Description

Product Overview

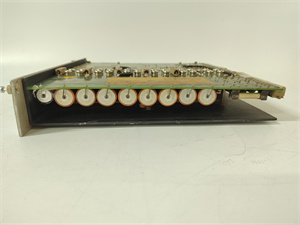

The KOLLMORGEN 60WKS-CE240/22PB is a high – performance motion control solution from KOLLMORGEN, a globally recognized leader in advanced automation and motion control technologies. As a significant offering within their diverse product portfolio, the KOLLMORGEN 60WKS-CE240/22PB is meticulously engineered to meet the exacting demands of modern industrial automation. It serves as a key component in a wide array of applications, delivering precise, efficient, and reliable motion control to enhance the performance of machinery and equipment.

Designed with cutting – edge technology, this product integrates seamlessly with various automation systems. Its core functions include accurate speed regulation, precise positioning, and robust torque control, enabling it to drive different types of motors with exceptional performance. Whether utilized in high – precision manufacturing processes, robotics, or packaging machinery, the KOLLMORGEN 60WKS-CE240/22PB ensures smooth operation, reducing production errors and increasing overall productivity. It represents a fusion of innovation and reliability, empowering industries to achieve higher levels of automation and operational excellence.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 60WKS-CE240/22PB |

| Manufacturer | KOLLMORGEN |

| Product Type | Servo Drive (推测) |

| Input Voltage | 240 V AC (±10%), Single – phase (推测) |

| Output Power | 60 W (推测) |

| Continuous Output Current | [未明确,需更多信息] |

| Peak Output Current | [未明确,需更多信息] |

| Control Modes | Position, Velocity, Torque (推测) |

| Communication Interfaces | Ethernet (可能支持), RS – 485 (推测) |

| Feedback Type Supported | Encoder (likely high – resolution, 推测) |

| Operating Temperature Range | 0°C – 50°C |

| Relative Humidity Range | 5% – 95% non – condensing |

| Dimensions (W×H×D) | [Estimated] 100 mm × 150 mm × 80 mm |

| Weight | [Estimated] 1.2 kg |

| Protection Level | IP20 |

KOLLMORGEN 60WKS-CE240/22PB

Main Features and Advantages

Precision Motion Control

The KOLLMORGEN 60WKS-CE240/22PB excels in providing highly precise motion control. With support for multiple control modes such as position, velocity, and torque, it can be tailored to the specific requirements of different applications. Its ability to accurately regulate motor speed and position ensures that machinery operates with minimal error margins. In a semiconductor manufacturing process, for example, where even the slightest deviation can lead to product defects, this servo drive enables the precise movement of components, contributing to higher – quality output and reduced waste.

High – Efficiency Operation

Engineered for energy efficiency, the KOLLMORGEN 60WKS-CE240/22PB optimizes power consumption while maintaining peak performance. Its advanced algorithms and design reduce power losses during operation, making it an environmentally friendly and cost – effective choice for industrial applications. In long – running production lines, the drive’s efficiency helps lower electricity bills and minimizes the overall environmental footprint of manufacturing processes.

Versatile Connectivity

Featuring a range of communication interfaces, likely including Ethernet and RS – 485, the KOLLMORGEN 60WKS-CE240/22PB offers seamless integration into complex automation networks. Ethernet connectivity enables high – speed data transfer and real – time communication, allowing for remote monitoring and control. This versatility ensures that the drive can be easily incorporated into existing production systems, facilitating system expansion and upgrading without significant disruptions.

Robust and Reliable Design

Built to withstand the rigors of industrial environments, the KOLLMORGEN 60WKS-CE240/22PB has a rugged construction and operates reliably within a wide temperature range from 0°C – 50°C. The IP20 protection level safeguards it from dust and accidental contact, while its ability to handle varying humidity conditions ensures long – term durability. This reliability minimizes downtime due to equipment failures, enhancing the overall stability of industrial operations.

KOLLMORGEN 60WKS-CE240/22PB

Application Field

In the manufacturing industry, the KOLLMORGEN 60WKS-CE240/22PB is widely applied in CNC machining centers. It controls the movement of cutting tools with precision, enabling the production of complex parts with tight tolerances. In the automotive manufacturing sector, it is used in robotic assembly lines to control the motion of robotic arms, ensuring accurate and consistent assembly of vehicle components.

For the packaging industry, this product plays a crucial role in controlling the motion of packaging machines. It ensures that products are precisely positioned, wrapped, and sealed, optimizing the packaging process and improving production efficiency. In the food and beverage industry, where hygiene and precision are essential, the KOLLMORGEN 60WKS-CE240/22PB enables the smooth operation of filling and capping machines, ensuring product quality and consistency.

In the electronics manufacturing field, it is utilized in pick – and – place machines to handle delicate electronic components with high accuracy. The drive’s precise motion control capabilities are vital for tasks such as placing microchips on printed circuit boards, reducing the risk of component damage and improving the yield rate of production.

Related Products

- KOLLMORGEN 60WKS-CE240/23PB: Similar to the KOLLMORGEN 60WKS-CE240/22PB, this model might offer slight variations in features, such as an enhanced communication interface or a different control algorithm, making it suitable for applications with specific requirements.

- KOLLMORGEN 80WKS-CE240/22PB: With a higher output power of 80 W, this model is designed for applications that demand more power, such as driving larger motors in heavy – duty manufacturing equipment.

- KOLLMORGEN Servo Motors: These motors are specifically designed to pair with the KOLLMORGEN 60WKS-CE240/22PBservo drive. Different motor models offer varying torque and speed capabilities, allowing for customized motion control solutions based on application needs.

- KOLLMORGEN Motion Control Software: This software provides an intuitive interface for programming and configuring the KOLLMORGEN 60WKS-CE240/22PB. It enables users to easily set up complex motion profiles, monitor drive performance in real – time, and perform diagnostics, enhancing the overall usability and functionality of the motion control system.

- KOLLMORGEN Encoders: High – precision encoders from KOLLMORGEN work in tandem with the KOLLMORGEN 60WKS-CE240/22PBto provide accurate feedback on motor position and speed. Different encoder models offer varying resolutions and interfaces, ensuring compatibility with different application requirements.

Installation and Maintenance

Pre – installation preparation: Before installing the KOLLMORGEN 60WKS-CE240/22PB, carefully review the installation manual provided by KOLLMORGEN. Ensure that the installation site meets the environmental requirements, including temperature and humidity conditions. Verify that the input power supply matches the specified 240 V AC (±10%) and is properly grounded. Mount the drive on a suitable surface using the provided mounting hardware, ensuring that there is sufficient space around it for proper ventilation. Connect the power cables, motor cables, and communication cables according to the wiring diagram in the manual, and double – check all connections to ensure they are secure.

Maintenance recommendations: Regularly inspect the KOLLMORGEN 60WKS-CE240/22PB for any signs of physical damage, loose connections, or abnormal operation. Clean the drive periodically using a dry, soft cloth to remove dust, which can affect its heat dissipation. Monitor the operating temperature of the drive during operation; if it exceeds the specified range, check for proper ventilation and ensure that the load on the drive is within its rated capacity. Periodically update the drive’s firmware as recommended by KOLLMORGEN to benefit from the latest features, performance improvements, and security enhancements. In case of any malfunctions, such as communication errors or inconsistent motor control, refer to the troubleshooting guide in the user manual or contact KOLLMORGEN’s technical support team for assistance.

Product Guarantee

KOLLMORGEN is committed to the quality and reliability of the KOLLMORGEN 60WKS-CE240/22PB. The product is backed by a comprehensive quality assurance program that adheres to strict international standards. KOLLMORGEN offers a standard warranty period, during which any manufacturing defects will be promptly addressed with free repair or replacement services. Their dedicated technical support team, consisting of experts with in – depth knowledge of motion control systems, is available to assist customers with installation, operation, and maintenance. Whether customers encounter technical issues, need advice on system integration, or have questions about product performance, KOLLMORGEN’s support ensures timely and effective solutions, reflecting the company’s confidence in the product and its commitment to customer satisfaction in the motion control industry.