processing systems, with hygienic process connections available.

Power Generation:

Feedwater flow measurement in combined cycle plants, withstanding high-temperature steam applications.

Chemical Processing:

Differential pressure monitoring across reactor beds and distillation columns, resistant to corrosive media.

Water Treatment:

Filter clogging detection in municipal water plants, with excellent performance in wet environments (IP67 rated).

Related Model Recommendations

Honeywell UDA2182-FB1-FB2 – Flanged process connections

Honeywell UDA2182-CC1-CC2-AA – Absolute pressure version

Honeywell UDA2182-CC1-CC2-GG – Gauge pressure version

Honeywell STT750 – Smart temperature transmitter

Honeywell SPT25 – Smart pressure transmitter

Honeywell HC900 – Process controller

Honeywell Experion® C300 – Process automation controller

Installation, Commissioning and Maintenance

Installation Guidelines:

Mount the Honeywell UDA2182-CC1-CC2-NN-N-0000-EE-000 with process connections oriented downward to prevent condensate accumulation. Use appropriate sealants on NPT threads. For liquid service, ensure impulse lines are properly filled and bled.

Commissioning:

Verify proper process connection installation

Apply power and check basic functionality

Configure range and units via HART communicator

Perform zero and span calibration

Verify digital communication with control system

Set appropriate damping values for application

Maintenance:

Annual zero calibration check

Biannual inspection of process connections

5-year diaphragm integrity test

Replacement of O-rings/seals every 3 years

Firmware updates as recommended by Honeywell

Service and Guarantee Commitment

Honeywell provides a 60-month warranty for the UDA2182-CC1-CC2-NN-N-0000-EE-000, including:

24/7 global technical support

On-site calibration services

Advanced replacement program

Repair and refurbishment options

Lifetime product support commitment