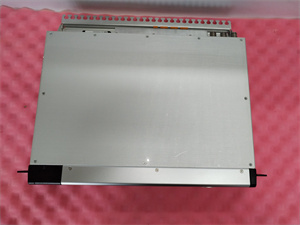

Description

KONGSBERG DPS112

**

1. General Introduction

KONGSBERG, a distinguished Norwegian company with a rich history spanning over two centuries, has carved a niche as a global technology powerhouse. Specializing in providing cutting – edge solutions across diverse sectors like oil and gas, maritime, aerospace, and defense, KONGSBERG’s products are renowned for their reliability and innovation. The DPS112, although details are currently scarce, is likely a high – performance component designed to meet the stringent demands of these industries. Leveraging the company’s extensive expertise, it could potentially play a crucial role in power management, data processing, or system control.

2. Possible Product Categories and Technical Parameters

2.1. Maritime Power Supply Unit (Hypothetical)

- Product Model: DPS112

- Manufacturer: KONGSBERG

- Product Category: High – Efficiency Marine Power Supply

- Input Voltage: Capable of operating with a wide input voltage range, such as 90 – 264 VAC, to accommodate different shipboard power systems. This flexibility ensures compatibility with various vessels, from small yachts to large commercial ships.

- Output Voltage and Current: Provides a stable output voltage, for example, 24 VDC, with a rated output current of 12 amps. This output is suitable for powering a variety of maritime electronics, including navigation equipment, communication systems, and sensors.

- Efficiency: Boasts high – efficiency power conversion, with an efficiency rating of up to 92%. This not only reduces energy consumption but also minimizes heat generation, enhancing the reliability and lifespan of the power supply in the often – harsh marine environment.

- Protection Features: Equipped with comprehensive protection mechanisms, including over – voltage protection, under – voltage protection, over – current protection, and short – circuit protection. These safeguards prevent damage to the power supply and the connected equipment, ensuring uninterrupted operation even in the face of electrical anomalies.

- Environmental Adaptability: Designed to withstand the challenging marine environment, with an operating temperature range of – 20℃ to 60℃. It is also resistant to humidity, salt – spray, and vibration, having an IP65 protection rating, which effectively shields it from dust and water jets from any direction.

KONGSBERG DPS112

2.2. Aerospace Data Processing System (Hypothetical)

- Product Model: DPS112

- Manufacturer: KONGSBERG

- Product Category: High – Speed Aerospace Data Processor

- Data Processing Capacity: Capable of handling large volumes of data at high speeds, with a processing rate of up to 1 billion operations per second. This allows it to quickly analyze and process data from various aerospace sensors, such as those monitoring aircraft performance, engine parameters, and environmental conditions.

- Communication Interfaces: Features advanced communication interfaces, including ARINC 664 and MIL – STD – 1553B. ARINC 664 enables high – speed, reliable data transfer within the aircraft’s avionics network, while MIL – STD – 1553B provides a standardized interface for communication with other aerospace systems, ensuring seamless integration.

- Memory and Storage: Equipped with a significant amount of onboard memory, such as 16GB of high – speed RAM and 128GB of flash storage. This allows it to store and process large datasets, including flight data records, sensor logs, and software algorithms, for real – time decision – making and post – flight analysis.

- Redundancy and Reliability: Incorporates redundant components and systems to enhance reliability. In case of a component failure, redundant modules can automatically take over, ensuring continuous operation without interruption. This is crucial for maintaining the safety and functionality of aerospace systems during flight.

- Operating Environment: Built to withstand the extreme conditions of aerospace operations, with an operating temperature range of – 55℃ to 125℃. It is also highly resistant to radiation and electromagnetic interference, ensuring stable performance in the complex aerospace environment.

2.3. Defense – related Power Distribution System (Hypothetical)

- Product Model: DPS112

- Manufacturer: KONGSBERG

- Product Category: Secure Military Power Distribution Unit

- Power Distribution: Capable of distributing power to multiple military devices and systems, with multiple output channels that can be independently controlled. It can handle a wide range of power requirements, from low – power communication devices to high – power weapons systems.

- Voltage Regulation: Provides precise voltage regulation, ensuring that the output voltage remains stable even under varying load conditions. This is essential for the proper functioning of sensitive military electronics, which are often critical for mission success.

- Security Features: Incorporates advanced security features to protect the power distribution system from unauthorized access and cyber threats. It may use encryption algorithms, authentication mechanisms, and intrusion detection systems to safeguard the integrity of the power supply and the connected devices.

- Mobility and Durability: Designed to be rugged and portable, suitable for military field operations. It has a shock – resistant and waterproof housing, with an IP67 rating, allowing it to be used in harsh environmental conditions, including rain, dust, and extreme temperatures. It is also lightweight and easy to transport, with convenient mounting options for installation on military vehicles or in field shelters.

- Power Efficiency: Optimized for power efficiency, with low standby power consumption and high – efficiency power conversion. This helps to conserve energy, especially important in military operations where power sources may be limited or difficult to replenish.

KONGSBERG DPS112

3. Core Advantages and Technical Highlights

3.1. High – Quality and Reliability

As a product of KONGSBERG, the DPS112 is likely to be built with top – quality materials and components. The company’s stringent quality control processes ensure that the DPS112 undergoes extensive testing, including environmental testing, stress testing, and reliability testing. In the maritime context, it would be tested for long – term durability in simulated sea conditions, while in aerospace and defense applications, it would be subjected to extreme conditions to guarantee its performance under real – world scenarios.

3.2. Advanced Technology Integration

KONGSBERG’s commitment to technological innovation means that the DPS112 would likely incorporate the latest advancements. In a maritime power supply, it could use advanced power electronics technology, such as digital power factor correction and soft – switching techniques, for more efficient power conversion. In an aerospace data processing system, it might utilize the latest multi – core processor technology and high – speed data interfaces for enhanced data handling capabilities. In a defense – related power distribution system, it could integrate cutting – edge security technologies to protect against emerging cyber threats.

3.3. Customizability

Given the diverse requirements of different industries and customers, the DPS112 may offer a high degree of customizability. KONGSBERG’s engineering team can tailor the product to specific needs, whether it’s adjusting the power output and voltage levels for a maritime application, customizing the data processing algorithms for an aerospace system, or modifying the security features for a defense – related deployment.

4. Typical Application Scenarios

4.1. Maritime Applications

- Ship Navigation and Communication: In a large cargo ship, the DPS112, as a marine power supply, would provide stable power to the ship’s navigation equipment, such as GPS receivers, radar systems, and electronic chart display and information systems (ECDIS). It would also power the communication systems, including VHF radios, satellite communication devices, and onboard Wi – Fi networks, ensuring seamless communication and navigation during long voyages.

- Offshore Platform Operations: On an offshore oil and gas platform, the DPS112 could supply power to various critical systems, such as drilling equipment, pumps, compressors, and monitoring sensors. Its reliable power output and protection features would ensure the continuous operation of these systems, even in the harsh offshore environment.

4.2. Aerospace Applications

- Commercial Aircraft Avionics: In a commercial airliner, the DPS112, as an aerospace data processor, would play a vital role in the aircraft’s avionics system. It would process data from multiple sensors, including those monitoring engine performance, aircraft altitude, speed, and attitude. This data would be used to control various aircraft systems, such as the flight control surfaces, engine management, and cabin environmental control, ensuring safe and efficient flight operations.

- Military Aircraft Systems: In a military fighter jet, the DPS112 could be responsible for processing data from advanced sensors, such as radar, infrared sensors, and electro – optical sensors. It would analyze this data in real – time to support mission – critical functions, such as target detection, tracking, and engagement, enhancing the aircraft’s combat effectiveness.

4.3. Defense Applications

- Field – Based Military Operations: During a military field operation, the DPS112, as a secure military power distribution unit, would be used to power a variety of military devices, including portable radios, night – vision goggles, laptops, and weapons systems. Its security features would protect the power supply from enemy interference, ensuring that the military equipment remains operational when needed most.

- Military Command and Control Centers: In a military command and control center, the DPS112 could distribute power to the center’s communication networks, data servers, and display systems. It would also ensure the reliable operation of critical control systems, enabling commanders to make informed decisions and coordinate military operations effectively.

5. Related Product Recommendations

5.1. KONGSBERG Maritime Automation Systems

If the DPS112 is a maritime power supply, it could be integrated with KONGSBERG’s maritime automation systems. These systems, which include vessel control, engine monitoring, and power management functions, would benefit from the reliable power provided by the DPS112. Together, they would enhance the overall efficiency and safety of maritime operations.

5.2. KONGSBERG Avionics Systems

For an aerospace – related DPS112, it could be paired with KONGSBERG’s avionics systems. These avionics systems, designed for aircraft navigation, communication, and flight control, would work in harmony with the data processing capabilities of the DPS112, improving the performance and reliability of the aircraft’s avionics suite.

5.3. KONGSBERG Defense Communication and Control Systems

In the defense sector, the DPS112 could be used in conjunction with KONGSBERG’s defense communication and control systems. These systems, which enable secure communication and effective command and control in military operations, would rely on the stable power supply and security features of the DPS112 to ensure seamless operation.

6. Installation, Commissioning, and Maintenance Instructions

6.1. Installation Preparation

- Environmental Check: Before installation, carefully assess the installation environment. For maritime installations, ensure that the location is free from excessive moisture, salt – spray, and mechanical vibrations. In aerospace installations, verify that the area meets the temperature, pressure, and electromagnetic compatibility requirements. In defense applications, consider the potential exposure to dust, water, and extreme temperatures, and ensure that the installation site provides adequate protection.

- Tool and Equipment Preparation: Gather the necessary tools and equipment for installation, such as screwdrivers, wrenches, wire strippers, and multimeters. In aerospace and defense installations, ensure that the tools meet the specific safety and quality standards required for these industries.

- Safety Precautions: Adhere to strict safety procedures during installation. In all applications, ensure that the power source is turned off and properly grounded to prevent electrical shocks. In maritime installations, take precautions to prevent water ingress, while in aerospace and defense installations, follow the relevant safety regulations and guidelines to avoid damage to the equipment and ensure the safety of personnel.

- Documentation Review: Thoroughly review the installation manual provided by KONGSBERG. Familiarize yourself with the product’s wiring diagrams, mounting instructions, and safety warnings. Ensure that you understand the installation process and any specific requirements for the DPS112 in your particular application.

6.2. Commissioning

- Power – On Checks: After installation, perform a series of power – on checks. Verify that the input voltage is within the specified range and that the DPS112 powers on correctly. Check for any error indicators or abnormal behavior, and refer to the troubleshooting guide if necessary.

- Function Testing: Conduct comprehensive function tests to ensure that the DPS112 is operating as expected. In a maritime power supply, test the output voltage and current stability under different load conditions. In an aerospace data processing system, verify the data processing speed and accuracy by running test algorithms and analyzing the results. In a defense – related power distribution system, test the power distribution to different devices and the effectiveness of the security features.

- Calibration and Configuration: If required, perform calibration and configuration procedures to optimize the performance of the DPS112. This may involve adjusting the voltage settings, configuring the communication interfaces, or setting up the security parameters. Follow the instructions in the installation manual carefully to ensure proper calibration and configuration.

6.3. Maintenance

- Regular Inspections: Schedule regular inspections of the DPS112 to check for any signs of wear, damage, or abnormal operation. In maritime applications, inspect for corrosion and water ingress. In aerospace and defense applications, look for signs of physical damage, loose connections, or overheating.

- Cleaning and Dust Removal: Keep the DPS112 clean to prevent dust and debris from accumulating, which can affect its performance and lifespan. Use appropriate cleaning methods and materials, and avoid using solvents or abrasive cleaners that could damage the equipment.

- Component Replacement: If any components of the DPS112 show signs of failure or wear, replace them promptly with genuine KONGSBERG parts. Follow the replacement procedures outlined in the maintenance manual to ensure proper installation and functionality.

- Software Updates: If the DPS112 has software – based features, regularly check for software updates from KONGSBERG. Install the updates as recommended to improve performance, fix bugs, and enhance security.