Description

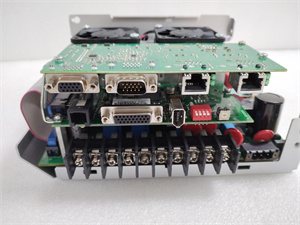

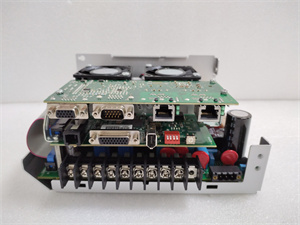

KOLLMORGEN S22460-SRS Servo Drive Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | S22460-SRS |

| Manufacturer | KOLLMORGEN |

| Product category | Servo Drive |

| Supply voltage | 120/240 VAC, 20 – 90 VDC |

| Rated current | 6 Amps RMS continuous to 96 Amps RMS peak |

| Feedback resolution | 24 – bit multi – turn absolute |

| Current loop bandwidth | Up to 8 kHz |

| Communication protocols | EtherCAT, PROFINET, CANopen, Modbus TCP, SynqNet (optional) |

| Control modes | Torque, speed, position, electronic gearing, and cam profiles |

| Ambient operating temperature | -20℃ – 55℃ |

| Protection degree | IP20 |

| Installation method | DIN – rail mount or panel – mount |

Product introduction

The KOLLMORGEN S22460-SRS servo drive is a top – tier offering within the esteemed S200 series, setting new benchmarks in industrial automation. As a high – performance servo drive, it is meticulously engineered to deliver precise and reliable control of servo motors, making it an essential component for complex automation systems. The S22460-SRS integrates state – of – the – art technology with a rugged design, ensuring its suitability for a vast array of industrial applications.

Equipped with a 24 – bit multi – turn absolute feedback resolution, the KOLLMORGEN S22460-SRS provides highly accurate and continuous position information, enabling unparalleled motion control. Its remarkable current loop bandwidth of up to 8 kHz ensures ultra – fast response times and smooth operation, even in the most demanding high – speed and dynamic scenarios. With support for multiple communication protocols such as EtherCAT, PROFINET, and CANopen, the S22460-SRS can seamlessly integrate into diverse control architectures. Moreover, its extensive control modes, including electronic gearing and cam profiles, offer enhanced flexibility to meet the specific requirements of different applications.

The S22460-SRS also features an intuitive commissioning interface and advanced self – diagnostic functions, which streamline the setup and maintenance processes, reducing downtime and improving overall system efficiency.

Core advantages and technical highlights

Unmatched performance

The KOLLMORGEN S22460-SRS stands out for its exceptional performance capabilities. With an 8 kHz current loop bandwidth, it can handle rapid changes in motion commands, allowing for high – speed and highly precise operation. The 24 – bit multi – turn absolute feedback provides continuous and accurate position data, enabling the drive to maintain tight control over the servo motor, minimizing errors and enhancing the quality of the overall automation process. This makes it ideal for applications that demand the highest levels of precision and speed, such as high – speed pick – and – place operations.

Versatile communication and control

The wide range of supported communication protocols gives the S22460-SRS remarkable versatility. Whether it’s integrating with a PROFINET – based factory automation network or an EtherCAT – enabled high – speed motion control system, this drive can adapt effortlessly. Its control modes, including electronic gearing and cam profiles, offer advanced motion control capabilities. Electronic gearing allows for precise synchronization of different axes, while cam profiles enable the creation of complex motion patterns, making it suitable for a wide variety of industrial machinery, from packaging equipment to textile looms.

Robust and reliable operation

Designed to withstand harsh industrial environments, the S22460-SRS has an extended operating temperature range of -20℃ – 55℃. The IP20 protection degree safeguards it from dust and accidental contact. Its intelligent self – diagnostic functions continuously monitor the drive’s performance, detecting potential issues early and triggering protective actions. This proactive approach to reliability, combined with its rugged construction, ensures that the S22460-SRS can operate continuously with minimal maintenance, reducing costly downtime in industrial production lines.

Typical application scenarios

In the aerospace manufacturing industry, the KOLLMORGEN S22460-SRS is indispensable for the assembly of complex aircraft components. The drive’s high – precision motion control is crucial for tasks such as drilling, riveting, and precision machining, ensuring that parts are fabricated to exacting tolerances. The ability to handle advanced motion profiles and integrate seamlessly with other automation systems on the production floor enhances productivity and quality control.

For the food and beverage packaging industry, the S22460-SRS plays a vital role in the operation of high – speed packaging lines. Its rapid response times and accurate control of servo motors enable precise movement of packaging materials, such as filling containers, applying labels, and sealing packages. The support for multiple communication protocols allows for easy integration with other machines on the line, ensuring smooth coordination and maximizing production throughput.

In the metalworking industry, the KOLLMORGEN S22460-SRS is used to control the motion of CNC machines. The high – performance feedback system and advanced control modes ensure that the cutting tools move with extreme precision, resulting in high – quality finished products. The drive’s ability to operate in a wide temperature range and its reliable performance make it suitable for the demanding environment of metalworking factories.

Related model recommendations

- S21260-SRS: From the same S200 series, S21260-SRShas lower current ratings than S22460-SRS. It serves as a suitable option for applications with less power – intensive requirements, while sharing many of the advanced features and communication capabilities of the S22460-SRS.

- S20360-SRS: Another member of the S200 series, S20360-SRSoffers basic functionality and is designed for entry – level automation tasks. It can be considered a more cost – effective alternative when the high – performance features of S22460-SRS are not fully required.

- AKM4G – ANCNR – 00(servo motor): This servo motor pairs perfectly with the S22460-SRS. Together, they deliver high – torque output and precise motion control, making them a great choice for heavy – duty industrial applications like large – scale material handling systems.

- RMP500 – 15(motion controller): When integrated with the S22460-SRS, the RMP500 – 15 motion controller unlocks even more advanced motion control capabilities. It allows for complex multi – axis programming and synchronization, enhancing the performance of high – end automation systems.

- 6SM68S – 8.000 – G(feedback device): This high – accuracy feedback device can be used in conjunction with the S22460-SRS to further boost position feedback precision, especially beneficial for applications where sub – micron level accuracy is required, such as semiconductor manufacturing.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the KOLLMORGEN S22460-SRS, ensure the installation area is clean, dry, and well – ventilated, free from excessive dust and electrical interference sources. Confirm that the ambient temperature is within the -20℃ – 55℃ range. Gather essential tools like screwdrivers, wire strippers, and multimeters. When handling the drive, use anti – static wrist straps or mats to protect sensitive electronic components. The drive can be mounted on a DIN – rail or panel following the provided installation diagrams, ensuring all electrical connections are correctly wired, tightened, and properly insulated.

Maintenance suggestions

For regular maintenance of the S22460-SRS, frequently check for signs of physical damage, loose connections, or abnormal vibrations. Utilize the drive’s built – in diagnostic functions to monitor its operating temperature, current, and other performance parameters. In case of a fault, refer to the detailed troubleshooting guide. When replacing components, always use genuine KOLLMORGEN parts to maintain optimal performance and reliability. Clean the drive’s ventilation slots regularly to prevent dust accumulation, which can impact cooling efficiency and lead to overheating issues.

Service and guarantee commitment

KOLLMORGEN stands firmly behind the quality of the S22460-SRS servo drive. The product comes with a comprehensive quality assurance program that guarantees its performance meets the highest industry standards. In the event of a defect covered by the warranty, KOLLMORGEN provides a hassle – free replacement or repair service. Their dedicated technical support team is available 24/7 to assist customers with installation, commissioning, and any technical issues. Whether through remote support or on – site service, KOLLMORGEN is committed to minimizing downtime and ensuring that customers can rely on the S22460-SRS for their industrial automation needs, demonstrating its unwavering dedication to customer satisfaction.