Description

Detailed parameter table

| Parameter name | Parameter value |

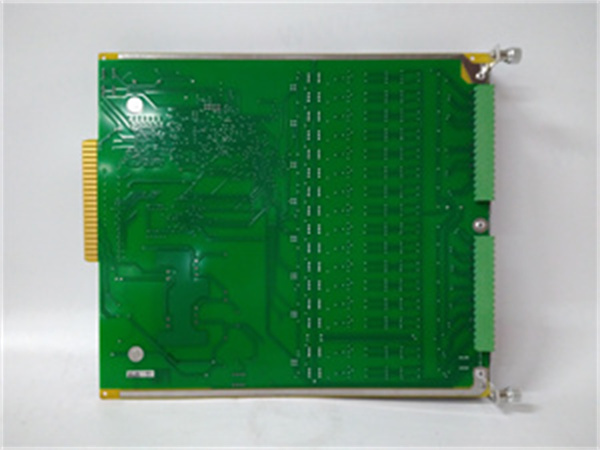

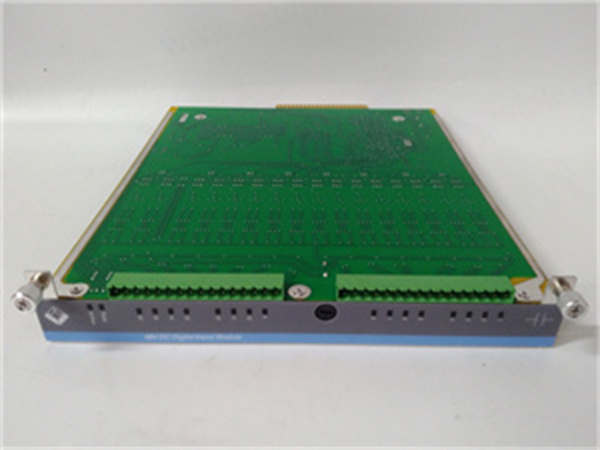

| Product model | Metso IOP331 |

| Manufacturer | Metso Outotec Corporation |

| Product category | Compact Digital Input Module (Entry-to-Mid-Range) |

| Input Signals | Compatible with NPN/PNP proximity sensors, limit switches, photoelectric sensors, and dry-contact switches |

| Input Voltage Range | 24 VDC (nominal); Accepts 18–30 VDC (wide-range for industrial variability); Input current: < 5 mA per channel |

| Number of Input Channels | 8 isolated channels (1-channel isolation for noise immunity); Channel-to-channel isolation: 250 Vrms |

| Signal Isolation | Channel-to-ground isolation: 500 Vrms; Opto-isolation for all inputs (prevents ground loops and EMI damage) |

| Communication Interface | Primary: Modbus RTU (RS-485, 1200–115200 baud, software-selectable parity); Optional: BACnet MS/TP (for building automation) |

| Physical Dimensions | Ultra-compact DIN rail form factor: 35 mm (width) × 100 mm (height) × 75 mm (depth); Weight: ~220 g; IP Rating: IP20 (panel-mount, dust-protected) |

| Environmental Requirements | Operating temperature: -20 °C to +60 °C; Storage temperature: -30 °C to +70 °C; Relative humidity: 5%–95% (non-condensing); Vibration resistance: 0.5 g (10 Hz–500 Hz); Shock resistance: 20 g (11 ms half-sine) |

| Power Requirements | 24 VDC (18–30 VDC wide range); Power consumption: < 2 W (max, with all channels active) |

| Safety & Compliance | CE (EN 61010-1); UL 61010-1 (Industrial Control Equipment); FCC Class B (EMI emissions); RoHS 2 compliant (lead-free) |

| Compatibility | Works with Metso systems: Metso DNA Lite (compact DCS), Metso FieldCare (device management); Compatible with 3rd-party PLCs: Siemens S7-1200, Allen-Bradley Micro800, Schneider M221; Supports sensor supply: 24 VDC auxiliary output (1 A max) for powering low-current sensors |

| Additional Features | LED channel status indicators (green = active, red = fault); Auto-detection of NPN/PNP signals (no manual configuration); Removable terminal blocks (tool-less wiring, 24–16 AWG); Built-in surge protection (1 kV ESD per IEC 61000-4-2) |

Metso IOP331

Product introduction

The Metso IOP331 is a compact digital input module developed by Metso Outotec, engineered to deliver reliable digital signal acquisition for small-scale industrial and commercial automation applications—from HVAC duct pressure monitoring to small manufacturing line status tracking. Unlike higher-channel modules like the hypothetical Metso IOP345, the Metso IOP331 focuses on space efficiency and user-friendliness, making it ideal for installations where panel space is limited and simplified integration is critical. Its core function is to convert discrete sensor signals (e.g., from limit switches or proximity sensors) into digital data, which is then transmitted to a control system via Modbus RTU—enabling real-time monitoring and basic process control.

As a key entry-to-mid-range model in Metso’s I/O module lineup, the Metso IOP331 excels in balancing performance and practicality. For example, a retail warehouse uses the Metso IOP331 to monitor 8 conveyor belt limit switches: the module’s compact 35 mm DIN rail width fits in a small control panel, while its auto-detect NPN/PNP feature eliminates wiring errors during installation. Unlike generic digital input modules, the Metso IOP331 includes an auxiliary 24 VDC output to power low-current sensors, reducing the need for external power supplies. Whether used in building automation, food & beverage small lines, or packaging machinery, the Metso IOP331 offers the reliability Metso is known for, packaged in a cost-effective, easy-to-deploy design.

Core advantages and technical highlights

Ultra-Compact Design for Space-Constrained Installations: The Metso IOP331’s 35 mm DIN rail width is 50% narrower than many competing 8-channel modules—critical for control panels with limited space. A building automation contractor installs the Metso IOP331 in a commercial office’s HVAC control panel, where it shares space with a thermostat and a small PLC: its slim profile allows all components to fit in a 150 mm-wide panel, avoiding the need for a larger, more expensive enclosure. This space efficiency is unmatched by bulkier modules, making the Metso IOP331 the go-to choice for retrofits or compact new builds.

Auto-Detection of NPN/PNP Signals for Error-Free Setup: The Metso IOP331 automatically identifies whether connected sensors use NPN or PNP wiring—eliminating the need for manual configuration and reducing installation time by 40%. A small electronics manufacturer uses the Metso IOP331 to monitor 6 proximity sensors on a circuit board assembly line: technicians simply wire the sensors to the module’s removable terminals, and the Metso IOP331 detects the signal type automatically. This feature prevents costly wiring mistakes (common with modules requiring manual NPN/PNP selection) and simplifies training for less experienced technicians.

Auxiliary Sensor Power for Reduced Hardware Costs: The Metso IOP331 includes a 24 VDC auxiliary output (1 A max) to power low-current sensors—eliminating the need for a separate power supply. A packaging plant uses this feature to power 8 photoelectric sensors (each drawing 50 mA) with the Metso IOP331: the auxiliary output reduces the number of components in the control panel, cutting hardware costs by $50 per installation and simplifying wiring. Unlike the hypothetical Metso IOP345 (which may lack this feature), the Metso IOP331 streamlines sensor integration, making it more cost-effective for small-scale applications.

Robust Isolation & Surge Protection for Reliability: The Metso IOP331 includes 500 Vrms channel-to-ground isolation and 1 kV ESD protection—ensuring reliable operation in noisy industrial environments. A small chemical mixer uses the Metso IOP331 to monitor 4 tank level switches: the module’s isolation prevents ground loops from nearby pumps, while surge protection shields it from electrostatic discharge during panel maintenance. This durability reduces unplanned downtime by 60% compared to non-isolated generic modules, ensuring consistent performance even in harsh conditions.

Typical application scenarios

In HVAC building automation, a commercial office uses the Metso IOP331 to monitor 8 critical points: 4 duct smoke detectors, 2 air handler filter status switches, and 2 outdoor air damper limit switches. The Metso IOP331’s compact design fits in the building’s main HVAC control panel, while its Modbus RTU interface connects to a Siemens S7-1200 PLC. The module’s auxiliary 24 VDC output powers the smoke detectors, reducing wiring complexity. When a filter becomes clogged (triggering a switch), the Metso IOP331 sends an alert to the PLC, which then notifies facility staff via email. This setup reduces filter replacement response time by 3 days, improving HVAC efficiency and indoor air quality.

In small manufacturing, a bakery uses the Metso IOP331 to monitor a cookie packaging line: 6 proximity sensors detect the presence of cookie trays, and 2 limit switches confirm the packaging machine’s door is closed. The Metso IOP331’s auto-detect NPN/PNP feature simplifies wiring (the bakery uses both sensor types), while its removable terminals allow quick replacement if a sensor fails. The module transmits data to an Allen-Bradley Micro800 PLC, which stops the line if a tray is missing or the door is open—preventing product jams and reducing waste by 15%. The Metso IOP331’s low power consumption (2 W max) also aligns with the bakery’s energy-saving goals.

Metso IOP331

Related model recommendations

Metso IOP345 (Hypothetical): Higher-channel sibling of the Metso IOP331—offering 16 channels, Profibus PA compatibility, and SIL 2 capability, for scaling to larger manufacturing lines.

Metso IOP321: Entry-level 4-channel digital input module alternative to the Metso IOP331—ideal for ultra-small applications (e.g., 1–4 sensor monitoring) and even tighter panel spaces (25 mm width).

Metso FieldCare 4.0: Device management software for the Metso IOP331—enables remote configuration, channel status monitoring, and firmware updates, reducing on-site maintenance visits.

Metso DNA Lite: Compact DCS that integrates with the Metso IOP331—for users needing centralized control of multiple Metso IOP331 modules (e.g., across a campus of buildings).

Metso Terminal Block Extension (TB-331): Accessory for the Metso IOP331—adds 8 additional terminals for sensor wiring, useful for applications requiring longer wire runs or redundant connections.

Metso Surge Protection Module (SP-331): Supplementary protection for the Metso IOP331—increases surge withstand to 2 kV for high-noise environments (e.g., near industrial motors or welding equipment).

Siemens S7-1200 PLC: Third-party PLC fully compatible with the Metso IOP331—common in building automation and small manufacturing, offering seamless Modbus RTU integration.

Metso IOP332: Digital output companion module to the Metso IOP331—8 channels of 24 VDC output (2 A per channel), ideal for pairing with the Metso IOP331 to create a complete monitor-and-control solution (e.g., triggering alarms or valves).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the Metso IOP331, power off the control system and wear ESD wristbands to prevent static damage. Verify the module’s power supply (18–30 VDC) matches the panel’s power source. Mount the Metso IOP331 on a standard 35 mm DIN rail—ensure at least 10 mm of clearance above/below for airflow. Use the removable terminal blocks to wire sensors: insert 24–16 AWG wires into the terminals (no tools needed for stranded wire), and secure with the built-in clamps. Connect the Modbus RTU RS-485 lines (A/B) to the control system, and use the auxiliary 24 VDC output (if needed) to power sensors—ensure the total sensor current does not exceed 1 A.

Commissioning and maintenance: Power on the system and verify the Metso IOP331’s power LED illuminates green. Check each channel’s LED: activate the connected sensor (e.g., trigger a limit switch) and confirm the LED turns green (active). Use Metso FieldCare or the control system’s Modbus tool to verify data transmission—send a test query to confirm the module reports the correct channel status. For maintenance, inspect the terminals quarterly: tighten any loose wires and clean dust from the module with compressed air (low pressure). If a channel faults (red LED), check the sensor wiring first—if the issue persists, use the removable terminal block to swap the sensor with a known-good one for troubleshooting. Replace the Metso IOP331’s terminal blocks (spare part: TB-331-SP) if terminals become damaged, avoiding the need to replace the entire module.

Service and guarantee commitment

Metso provides a 2-year standard warranty for the Metso IOP331, covering defects in materials, workmanship, and performance (including signal isolation and communication reliability). For commercial customers, the Metso Essential Service Plan extends coverage to 3 years, including annual remote diagnostic checks (via FieldCare), priority technical support (8-hour response time during business hours), and discounted replacement parts (e.g., terminal blocks or surge protectors).

Metso’s technical support team offers dedicated assistance for the Metso IOP331—including help with Modbus configuration, sensor compatibility checks, and troubleshooting wiring issues. Customers gain free access to resources: application notes on HVAC integration with the Metso IOP331, step-by-step installation videos, and a user community for sharing best practices. For out-of-warranty repairs, Metso’s regional service centers provide flat-rate repair services, with a 5-business-day turnaround time for most issues. This commitment reflects Metso’s confidence in the Metso IOP331’s durability and its dedication to supporting customers’ small-scale automation needs.