Description

D691-Z2708G: Product Overview

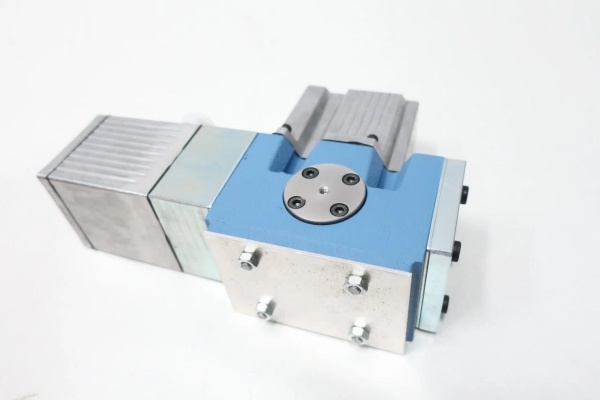

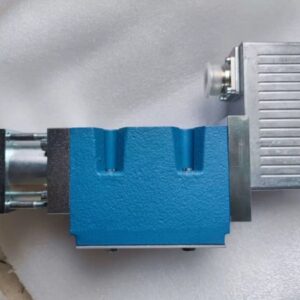

The MOOG D691-Z2708G is a two-stage electrohydraulic servo valve from the D691 Series, designed for precision control of hydraulic actuators in industrial applications requiring high stability and dynamic performance. As part of MOOG’s flagship line of electrohydraulic components, this valve integrates advanced hydraulic amplification technology to deliver accurate flow and pressure regulation, making it ideal for systems where precise actuator positioning, velocity control, or force modulation is critical.

The D691 Series is distinguished by its two-stage architecture: a nozzle-flapper pilot stage for signal amplification and a sliding spool main stage for flow modulation. This design ensures stable output even under varying load conditions, a key advantage over direct-drive valves in applications with fluctuating pressures or forces. The D691-Z2708G is typically deployed in closed-loop control systems (e.g., with position/force feedback sensors) to maintain desired actuator behavior, minimizing overshoot and ensuring consistent performance in machinery such as injection molding machines, metal forming presses, and material testing rigs.

MOOG D691-Z2708G

D691-Z2708G: Key Features & Customer Value

-

Two-Stage Design for Stability: The combination of a nozzle-flapper pilot stage and sliding spool main stage delivers stable flow output proportional to the input signal, even when system pressures fluctuate. This stability reduces actuator drift and ensures consistent part quality in manufacturing processes.

-

Fast Dynamic Response: With a step response time of <20 ms (from 0 to 90% flow), the valve quickly adjusts to changes in command signals, improving cycle time predictability in high-speed machinery.

-

High Resolution: The valve offers a resolution of <0.2% of full scale (hysteresis <0.7%), enabling precise control of small actuator movements—critical for applications like precision assembly or material testing.

-

Rugged Construction: Built with a stainless steel body and hardened spool lands, the D691-Z2708G resists wear from contaminated hydraulic fluids, extending service life to 10,000–15,000 operating hours (with proper filtration).

-

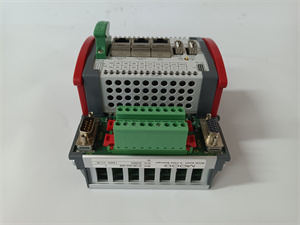

Flexible Integration: Native compatibility with standard analog controllers (PLCs, PID loops) and optional amplifiers simplifies integration, eliminating the need for custom signal conversion hardware. Field-replaceable spool/sleeve assemblies minimize downtime during maintenance.

MOOG D691-Z2708G

D691-Z2708G: Typical Applications

The D691-Z2708G is suited for industrial systems requiring precise hydraulic control:

-

Injection Molding Machines: Controls mold clamping cylinders for accurate part ejection and repeatability.

-

Metal Forming Presses: Regulates ram positioning in small stamping or bending machines to ensure tight tolerances.

-

Material Testing Rigs: Manages actuator movement in tensile/compression tests, delivering accurate cyclic loading profiles.

-

Robotic Systems: Provides precise motion control for robotic arms or end-effectors in assembly lines.