Description

Detailed parameter table

| Parameter name | Parameter value |

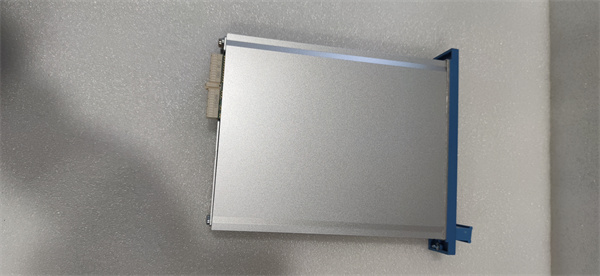

| Product model | USI-0002 |

| Manufacturer | Honeywell |

| Product category | Universal industrial interface module |

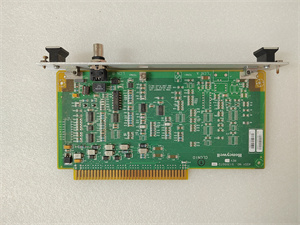

| Interface types | 2×analog inputs (4-20mA, 0-10V), 2×analog outputs (4-20mA) |

| Digital I/O | 4×digital inputs (dry contact), 2×digital outputs (relay, 5A@250V AC) |

| Communication protocols | Modbus RTU (RS485), Profibus DP (optional) |

| Power supply | 24V DC (18-30V DC) |

| Power consumption | Typical: 3W, Maximum: 5W |

| Operating temperature | -40°C to 70°C |

| Storage temperature | -50°C to 85°C |

| Humidity tolerance | 5-95% (non-condensing) |

| Dimensions (W×H×D) | 95mm×65mm×120mm |

| Weight | Approximately 220g |

| Protection rating | IP20 (module), IP65 (front panel with connector) |

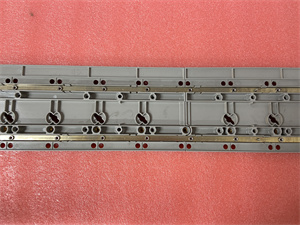

| Mounting | DIN rail (35mm) |

| Certifications | CE, UL 508, ATEX II 3G |

| Calibration | Factory-calibrated, field-calibratable via software |

HONEYWELL USI-0002

Product introduction

The Honeywell USI-0002 is a versatile universal interface module designed to bridge legacy industrial sensors/actuators with modern automation systems. As part of Honeywell’s industrial connectivity range, this compact module serves as a critical translation hub, enabling communication between devices with different signal types and protocols.

Honeywell USI-0002 combines analog and digital I/O in a single unit, eliminating the need for multiple specialized modules. Its support for Modbus RTU (with optional Profibus DP) allows seamless integration with PLCs, DCS systems, and SCADA platforms—making it ideal for retrofitting older facilities or expanding existing networks. Whether connecting pressure transducers in a chemical plant or controlling valves in a water treatment facility, the USI-0002 provides reliable signal conversion and transmission.

Core advantages and technical highlights

Multi-signal compatibility

The USI-0002 accepts both current (4-20mA) and voltage (0-10V) signals on its analog inputs, automatically detecting and scaling them without manual configuration. This flexibility allows it to connect to diverse sensors—from temperature transmitters (4-20mA) to level sensors (0-10V)—in a single installation. In food processing plants, for example, it can simultaneously monitor pH levels (4-20mA) and flow rates (0-10V) using the same module, reducing hardware costs by 30% compared to using dedicated converters.

Extreme environment durability

Built to withstand harsh industrial conditions, the USI-0002 operates reliably from -40°C to 70°C, with conformal-coated circuit boards that resist moisture, dust, and chemical exposure. This ruggedness makes it suitable for offshore platforms, where salt spray and temperature swings would degrade standard interface modules. Its ability to function in high-vibration environments (up to 10g) also ensures stability in applications like pump stations or manufacturing lines.

Simplified integration

The USI-0002 features plug-and-play configuration via Honeywell’s Universal Interface Software, which auto-detects connected devices and suggests optimal settings. Its Modbus RTU implementation supports baud rates up to 115.2kbps, ensuring fast data exchange with control systems. For legacy setups, the optional Profibus DP module allows connection to older Siemens or ABB PLCs—eliminating the need for expensive protocol converters.

Diagnostic capabilities

Equipped with advanced self-monitoring, the USI-0002 continuously checks for open circuits, signal drift, and power anomalies, flagging issues via its digital outputs or diagnostic registers. In a pharmaceutical production line, this proactive monitoring can alert operators to a failing pressure sensor before it affects batch quality—preventing costly rework. The module’s ability to log signal trends (up to 10,000 data points) also aids in troubleshooting and process optimization.

HONEYWELL USI-0002

Typical application scenarios

Chemical processing

In chemical plants, the Honeywell USI-0002 connects legacy pH and conductivity sensors to a modern DCS. Its analog inputs convert the 4-20mA signals from these sensors into Modbus data, which is then transmitted to the central control system. The module’s digital outputs trigger alarm lights if values exceed safe thresholds, while the analog outputs control dosing pumps to maintain optimal chemical balances. Its ATEX certification ensures safe operation in Zone 2 hazardous areas, a critical requirement in solvent processing units.

Water and wastewater treatment

Wastewater facilities use the USI-0002 to integrate older mechanical flow meters (0-10V output) with SCADA systems. The module converts these signals to Modbus, allowing remote monitoring of influent/effluent rates. Its digital inputs track valve positions (open/closed), while the relay outputs control pump starters—enabling automated sequence control of filtration processes. In remote pumping stations, the USI-0002’s wide temperature range ensures reliable operation through winter months without heating systems.

Food and beverage manufacturing

In beverage bottling lines, the USI-0002 monitors filling machine pressure (4-20mA) and conveyor speed (0-10V), transmitting data to a PLC for synchronization. Its digital outputs activate reject mechanisms when under/over-filling is detected, while diagnostic features alert maintenance teams to sensor calibration issues. The module’s compact size allows installation in tight spaces near filling heads, reducing cable lengths and signal interference compared to centralized I/O systems.

Related model recommendations

- Honeywell USI-0004: A higher-density variant of the USI-0002with 4 analog inputs/outputs and 8 digital I/O, suitable for larger installations requiring more points.

- Honeywell USI-0002-PB: The Profibus DP version of the USI-0002, pre-configured for Profibus networks without needing optional modules.

- Honeywell 8C-IP0102: Industrial Ethernet switch that pairs with the USI-0002to connect distributed interface modules into a unified network.

- Honeywell TC-IAH061: Analog input module that complements the USI-0002in DCS systems requiring high-channel-count analog monitoring.

- Honeywell USI-CAB05: 5-meter shielded cable set designed for the USI-0002, ensuring noise-free signal transmission in industrial environments.

- Honeywell UMC800: PLC that integrates seamlessly with the USI-0002, using its Modbus interface for centralized control of distributed sensors.

- Honeywell USI-PWR01: Redundant power supply unit for the USI-0002, providing 24V DC with automatic failover in critical applications.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell USI-0002, verify the DIN rail is securely mounted and grounded. Use a torque wrench (0.5-0.7Nm) to fasten the module, ensuring stability in vibrating environments. Connect power using 22-16AWG wires, observing polarity to prevent damage—install a 1A fuse in the positive line for protection. For signal wiring, use twisted-pair shielded cables (24-18AWG) for analog signals, grounding the shield at the module end only. Keep analog and digital wiring separate to minimize interference. Configure DIP switches for baud rate (9600 default) and address (1-247) before powering on.

Maintenance suggestions

Inspect the USI-0002 semi-annually for loose connections or corrosion on terminals—clean with a dry cloth if needed. Verify analog signal accuracy using a calibrator, checking that 4mA corresponds to 0% and 20mA to 100% of range. Use Honeywell’s interface software to perform a full diagnostic check quarterly, which verifies relay operation, input/output linearity, and communication integrity. If drift exceeds ±0.1% of full scale, perform field calibration via the software (requires standard signal generator). Store spare modules in anti-static packaging at -20°C to 60°C, avoiding exposure to chemicals or direct sunlight.

Service and guarantee commitment

Honeywell provides a 5-year warranty for the USI-0002, covering defects in materials and workmanship under normal operating conditions. Our technical support team offers 24/7 assistance for configuration, calibration, and troubleshooting, with response times within 8 hours for critical issues.

Factory-certified repairs use genuine components to restore original performance specifications. For customers in major industrial regions, we offer next-business-day delivery of replacement modules to minimize downtime. Honeywell’s training programs include hands-on sessions for USI-0002 installation and integration, ensuring users can maximize its capabilities in both new and legacy automation systems.