Description

Detailed parameter table

| Parameter name | Parameter value |

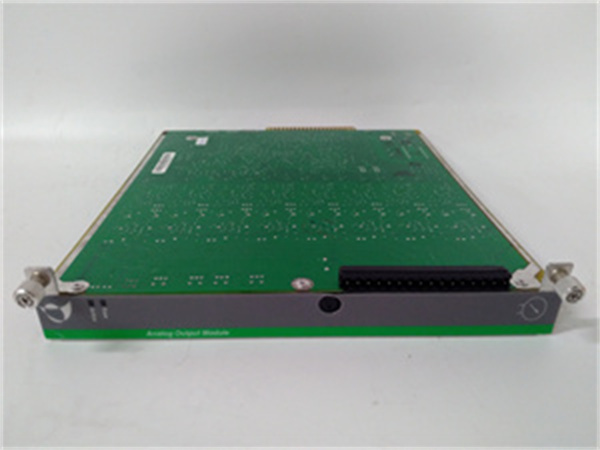

| Product model | Metso IOP320 |

| Manufacturer | Metso Outotec Corporation |

| Product category | High-performance Analog Output Module |

| Operating voltage | 220 V (AC); Also available in a 24 VDC option for low-voltage applications |

| Output frequency | 30 kHz (optimized for high-speed response in dynamic processes) |

| Analog output range | 0 – 20 mA (standard industrial range for seamless integration with most sensors and actuators); 4 – 20 mA option for enhanced noise immunity in long-wire installations |

| Current load capacity | Up to 3 A (capable of driving high-power actuators directly, reducing the need for additional amplifiers); 1 A per channel for multi-channel operation |

| Response time | Less than 1 ms (ultra-fast response for real-time control, ensuring minimal lag in process adjustments) |

| Environmental resistance | IP65 (dust-tight and water-jet resistant, suitable for harsh industrial environments, including outdoor and washdown areas); Meets NEMA 4X equivalent standards |

| Operating temperature | -20 °C to +70 °C (wide temperature range for reliable operation in extreme climates, from cold storage facilities to hot industrial plants) |

| Certification | UL (Underwriters Laboratories) for safety compliance in North America; CE (Conformité Européene) for European market access; ISO 9001 (quality management system certified, ensuring consistent high-quality manufacturing) |

| Communication Interface | Modbus RTU (RS-485, 1200 – 115200 baud, software-selectable parity) for basic control system integration; Optional Profibus DP for high-speed, high-reliability industrial networks; HART (Highway Addressable Remote Transducer) compatibility for enhanced diagnostic and configuration capabilities |

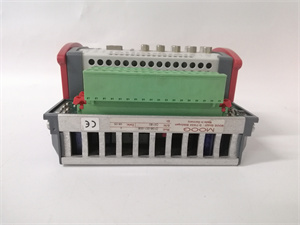

| Physical Dimensions | Compact DIN rail form factor: 50 mm (width) × 120 mm (height) × 80 mm (depth) for easy installation in standard control panels; Weight: ~650 g (lightweight yet robust construction); Mounting options: DIN rail, panel-mount (with optional brackets) |

| Additional Features | LED status indicators for each channel (green = normal operation, red = fault, yellow = calibration required); Built-in over-current and short-circuit protection for enhanced reliability; Removable terminal blocks for easy wiring and maintenance (24 – 16 AWG wire compatibility); Factory-calibrated for out-of-the-box accuracy, with field calibration option for fine-tuning |

METSO IOP320

Product introduction

The Metso IOP320 is a high-performance analog output module meticulously engineered by Metso Outotec to meet the stringent demands of industrial control applications. As a key component in process automation, its primary function is to convert digital control signals from a PLC or DCS system into precise analog outputs, enabling seamless control of various industrial actuators such as valves, variable frequency drives (VFDs), and analog gauges.

Designed for seamless integration into a wide range of automation systems, the IOP320 ensures reliable operation even under the most extreme conditions. Whether it’s a high-temperature furnace in a steel mill or a humid chemical processing plant, the module’s robust construction and advanced engineering make it a trusted choice for industries that require uncompromising accuracy and durability.

Unlike some competing modules that may struggle with signal integrity over long distances, the Metso IOP320’s 4 – 20 mA output option is specifically designed to maintain signal quality in installations with extended wiring runs. This feature, combined with its high current load capacity and fast response time, makes it an ideal solution for applications where split-second control decisions can have a significant impact on process efficiency and product quality.

Core advantages and technical highlights

Unparalleled Precision in Analog Signal Transmission

The Metso IOP320 offers exceptional precision in analog signal output, with a resolution of up to 16 bits. This high level of accuracy ensures that even the most minute control adjustments are faithfully translated into corresponding analog signals, enabling precise regulation of industrial processes. For example, in a pharmaceutical manufacturing plant, the IOP320 is used to control the flow rate of critical chemicals in a mixing process. The module’s precise output allows for tight control of the chemical ratios, resulting in consistent product quality and reduced waste.

Robust IP65-Rated Enclosure for Harsh Environments

Encased in an IP65-rated enclosure, the Metso IOP320 is well-protected against dust, water jets, and other environmental contaminants. This makes it suitable for use in a wide range of industrial settings, including outdoor installations, food and beverage processing plants, and mining operations. In a food processing facility, the IOP320 is installed in a washdown area to control the speed of conveyor belts. The module’s water-resistant design ensures reliable operation even when exposed to frequent cleaning with high-pressure water jets.

HART Compatibility for Enhanced Interoperability

The IOP320’s HART compatibility enables seamless integration with existing network protocols, enhancing system interoperability and efficiency. HART technology allows for two-way communication between the module and other HART-enabled devices, such as intelligent sensors and control systems. This enables remote configuration, calibration, and diagnostic capabilities, reducing the need for on-site maintenance and troubleshooting. In a power generation plant, the IOP320 is used to control the output of a steam turbine. The HART interface allows plant operators to remotely monitor and adjust the turbine’s performance parameters, optimizing energy production and reducing downtime.

Compact Design for Easy Installation and Maintenance

Despite its high-performance capabilities, the Metso IOP320 features a compact design that facilitates easy installation and maintenance. The module’s DIN rail mounting option allows for quick and secure installation in standard control panels, while its removable terminal blocks make wiring and component replacement a breeze. In a small manufacturing facility, the IOP320 is installed in a crowded control panel to control the operation of several small motors. The module’s compact size and easy-to-access terminals make it easy to integrate into the existing system without requiring major modifications.

Typical application scenarios

Chemical Processing

In a chemical processing plant, the Metso IOP320 is used to control the opening and closing of control valves in a reaction vessel. The module’s precise analog output ensures accurate control of the chemical feed rates, optimizing the reaction process and minimizing the risk of over- or under-reaction. The IOP320’s robust construction and environmental resistance make it suitable for use in the harsh chemical environment, while its HART compatibility enables remote monitoring and adjustment of the valve settings.

Power Generation

In a power generation plant, the IOP320 is used to control the speed and output of a gas turbine. The module receives digital control signals from the plant’s DCS system and converts them into precise analog signals to regulate the turbine’s fuel injection and combustion process. The IOP320’s fast response time and high accuracy ensure smooth and efficient operation of the turbine, maximizing power generation and minimizing fuel consumption. The module’s reliability and durability are crucial in this application, as any downtime can result in significant financial losses.

Food and Beverage Manufacturing

In a food and beverage manufacturing plant, the Metso IOP320 is used to control the filling level of bottles and cans on a packaging line. The module’s analog output is used to adjust the speed of the filling machine, ensuring consistent fill levels and minimizing product waste. The IOP320’s IP65-rated enclosure makes it suitable for use in the hygienic environment of a food and beverage plant, while its easy installation and maintenance features help to reduce downtime and keep production running smoothly.

METSO IOP320

Related model recommendations

Metso IOP321: A lower-cost, entry-level analog output module with 4 channels, suitable for small-scale applications where fewer outputs are required. It offers basic functionality similar to the IOP320 but with a more compact form factor and reduced feature set.

Metso IOP330: A digital output module that can be paired with the IOP320 to create a comprehensive control solution. The IOP330 provides discrete digital outputs for controlling relays, solenoids, and other digital devices, complementing the analog control capabilities of the IOP320.

Metso FieldCare 4.0: Device management software for the IOP320 that enables remote configuration, calibration, and diagnostic monitoring. It simplifies the management of multiple IOP320 modules across a plant, reducing the need for on-site maintenance and improving overall system efficiency.

Metso DNA Lite: A compact DCS system that seamlessly integrates with the IOP320, providing centralized control and monitoring of industrial processes. It offers a user-friendly interface and advanced control algorithms, making it suitable for small to medium-sized plants.

Metso Surge Protection Module (SP-320): An accessory that can be added to the IOP320 to provide additional protection against voltage surges and electrical interference. It helps to safeguard the module from damage in high-noise environments, such as those near industrial motors or power distribution systems.

Siemens S7-1500 PLC: A popular third-party PLC that is fully compatible with the Metso IOP320. It offers high-performance processing capabilities and a wide range of communication options, making it a versatile choice for industrial automation projects.

Allen-Bradley CompactLogix: Another well-known PLC that works seamlessly with the IOP320. It provides reliable control and is widely used in various industries, offering a range of features and expansion options.

Metso Terminal Block Extension (TB-320): An accessory that adds additional terminals to the IOP320, useful for applications that require more wiring connections or for creating redundant wiring configurations.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Metso IOP320, ensure that the power to the control system is turned off to prevent electrical shock. Wear appropriate ESD (electrostatic discharge) protection, such as an ESD wristband, to avoid damaging the module’s sensitive electronics. Verify that the operating voltage of the module (either 220 VAC or 24 VDC) matches the power source in the control panel.

Mount the IOP320 on a standard 35 mm DIN rail using the provided mounting brackets. Ensure that there is sufficient clearance around the module for proper ventilation and access for maintenance. Use the removable terminal blocks to connect the input and output wires. Strip the ends of the wires to the appropriate length (24 – 16 AWG) and insert them into the terminals. Secure the wires using the built-in terminal screws.

Connect the communication wires (RS-485 for Modbus RTU or Profibus DP) to the appropriate terminals on the module, following the wiring diagram provided in the user manual. If using the HART interface, connect the HART-compatible devices according to the HART protocol specifications.

Commissioning and maintenance

After installation, power on the control system and verify that the IOP320’s power LED illuminates green, indicating normal power supply. Use a multimeter to check the analog output signals at the module’s terminals. Apply a known digital input signal to the module and measure the corresponding analog output to ensure that it falls within the expected range.

Use the Metso FieldCare software or the control system’s built-in diagnostic tools to configure the module’s parameters, such as output range, communication settings, and calibration factors. Verify that the module is communicating correctly with the control system and other connected devices.

For maintenance, periodically inspect the module for any signs of physical damage, such as cracks in the enclosure or loose wires. Clean the module using a soft, dry cloth to remove dust and debris. Check the terminal connections regularly and tighten any loose screws. If a channel on the module fails, first check the wiring and connections to the affected device. If the problem persists, use the Metso FieldCare software to perform diagnostic tests on the module.

If a terminal block needs to be replaced, simply remove the old terminal block by loosening the mounting screws and disconnecting the wires. Install the new terminal block (spare part: TB-320-SP) and reconnect the wires. Calibrate the module if necessary, following the calibration procedure outlined in the user manual.

Service and guarantee commitment

Metso provides a 2-year standard warranty for the Metso IOP320, covering defects in materials, workmanship, and performance. During the warranty period, Metso will repair or replace the module free of charge if it is found to be defective.

For commercial customers, Metso offers the Metso Essential Service Plan, which extends the warranty coverage to 3 years. The plan also includes annual remote diagnostic checks via Metso FieldCare, priority technical support with an 8-hour response time during business hours, and discounted replacement parts.

Metso’s technical support team is available to provide assistance with installation, configuration, troubleshooting, and maintenance of the IOP320. Customers can contact the support team via phone, email, or the online support portal. Metso also provides a wealth of online resources, including user manuals, application notes, and technical documentation, to help customers make the most of their IOP320 modules.

For out-of-warranty repairs, Metso’s regional service centers offer flat-rate repair services with a 5-business-day turnaround time for most issues. The service centers are staffed by trained technicians who use genuine Metso replacement parts to ensure the highest quality repairs. This commitment to service and support reflects Metso’s confidence in the durability and reliability of the IOP320 and its dedication to meeting the needs of its customers.