Description

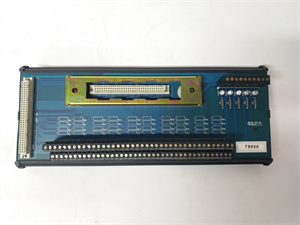

ICS Triplex T8461

-

Model Number: T8312-7 -

Manufacturer: ICS Triplex -

Product Type: Expander Interface Adapter Unit -

Input Voltage: 24V DC (nominal, 18-30V DC range) -

Power Consumption: 10W (typical) -

Operating Temperature: -20°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Dimensions: 270mm x 200mm x 50mm -

Weight: 1.5kg -

Protection Rating: IP65 (dust/water resistant) -

Certifications: CE, UL, FCC -

Supported Expander Chassis: Up to 7 units (logical IDs 2-8) -

Redundancy Architecture: Triple Modular Redundancy (TMR) with majority voting -

Hot Swap Support: Yes (enables live replacement without system shutdown) -

Communication Interface: Proprietary backplane for Triconex TMR systems

ICS Triplex T8461