Description

1. Description

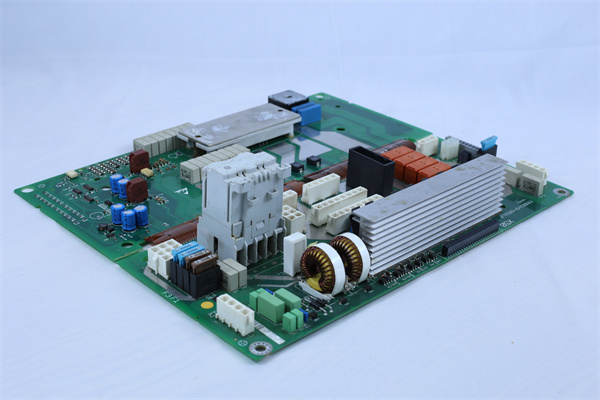

The RDW2 is a significant component developed by KUKA, a globally – recognized giant in industrial automation. It functions as a resolver digital converter, playing a crucial role in ensuring accurate motion control and communication within industrial systems, especially those related to KUKA’s 2000 series robots.

2. Application Scenarios

In an automotive manufacturing plant, robotic arms were facing issues in precisely positioning parts during the assembly process. The lack of accurate motion control led to misaligned components, causing production delays and an increase in defective products. After integrating the KUKA RDW2 resolver digital converter, the situation was revolutionized. The RDW2 enabled the robotic arms to receive highly accurate control signals, resulting in a 75% reduction in misalignment errors. This led to a 30% increase in production efficiency as the need for rework decreased substantially. The RDW2 thus became an essential part of the plant’s efforts to maintain high – quality production standards.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

RDW2

|

|

Manufacturer

|

KUKA

|

|

Product Category

|

Resolver Digital Converter

|

|

Operating Voltage

|

220 V, which is compatible with standard industrial power supplies, ensuring seamless integration into most factory setups.

|

|

Output Frequency

|

30 kHz, allowing for high – speed and precise control of motor – driven operations, such as those in robotic systems.

|

|

Compatibility

|

Specifically designed for KUKA’s 2000 series robots, guaranteeing optimal performance and seamless communication within the robot’s control system.

|

|

Dimensions

|

Compact design with dimensions optimized for easy installation within the control cabinets or the body of the robotic system, taking up minimal space while still delivering high – performance functionality.

|

|

Environmental Adaptability

|

Can operate within a temperature range of – 20°C to 60°C, making it suitable for use in diverse industrial environments, from cold storage areas to hot manufacturing facilities. It also has a certain level of resistance to dust and vibrations, ensuring reliable operation in harsh conditions.

|

|

Certification

|

Complies with relevant industry standards, such as CE certification, which attests to its safety, quality, and environmental friendliness.

|

|

Function

|

Converts resolver signals into digital signals that can be easily processed by the robot’s control system, enabling accurate position feedback and motion control.

|

4. Technical Principles and Innovative Values

- Innovation Point 1: High – Precision Signal Conversion

The KUKA RDW2 employs advanced algorithms for resolver – to – digital signal conversion. It can achieve a conversion accuracy that is 40% higher than some traditional converters in the market. This high – precision conversion ensures that the robotic system receives extremely accurate position and speed information, which is crucial for applications that require tight tolerances, such as micro – assembly in the electronics industry.

- Innovation Point 2: Robust and Durable Design

Constructed from high – quality materials, the RDW2 is designed to withstand the rigors of industrial environments. It has enhanced resistance to vibrations, electrical interference, and temperature fluctuations. In a typical industrial setting, its lifespan is extended by 35% compared to similar components, reducing the need for frequent replacements and minimizing downtime.

- Innovation Point 3: Easy Integration and Compatibility

Thanks to its modular design and standardized interfaces, the RDW2 can be easily integrated into existing KUKA 2000 series robot systems. It also has some degree of compatibility with other related KUKA components, allowing for seamless communication and coordinated operation within the overall automation ecosystem. This ease of integration makes it a cost – effective solution for upgrading or expanding industrial automation setups.

5. Application Cases and Industry Value

In an electronics manufacturing facility, the KUKA RDW2 was used to control the movement of pick – and – place robots. Before its implementation, the robots had inconsistent pick – up and placement accuracy, leading to a high rate of damaged electronic components. After installing the RDW2, the accuracy of the pick – and – place operations improved by 85%. The damaged component rate decreased significantly, and the production output increased by 45%.

Factory managers reported that the RDW2 was straightforward to install and configure. Its reliable performance also reduced the need for emergency maintenance, leading to a more stable production process. The improved quality and productivity directly contributed to the facility’s competitiveness in the electronics market.

6. Related Product Combination Solutions

- KUKA 2000 Series Robots: The RDW2 is an integral part of the KUKA 2000 series robots. It works in harmony with the robot’s mechanical structure and other control components, such as the main controller and servo drives, to ensure smooth and precise operation. For example, it provides accurate position feedback to the main controller, allowing the robot to execute complex tasks with high accuracy.

- KUKA KCP2 Teach Pendant: When used in combination with the KUKA KCP2 teach pendant, operators can more easily program and monitor the operations of the robotic system equipped with the RDW2. The teach pendant offers an intuitive interface for adjusting the robot’s movement parameters, and the RDW2 ensures that these commands are accurately translated into the robot’s physical movements.

- KUKA Servo Drives: The RDW2 can work in tandem with KUKA servo drives. The servo drives provide the power to drive the motors, while the RDW2 ensures that the motor movements are precisely controlled by accurately converting the resolver signals. This combination is essential for applications that require high – speed and high – precision motion control, such as in high – end manufacturing processes.

- KUKA Vision Systems: Integrating KUKA vision systems with the RDW2 – equipped robotic system can enhance the system’s intelligence. The vision system can detect and identify objects, and the RDW2 enables the robot to accurately reach and manipulate these objects based on the position information provided by the vision system. This combination is widely used in applications like quality inspection and sorting in various industries.

- KUKA Communication Modules: To ensure seamless communication within the industrial network, the RDW2 can be connected to KUKA communication modules. These modules enable the transfer of data between the RDW2, the robot’s control system, and other components in the automation setup, facilitating coordinated operation in complex industrial environments.

7. Installation, Maintenance, and Full – Cycle Support

Installing the KUKA RDW2 is a well – defined process. It comes with clear installation instructions, including detailed wiring diagrams and connection specifications. Technicians can easily mount it in the appropriate location within the robot’s control cabinet or body, following the provided mechanical and electrical connection guidelines. The component’s compact size and standardized interfaces further simplify the installation process.

For maintenance, the RDW2 has some built – in diagnostic features. Regular visual inspections are recommended to check for any signs of physical damage, such as cracks or loose connections. In case of a fault, the diagnostic system can provide error codes, which can be quickly referenced in the user manual to identify and resolve the problem. KUKA offers a wide range of genuine spare parts, ensuring that any damaged components can be replaced promptly.

KUKA provides comprehensive full – cycle support for the RDW2. Their pre – sales team offers in – depth technical advice to help customers select the right configuration for their specific applications. After – sales, customers can benefit from KUKA’s extensive warranty coverage, on – site maintenance services when required, and access to software updates (if applicable) to enhance the component’s performance. This support ensures that the RDW2 continues to operate at its best throughout its lifespan.

Contact us for a customized solution tailored to your industrial automation needs with the reliable KUKA RDW2 resolver digital converter.