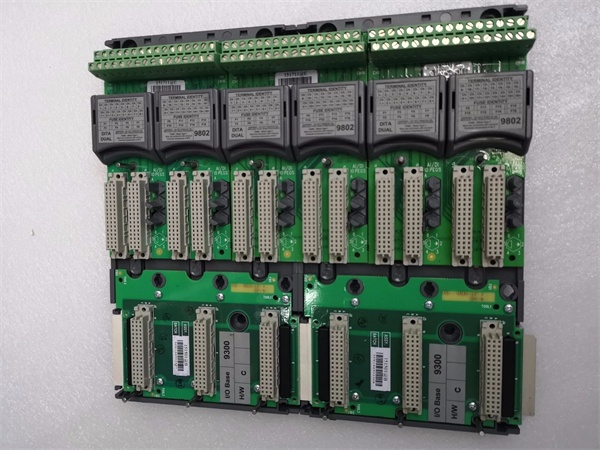

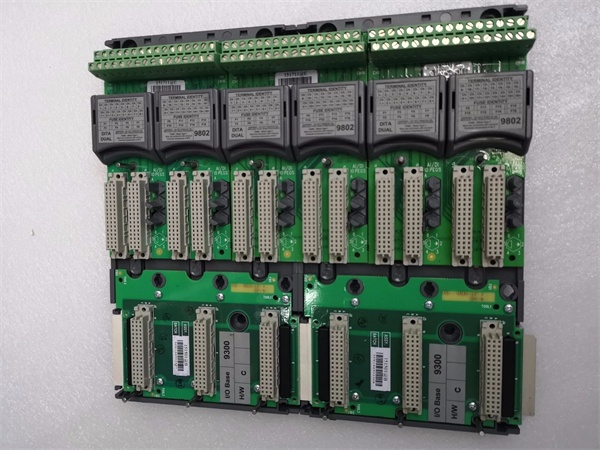

ICS Triplex T9300 | Trusted TMR I/O Backplane

Product Type: I/O Backplane

Series: Trusted TMR System

Core Function: Provides communication and power distribution for I/O modules in safety control systems

Key Specs: 24 I/O slots, 18-32V DC operation, Modbus RTU/EtherCAT/Profinet protocols

This product is already in your quote request list.