Description

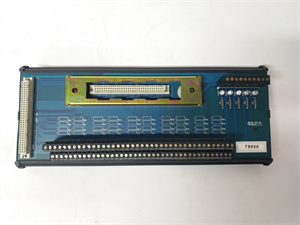

ICS Triplex T9831

-

Model Number: T8830 -

Manufacturer: ICS Triplex -

Product Type: 16-Channel Analog Input Module -

Number of Channels: 16 -

Input Type: Thermocouple (J, K, T, E) / RTD (Pt100, Pt1000) -

Input Range: Per sensor type (e.g., J-type: -200°C to +1200°C; Pt100: -200°C to +850°C) -

Accuracy: ±0.2% of reading + 0.5°C (thermocouple); ±0.1% of span (RTD) -

Signal Conditioning: Cold junction compensation, linearization, filtering -

Power Consumption: 2.8 W (from backplane) -

Safety Integrity Level: SIL 3 (when integrated into a certified SIS) -

Operating Temperature: -40°C to +70°C (-40°F to +158°F) -

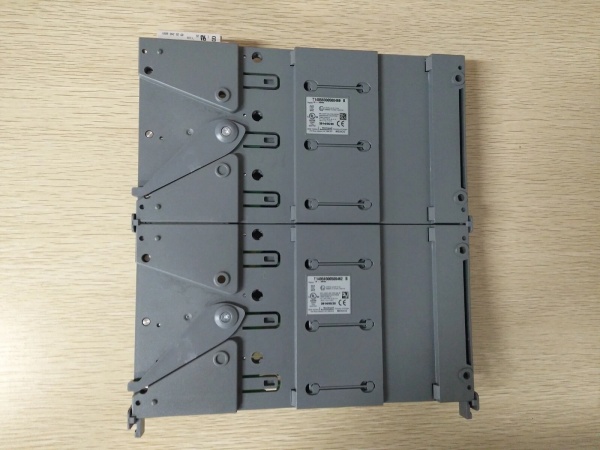

Dimensions: 31.8 mm x 128.3 mm x 119.9 mm (1.25 in x 5.05 in x 4.72 in) -

Weight: Approximately 0.38 kg (0.84 lbs) -

Certification: TÜV Rheinland certified -

Diagnostics: Open circuit, short circuit, sensor break, overrange detection

ICS Triplex T9831