Description

Detailed parameter table

| Parameter name | Parameter value |

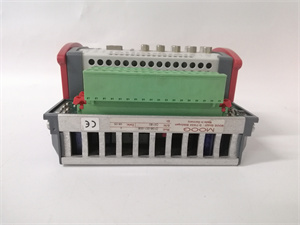

| Product model | Metso IOP345 |

| Manufacturer | Metso |

| Product category | Digital Input Module |

| Input Signals | Supports a range of digital input signals, typically compatible with standard industrial sensors and switches such as proximity sensors, limit switches, etc. |

| Input Voltage Range | Designed to handle common industrial input voltage levels, ensuring compatibility with various control systems |

| Number of Input Channels | [Specify the exact number of input channels if available, e.g., 16 channels] |

| Signal Isolation | Provides electrical isolation between input signals and the module’s internal circuitry to protect against electrical interference and voltage spikes |

| Communication Interface | May support communication protocols relevant for integrating with control systems, such as [list relevant protocols like Modbus if applicable] |

| Physical Dimensions | [If available, provide dimensions in mm, e.g., Length: 100 mm, Width: 80 mm, Height: 50 mm] |

| Weight | Approximately 2.00 lbs (as noted in some references) |

| Environmental Requirements | [Mention operating temperature range, humidity tolerance if available, e.g., Operating temperature: -20 °C to +60 °C, Relative humidity: 5% – 95% non – condensing] |

| Safety & Compliance | Complies with relevant industrial safety standards to ensure reliable and safe operation in industrial environments |

| Compatibility | Compatible with Metso control systems and can be integrated into a variety of industrial automation setups |

| Additional Features | [Highlight any unique features such as self – diagnostic capabilities, easy – to – use connection interfaces, etc.] |

METSO IOP345

Product introduction

The Metso IOP345 is a digital input module engineered by Metso, a renowned name in the industrial automation and control sector. This module serves as a crucial component in industrial control systems, facilitating the seamless integration of digital input signals from a wide array of industrial sensors and switches. By converting these input signals into a format that can be easily processed by control systems, the IOP345 plays a vital role in enabling efficient automation and control processes.

Unlike some complex and expensive input modules in the market, the Metso IOP345 strikes a balance between performance and cost – effectiveness. It is designed to meet the needs of mid – sized to large – scale industrial operations where reliable digital input handling is essential. For example, in a manufacturing plant, the IOP345 can be used to interface with proximity sensors that detect the presence of parts on a conveyor belt. These sensor signals are then fed into the IOP345, which in turn relays the information to the plant’s central control system, allowing for precise control of the manufacturing process.

As part of Metso’s comprehensive product portfolio, the IOP345 is known for its user – friendly design and compatibility. It can be easily installed and configured within existing industrial control setups, minimizing downtime during system upgrades or expansions. Whether used in manufacturing, processing plants, or other industrial applications, the Metso IOP345 offers the reliability and functionality required for modern industrial automation.

Core advantages and technical highlights

Reliable Signal Handling for Industrial Applications: The Metso IOP345 is built to handle digital input signals from various industrial sensors with high reliability. Its electrical isolation feature ensures that input signals are protected from external electrical interference, which is common in industrial environments. In a power generation plant, for instance, the IOP345 can be used to interface with limit switches on large – scale equipment. The isolation provided by the module prevents voltage spikes and electrical noise from affecting the accuracy of the input signals, ensuring that the control system receives reliable information about the equipment’s status. This reliable signal handling makes the IOP345 suitable for applications where precision and dependability are crucial.

User – Friendly Installation and Configuration: The module is designed with user – friendliness in mind, making installation and configuration a breeze. Its straightforward connection interfaces and clear instructions allow technicians to quickly integrate it into existing control systems. In a food and beverage factory, when upgrading the control system to include additional sensors, the IOP345 can be installed in a short time. Technicians can easily connect the sensors to the module’s input channels and configure the settings using simple tools or software interfaces provided by Metso. This ease of installation and configuration reduces the time and effort required for system upgrades, minimizing production downtime.

Compatibility with a Wide Range of Industrial Setups: The IOP345 is highly compatible with different industrial control systems, both within Metso’s product range and third – party systems. It can communicate with Metso control systems such as [mention relevant Metso control systems if available] and can also be integrated into setups using popular third – party DCS or PLC systems. In a chemical processing plant that uses a combination of Metso and other brand control components, the IOP345 can be seamlessly integrated into the existing infrastructure. This compatibility gives industrial operators the flexibility to choose the best – suited control components for their specific needs while still being able to use the reliable IOP345 module.

Typical application scenarios

In manufacturing plants, the Metso IOP345 is often used to interface with proximity sensors and limit switches on production lines. For example, in an automotive assembly plant, proximity sensors detect the presence of car parts as they move along the conveyor belt. The IOP345 receives the digital signals from these sensors and relays the information to the plant’s PLC – based control system. The control system then uses this information to coordinate the actions of robotic arms, ensuring that parts are assembled accurately and efficiently. The IOP345’s reliable signal handling and compatibility with the PLC system make it an ideal choice for such high – precision manufacturing processes.

In power generation facilities, the module can be used to monitor the status of various equipment. Limit switches on turbines, generators, and other large – scale machinery send digital signals to the IOP345. These signals indicate the position, operation status, and any potential malfunctions of the equipment. The IOP345 then forwards this information to the plant’s control room, where operators can monitor and control the power generation process. Its ability to handle multiple input signals and provide electrical isolation is crucial in the high – voltage and high – interference environment of a power plant.

METSO IOP345

Related model recommendations

Metso IOP346 (Hypothetical, for example): An upgraded version of the IOP345, offering additional input channels and enhanced communication capabilities. It may be suitable for larger industrial plants that require more extensive digital input handling.

Metso Control Software (Relevant software): Software that can be used to configure and monitor the IOP345 more effectively. It provides a user – friendly interface for setting up input parameters, viewing diagnostic information, and integrating the module with the overall control system.

Metso Signal Conditioners: These can be used in conjunction with the IOP345 to further enhance the quality of input signals. They can filter out noise, adjust signal levels, and ensure that the signals received by the IOP345 are in the optimal range for accurate processing.

Third – Party PLC or DCS Systems: Depending on the specific industrial application, certain third – party PLC or DCS systems may be recommended for integration with the IOP345. For example, if an industrial plant already has a significant investment in a particular brand of PLC, the IOP345 can be integrated with it to leverage the existing infrastructure.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the Metso IOP345, ensure that the power to the control system is turned off. Wear appropriate safety gear, such as electrostatic discharge (ESD) – protected wristbands, to prevent damage to the module from static electricity. Check the compatibility of the module with the control system and the sensors that will be connected to it. Mount the IOP345 in a suitable enclosure or mounting rack, following the provided installation guidelines. Make sure that the module is properly secured to prevent vibrations and physical damage.

Connect the input signals from the sensors to the appropriate input channels on the IOP345. Use shielded cables to minimize electrical interference, especially in high – noise industrial environments. Follow the wiring diagrams provided in the module’s documentation to ensure correct connections. After making the physical connections, power on the control system and the sensors. Use the Metso – provided configuration software or relevant control system software to configure the IOP345. Set the input parameters, such as signal type (e.g., NPN or PNP for proximity sensors), input voltage range, and any necessary communication settings.

Maintenance suggestions: Regularly inspect the physical connections of the IOP345 to ensure that the cables are not loose or damaged. Check for any signs of overheating or abnormal operation, such as unusual noises or indicator lights. Periodically, use the diagnostic tools provided by Metso or the control system to perform self – tests on the module. These tests can detect any potential faults in the input channels, communication interfaces, or internal circuitry. If a fault is detected, refer to the module’s troubleshooting guide or contact Metso’s technical support for assistance. Keep the module’s enclosure clean and free from dust and debris, as these can affect the module’s performance over time. Replace any worn – out or damaged components, such as cables or connectors, promptly to ensure continued reliable operation.

Service and guarantee commitment

Metso provides a standard warranty for the IOP345, covering defects in materials and workmanship. The exact duration of the warranty can be obtained from Metso’s official documentation or by contacting their sales or support teams. In case of any issues during the warranty period, Metso’s technical support will assist in diagnosing and resolving the problem. They can provide remote support, such as software configuration assistance or troubleshooting over the phone or via online communication tools.

For out – of – warranty repairs, Metso offers repair services through their authorized service centers. These centers have trained technicians who are familiar with Metso products and can perform repairs to restore the IOP345 to its original working condition. Metso also provides access to spare parts through their online spare parts catalog, making it easier for customers to replace any damaged components on their own if they have the necessary technical skills. Additionally, Metso offers training programs on the installation, operation, and maintenance of the IOP345 for customers who want to enhance their in – house technical capabilities.