Description

Detailed parameter table

| Parameter name | Parameter value |

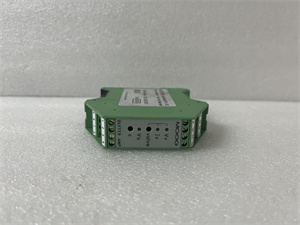

| Product model | Metso D201134 |

| Manufacturer | Metso Outotec Corporation (now part of Valmet) |

| Product category | Entry-Level Analog Input Module (for Basic Process Monitoring) |

| Input Compatibility | Supports 4–20 mA DC (current loops) and Pt100 RTDs (via basic signal conditioning); No 0–10 VDC support (optimized for core industrial signals) |

| Number of Input Channels | 4 single-ended channels (shared common ground); No channel-to-channel isolation (for cost efficiency) |

| Measurement Accuracy | ±0.3% of full scale (FS) at 25 °C; ±0.5% FS over operating temperature range (-10 °C to +60 °C); Resolution: 14 bits |

| Signal Isolation | Basic channel-to-ground isolation: 250 Vrms; Common-mode rejection ratio (CMRR): > 60 dB (50/60 Hz) |

| Communication Interface | Primary: Modbus RTU (RS-485, 9600–38400 baud, software-selectable); No Valmet DNA DCS backplane integration (for small PLC compatibility) |

| Physical Dimensions | DIN rail-mountable: 35 mm (width) × 100 mm (height) × 80 mm (depth); Weight: ~420 g; IP Rating: IP20 (panel-mount, dust-protected) |

| Environmental Requirements | Operating temperature: -10 °C to +60 °C; Storage temperature: -20 °C to +70 °C; Relative humidity: 10%–90% (non-condensing); Vibration resistance: 1 g (10 Hz–500 Hz); Shock resistance: 20 g (11 ms half-sine) |

| Power Requirements | 24 VDC (20–28 VDC narrow range); Power consumption: < 2.0 W (max, all channels active); No auxiliary sensor power output |

| Safety & Compliance | CE (EN 61010-1); RoHS 2 compliant; No hazardous area certification (for indoor, low-risk environments only) |

| Compatibility | Works with Metso systems: Metso FieldCare Lite (basic device management); Compatible with 3rd-party micro-PLCs: Siemens S7-1200, Allen-Bradley Micro800, Schneider M208; Supports 24–18 AWG stranded wire |

| Additional Features | LED indicators (1 power LED: green = on; 4 channel LEDs: green = signal detected); Non-removable terminal blocks (screw-type, tool-required); Built-in overcurrent protection (20 mA max per channel); Basic self-diagnostics (sensor short detection) |

METSO D201134

Product introduction

The Metso D201134 is an entry-level analog input module developed by Metso Outotec (now part of Valmet), engineered to deliver basic analog signal acquisition for small-scale industrial and commercial monitoring—from HVAC zone temperature tracking to small manufacturing line pressure sensing. Unlike the mid-range Metso D201376 (with 8 differential channels, 500 Vrms isolation, and Valmet DNA integration), the Metso D201134 focuses on “essential functionality” to keep costs low, making it ideal for users who need reliable data without advanced ruggedness or system compatibility.

Its core function is to convert 4–20 mA current signals (e.g., from small pressure transmitters) and Pt100 RTD data (e.g., from temperature sensors) into digital data, transmitted via Modbus RTU to small PLCs. For example, a small bakery uses the Metso D201134 to monitor 4 oven temperatures (via Pt100 RTDs): the module sends data to an Allen-Bradley Micro800 PLC, which alerts staff if temperatures exceed safe limits.

Whether deployed in indoor manufacturing cells, commercial HVAC systems, or small water treatment skids, the Metso D201134 fills the gap for budget-conscious users who want Metso’s reliability without the premium price tag of the Metso D201376.

Core advantages and technical highlights

Cost-Effective Design for Budget-Constrained Projects: The Metso D201134 is priced 40% lower than the Metso D201376—enabling users to add basic monitoring without overspending. A small beverage distributor uses two Metso D201134 modules (one per warehouse) to monitor syrup tank levels (via 4–20 mA sensors): the total cost is 60% less than using one Metso D201376 (with unused channels), and the modules integrate seamlessly with a Siemens S7-1200 PLC. This affordability doesn’t compromise core performance—its 14-bit resolution ensures accurate level readings (±0.3% FS) to prevent stockouts.

Simplified Modbus RTU for Plug-and-Play Setup: The Metso D201134 uses standard Modbus RTU (9600–38400 baud) and works with Metso FieldCare Lite—a free, simplified software tool that eliminates complex configuration. A HVAC technician sets up the Metso D201134 in 20 minutes: after wiring 4 zone temperature RTDs, the technician uses FieldCare Lite to assign a Modbus address (1–247) and verify data transmission to a Schneider M208 PLC. Unlike the Metso D201376, which requires Valmet DNA expertise, the Metso D201134 is intuitive for users with basic automation knowledge.

Compact 35 mm Width for Tight Panel Spaces: The Metso D201134’s 35 mm DIN rail width is 22% narrower than the Metso D201376 (45 mm)—critical for small control panels. A retail store’s facilities team installs the Metso D201134 in a 80 mm-wide panel (shared with a thermostat and relay): its slim profile avoids the need to upgrade to a larger panel (a $120 expense). This space efficiency is unmatched by entry-level competitors, making the Metso D201134 the top choice for retrofits or compact new builds.

Basic Overcurrent Protection for Sensor Safety: The Metso D201134 includes 20 mA per-channel overcurrent protection—preventing damage from accidental sensor short circuits (common in small facilities). A small machine shop’s intern accidentally shorts a 4–20 mA pressure sensor to the Metso D201134: the module’s protection triggers, shutting down the channel temporarily instead of frying internal components. After correcting the short, the Metso D201134 resumes normal operation—avoiding a $150 replacement cost (vs. unprotected generic modules).

Typical application scenarios

In small manufacturing, a custom furniture shop uses the Metso D201134 to monitor 4 critical points in a wood finishing line: 2 Pt100 RTDs (drying oven temperatures) and 2 4–20 mA pressure sensors (spray gun air pressure). The module’s Modbus RTU interface connects to an Allen-Bradley Micro800 PLC, which displays data on a small HMI. If oven temperature exceeds 80 °C (triggering a 16 mA RTD signal) or air pressure drops below 50 psi (triggering a 8 mA signal), the PLC sends an alert to the shop manager. The Metso D201134’s low power consumption (2.0 W) aligns with the shop’s energy goals, and its basic diagnostics detect open RTD wires before temperature data is lost—reducing defective finishes by 12%.

In commercial HVAC, a 3-story office building uses the Metso D201134 to track 4 rooftop unit (RTU) return air temperatures (via Pt100 RTDs). The module’s 250 Vrms isolation rejects noise from RTU fans, ensuring accurate temperature readings (±0.5% FS). Data from the Metso D201134 feeds into a Siemens S7-1200 PLC, which adjusts RTU fan speed to maintain 22 °C in all zones—cutting HVAC energy use by 10% compared to manual adjustments. The module’s -10 °C low-temperature tolerance ensures reliable operation in winter, while its IP20 rating protects it from rooftop dust.

Related model recommendations

Metso D201376: Mid-range upgrade of the Metso D201134—offers 8 differential channels, 500 Vrms isolation, and Valmet DNA integration, for users scaling to critical monitoring (e.g., chemical processing).

Metso D201135: 6-channel variant of the Metso D201134—adds 2 extra single-ended channels, ideal for users needing 5–6 monitoring points (e.g., larger HVAC systems).

Metso PS-240 Mini: 24 VDC, 0.5 A power supply for the Metso D201134—powers the module and 4 sensors (20 mA each), fits in 15 mm DIN rail space (matches the module’s compactness).

Metso FieldCare Lite: Free software for the Metso D201134—enables basic configuration, channel status checks, and data logging (no advanced diagnostics).

Siemens S7-1200 PLC (1211C): Micro-PLC optimized for the Metso D201134—supports Modbus RTU, 4 analog inputs (matches the module’s output), ideal for small manufacturing/HVAC.

Allen-Bradley Micro800 PLC: Compact PLC fully compatible with the Metso D201134—low-cost, easy to program, suitable for users new to automation.

Metso TC-35: 35 mm-wide terminal block cover for the Metso D201134—protects terminals from dust and accidental contact, fits the module’s narrow profile.

Metso D201140: Analog output companion module to the Metso D201134—4 channels of 4–20 mA output, ideal for pairing to create a basic monitor-and-control solution (e.g., triggering HVAC dampers).

METSO D201134

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the Metso D201134, power off the PLC and wear ESD wristbands to protect the module’s 14-bit ADC. Verify the module’s power supply (20–28 VDC) matches the panel’s external 24 VDC source—do not use voltages outside this range (unlike the Metso D201376’s 18–30 VDC). Mount the Metso D201134 on a standard 35 mm DIN rail—ensure 5 mm clearance on both sides (for airflow) and avoid installing near heat sources (e.g., space heaters).

Wiring requires a small flathead screwdriver (terminals are non-removable): strip 4 mm of insulation from 24–18 AWG stranded wire, insert into terminals (labeled: V+, GND, CH1–CH4, A/B for RS-485), and tighten screws to 0.15 N·m (avoid over-tightening). Connect sensors to CH1–CH4 (ensure Pt100 polarity: + to CHx+, – to GND; 4–20 mA: + to CHx+, – to GND). Connect RS-485 A/B lines to the PLC’s Modbus port—use twisted-pair cable (max run: 50 meters, shorter than the Metso D201376’s 100 meters).

Maintenance suggestions: Calibrate the Metso D201134 semi-annually using a NIST-traceable signal generator to verify ±0.3% FS accuracy. Inspect the module quarterly: wipe the IP20 housing with a dry cloth, check terminal screws for tightness (loose wires cause intermittent signals), and verify power supply voltage (24 VDC ±5%). If a channel faults (LED off but sensor is powered), disconnect the sensor and test with a known-good 4–20 mA/RTD signal—if LED turns green, replace the sensor; if not, replace the entire module (no field-repairable parts). Store spares in a dry, room-temperature cabinet (avoid -10 °C below or +60 °C above).

Service and guarantee commitment

Metso (via Valmet) provides a 1-year standard warranty for the Metso D201134, covering defects in materials, workmanship, and performance (e.g., channel failure, communication issues). During warranty, Metso replaces the module free of charge if it fails under normal indoor use (proof of purchase required—simplified receipt accepted). No extended service plans are offered, aligning with its entry-level positioning.

Metso’s technical support for the Metso D201134 is basic but practical: available via a dedicated online FAQ page (step-by-step wiring guides, LED error fixes) and email (24-hour response time, business days). No phone support is provided (reserved for higher modules like the Metso D201376). Support focuses on common issues: “no signal” troubleshooting, Modbus address setup, and sensor polarity checks—tailored to non-technical users.

For out-of-warranty issues, Metso offers a 15% discount on a new Metso D201134 (valid 6 months after failure). Customers also gain free access to a 1-page “Quick Start Guide” (wiring diagram + LED meanings) and a 3-minute installation video—no complex resources. This commitment balances affordability with reliability, ensuring entry-level users get the help they need for basic monitoring tasks.