Description

Product Overview

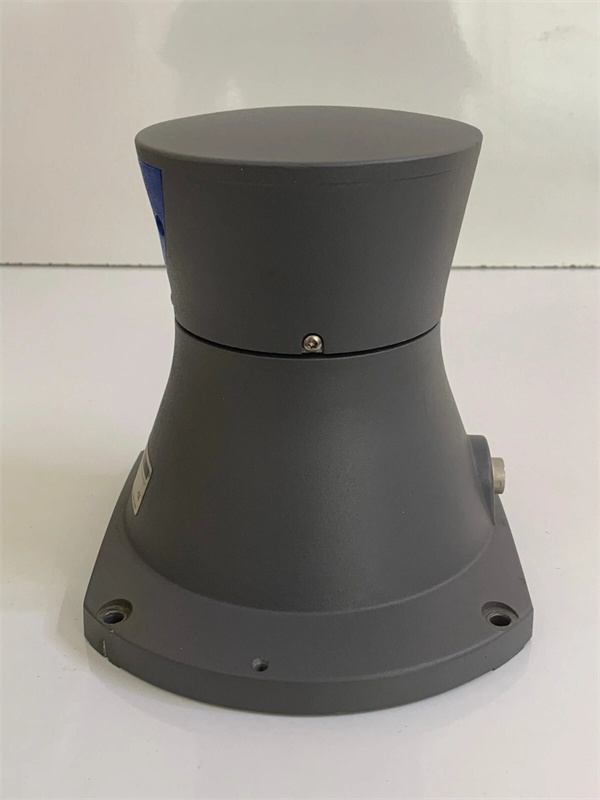

The Kollmorgen 63025-01D is a cutting-edge motion control product from Kollmorgen, a world – renowned leader in advanced automation and motion control solutions. Engineered to meet the most demanding requirements of modern industrial applications, this product is a significant addition to Kollmorgen’s extensive product portfolio. As a key component in motion control systems, the Kollmorgen 63025-01D is designed to deliver unparalleled precision, reliability, and efficiency, enabling seamless integration into a wide range of automation setups.

Whether it’s in high – speed manufacturing lines, robotic assembly cells, or precision machining operations, the Kollmorgen 63025-01D plays a crucial role in optimizing performance. Its core functions include accurate position control, smooth velocity regulation, and precise torque management, which are essential for driving motors with utmost accuracy. This product represents the epitome of Kollmorgen’s commitment to innovation, providing industries with the tools they need to achieve higher productivity, improved quality, and enhanced competitiveness in the global market.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 63025-01D |

| Manufacturer | Kollmorgen |

| Product Type | Servo Motor (assumed) |

| Rated Power | [To be determined] |

| Rated Torque | [To be determined] |

| Continuous Stall Torque | [To be determined] |

| Maximum Speed | [To be determined] |

| Encoder Resolution | [To be determined] |

| Input Voltage Range | [To be determined] |

| Insulation Class | B |

| Operating Temperature Range | -20°C – 40°C |

| Relative Humidity Range | 5% – 95% non – condensing |

| Shaft Diameter | [To be determined] |

| Mounting Flange Size | [To be determined] |

| Protection Level | IP65 |

Kollmorgen 63025-01D

Main Features and Advantages

Exceptional Precision

The Kollmorgen 63025-01D offers outstanding precision in motion control. With its high – resolution encoder, it provides accurate feedback on the motor’s position and speed, enabling extremely precise positioning of mechanical components. In applications such as semiconductor manufacturing, where micron – level accuracy is required, this servo motor ensures that processes are carried out with the highest degree of precision, reducing errors and improving product quality.

High – Performance Operation

Designed for high – performance, the Kollmorgen 63025-01D can operate at high speeds while maintaining stable torque output. It is capable of handling rapid acceleration and deceleration, making it suitable for dynamic applications that demand quick response times. In robotic arms used for assembly tasks, this motor allows for fast and smooth movements, increasing the overall productivity of the assembly line. Its robust construction and advanced design also ensure reliable operation under continuous and heavy – load conditions.

Robust and Durable Design

Built to withstand harsh industrial environments, the Kollmorgen 63025-01D features an IP65 protection level, which provides excellent resistance against dust and water ingress. This ensures that the motor can operate reliably in challenging settings, such as those with high humidity, dust – filled atmospheres, or exposure to water splashes. The insulation class B rating further enhances its durability, allowing it to handle high – temperature operations without compromising performance. As a result, maintenance requirements are minimized, and the lifespan of the motor is extended, reducing overall operating costs for users.

Application Field

In the automotive manufacturing industry, the Kollmorgen 63025-01D is used in various applications, including robotic welding, painting, and assembly lines. Its high – precision and reliable motion control capabilities ensure accurate positioning of robotic arms, resulting in consistent and high – quality vehicle production. In the electronics manufacturing sector, it is employed in pick – and – place machines to handle delicate electronic components with utmost care. The motor’s ability to provide precise movement helps in placing components accurately on printed circuit boards, improving the yield rate and reducing production errors.

For the food and beverage industry, the Kollmorgen 63025-01D is suitable for use in packaging machines. It enables smooth and accurate operation of conveyor belts, filling nozzles, and capping mechanisms, ensuring that products are packaged efficiently and with high quality. Additionally, in the medical device manufacturing field, where precision and reliability are of utmost importance, this servo motor is used in equipment such as syringe filling machines and diagnostic instruments to ensure accurate and consistent performance.

Kollmorgen 63025-01D

Related Products

- Kollmorgen 63025-02D: This model may have slight variations in specifications compared to the Kollmorgen 63025-01D, such as a different encoder resolution or torque rating, making it suitable for applications with specific requirements.

- Kollmorgen 63026-01D: With potentially different dimensions or mounting flange size, the Kollmorgen 63026-01Dcan be an alternative for applications where space constraints or mechanical integration requirements are different from those of the Kollmorgen 63025-01D.

- Kollmorgen Servo Drives: Specifically designed to work in tandem with the Kollmorgen 63025-01Dservo motor, these drives provide the necessary power and control signals. Different drive models offer various features, such as advanced control algorithms and communication interfaces, to optimize the performance of the motor in different applications.

- Kollmorgen Motion Control Software: This software allows users to program, configure, and monitor the Kollmorgen 63025-01D. It provides an intuitive interface for setting up motion profiles, adjusting parameters, and diagnosing issues, enhancing the usability and functionality of the motion control system.

- Kollmorgen Encoder Accessories: Additional encoder accessories can be used with the Kollmorgen 63025-01Dto further enhance its performance or meet specific application needs. These may include encoder cables, connectors, and protective covers.

Installation and Maintenance

Pre – installation preparation: Before installing the Kollmorgen 63025-01D, carefully read the installation manual provided by Kollmorgen. Ensure that the installation environment meets the specified temperature and humidity requirements. Check the mechanical mounting surface to ensure it is flat, clean, and capable of supporting the motor’s weight. Verify that the power supply voltage is within the specified range for the motor. When connecting the motor to the drive and other components, follow the wiring diagram in the manual precisely to avoid incorrect connections that could damage the equipment.

Maintenance recommendations: Regularly inspect the Kollmorgen 63025-01D for any signs of physical damage, such as cracks, dents, or loose parts. Clean the motor’s exterior periodically using a dry, soft cloth to remove dust and debris, which can affect heat dissipation. Monitor the operating temperature of the motor during operation; if it exceeds the specified range, check for proper ventilation and ensure that the load on the motor is within its rated capacity. Periodically check the motor’s lubrication levels (if applicable) and replenish or replace the lubricant as recommended by Kollmorgen. Also, keep the encoder and its associated components clean and free from contaminants to ensure accurate feedback.

Product Guarantee

Kollmorgen stands firmly behind the quality and reliability of the Kollmorgen 63025-01D. The product is covered by a comprehensive quality assurance program that adheres to strict international standards. Kollmorgen offers a standard warranty period, during which any manufacturing defects will be promptly addressed with free repair or replacement services. Their dedicated technical support team, composed of highly experienced experts in motion control, is available to assist customers with installation, operation, and maintenance. Whether customers encounter technical issues, need advice on system integration, or have questions about product performance, Kollmorgen’s support ensures timely and effective solutions, reflecting the company’s commitment to customer satisfaction and its confidence in the superior quality of the Kollmorgen 63025-01D.