Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola FLN4234A |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Industrial Communication Expansion Module (Ethernet + serial multi-port extension) |

| Network Interfaces | 4x 10/100Base-T Ethernet ports (RJ45 connectors; IEEE 802.3 compliant); 8x RS-232/422/485 serial ports (DB9 connectors, software-selectable per port) |

| Bus Standard | VMEbus (PICMG VME 3.0 compliant) – 32-bit address/data bus; slave-only mode (controlled by VME SBC); supports VMEbus interrupts (level 1–7) |

| Communication Protocols | Ethernet: TCP/IP, UDP, ICMP, Modbus TCP; Serial: Modbus RTU, ASCII, RS-485 multi-drop (up to 32 nodes per port) |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.5 A typical, 2.0 A maximum); +12 VDC (0.4 A typical); -12 VDC (0.3 A typical); passive heat dissipation (heatsink-based, no fan) |

| Operating Temperature Range | -20°C – 70°C (-4°F – 158°F) (industrial-grade environmental tolerance for harsh sites) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 3.0; IEEE 802.3 (Ethernet); FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility) |

| Compatibility | Optimized for Motorola VME SBCs (MVME5500, MVME2434, MVME172-263/260); works with power modules (FAB 0340-1049, 01-W3324F)、I/O modules (MVME162-223, MVME172PA-652SE) |

| On-Board Features | Per-port status LEDs (Ethernet: link/activity; Serial: transmit/receive/error); built-in Ethernet switch (for daisy-chaining devices); serial port surge protection (2 kV ESD); firmware upgradable via VMEbus |

| Memory Configuration | 64 KB SRAM (for data buffering); 128 KB EEPROM (for protocol firmware and configuration storage) |

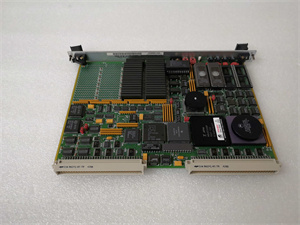

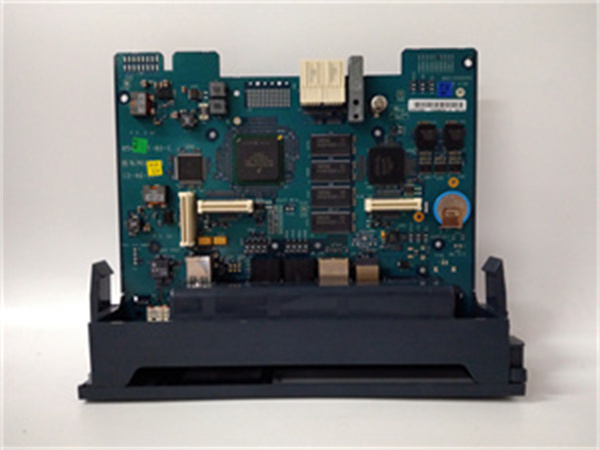

MOTOROLA FLN4234A

Product Introduction

The Motorola FLN4234A is a high-density VMEbus communication expansion module, engineered to address the multi-port connectivity needs of industrial automation systems—serving as a “communication hub” for VMEbus-based setups that require simultaneous Ethernet and serial data transmission. Unlike single-interface modules (e.g., MVME712/M with 2x Ethernet + 2x serial), the FLN4234A integrates 4x Ethernet ports and 8x serial ports, eliminating the need for multiple communication modules and saving VME chassis slots.

A defining strength of the FLN4234A is its seamless integration with the Motorola VME ecosystem. When paired with a host SBC like the MVME5500, it leverages the VMEbus to receive configuration commands (e.g., IP address setting, serial baud rate adjustment) and transmit high-volume data—such as real-time sensor readings from MVME172PA-652SE analog modules or discrete I/O states from MVME162-223 digital modules. It draws stable power from modules like the FAB 0340-1049 (via VME backplane) or 01-W3324F (for auxiliary power), while its -20°C–70°C temperature range ensures reliability in extreme environments—from cold warehouse control cabinets to hot factory floors.

Whether deployed in multi-device manufacturing lines、remote SCADA systems, or complex test benches, the FLN4234A enables centralized communication management. Its built-in Ethernet switch supports daisy-chaining of up to 4 downstream devices (e.g., HMIs, other VME chassis), while serial port surge protection safeguards against electrical interference—critical for industrial sites with frequent power fluctuations. These features make it an indispensable component for legacy VME systems requiring scalable, multi-protocol connectivity.

Core Advantages and Technical Highlights

High-Density Multi-Interface Design for Scalable Connectivity

The FLN4234A’s 4x Ethernet + 8x serial port configuration eliminates the need for 3–4 single-interface modules, reducing VME chassis slot usage by up to 75%. For example, in an automotive assembly line with 6x MVME162-223 digital modules (controlling robotic arms) and 4x HMIs, the FLN4234A can: 1) connect 4 HMIs via Ethernet (1 port per HMI), 2) link 6 serial ports to the MVME162-223 modules (for local control), and 3) use the remaining 2 serial ports for barcode scanners. This centralized layout simplifies wiring and reduces communication latency—critical for real-time coordination of multi-device workflows.

Built-In Ethernet Switch for Daisy-Chaining Flexibility

Unlike modules that require external switches, the FLN4234A integrates a 4-port Ethernet switch, enabling daisy-chaining of downstream devices (e.g., other VME chassis, remote I/O racks) without additional hardware. For instance, in a food processing plant with 3 distributed VME control cabinets (each with a MVME5500), the FLN4234A in the master cabinet can connect to the other two cabinets via Ethernet (1 port per cabinet), while the remaining 2 ports link to a central SCADA server and HMI. This reduces Ethernet cable runs by 50% compared to star-topology setups, lowering installation costs and simplifying maintenance.

Serial Port Surge Protection and EMC Immunity

The FLN4234A’s serial ports feature 2 kV ESD surge protection—double the protection of standard modules like the MVME712/M—safeguarding against electrical interference from nearby motors, welders, or power tools. In a steel mill, for example, where EMI is prevalent, this protection ensures serial communication with MVME162-223 modules (controlling conveyor motors) remains stable, avoiding data loss or incorrect I/O commands. The module’s compliance with IEC 61000-6-4 further enhances EMC immunity, making it suitable for heavy-industry environments.

Seamless VME Ecosystem Compatibility

The FLN4234A is engineered to work with Motorola’s core VME components: it automatically recognizes host SBCs like the MVME5500 via the VMEbus, allowing the SBC to configure communication parameters (e.g., Ethernet IP, serial parity) without manual intervention. It also supports Modbus TCP/RTU—compatible with thousands of industrial devices (e.g., sensors, actuators) that use this protocol—enabling integration with both legacy and modern systems. For example, the FLN4234A can transmit MVME172PA-652SE analog data (via Modbus TCP) to a new cloud platform, while sending discrete I/O states (via Modbus RTU) to a legacy HMI—avoiding the need for a complete system overhaul.

Typical Application Scenarios

Multi-Line Manufacturing Control

In a electronics manufacturing facility with 4 production lines, the FLN4234A (installed in a central VME chassis with MVME2434 SBC) acts as a communication hub: 4x Ethernet ports connect to line-specific HMIs (for operator control), 6x serial ports link to MVME162-223 digital modules (monitoring component placement sensors), and 2x serial ports connect to barcode scanners (tracking work-in-progress). The built-in Ethernet switch daisy-chains the 4 HMIs, reducing cable runs from 16 to 4. The module’s passive cooling design withstands the facility’s 65°C ambient temperature, while surge protection prevents damage from welding-induced EMI.

Remote SCADA for Oil Pipelines

In a 500km oil pipeline monitoring system, the FLN4234A is installed in each remote monitoring station (paired with MVME172-263/260 SBC): 1x Ethernet port connects to a 4G router (transmitting data to a central SCADA system), 2x serial ports link to MVME172PA-652SE analog modules (monitoring pipeline pressure/temperature), and 5x serial ports connect to valve controllers (for remote flow adjustment). The module’s -20°C–70°C range withstands the station’s extreme day-night temperature swings (-15°C to 60°C), while its serial port buffering (64 KB SRAM) prevents data loss during temporary 4G signal drops—critical for maintaining pipeline safety.

Complex Test Benches for Aerospace

In an aerospace engine test bench, the FLN4234A (paired with MVME5500 SBC) coordinates multi-instrument communication: 2x Ethernet ports connect to high-speed data loggers (capturing test results), 3x serial ports link to MVME172PA-652SE modules (measuring engine vibration/fuel pressure), and 5x serial ports connect to calibration tools (for real-time sensor adjustment). The module’s firmware upgradability allows adding custom protocols (e.g., ARINC 429 for avionics) via VMEbus, while its EMC immunity ensures accurate data capture in the test chamber’s high-noise environment—meeting aerospace testing standards (e.g., DO-160).

MOTOROLA FLN4234A

Related Model Recommendations

Motorola MVME5500: VME SBC. Host controller for FLN4234A; configures the module’s ports, processes communication data, and executes control logic—critical for leveraging multi-interface connectivity.

Motorola FAB 0340-1049: Power supply module. Primary power source for FLN4234A; delivers stable +5 VDC (2.0 A max) and ±12 VDC to support the module’s Ethernet/serial circuits.

Motorola 01-W3324F: Power distribution terminal block. Supplies auxiliary power to FLN4234A (if VME backplane power is insufficient) and distributes 24V DC to connected sensors/actuators.

Motorola MVME162-223: Digital I/O module. Key data source for FLN4234A; transmits discrete I/O states to the module for remote monitoring via Ethernet/serial.

Emerson FLN4234B: Modern communication module. Successor to FLN4234A with Gigabit Ethernet (1000Base-T) and 16x serial ports; ideal for users needing higher bandwidth.

Phoenix Contact FL SWITCH SFN 8TX: Industrial Ethernet switch. Complements FLN4234A in large systems (10+ devices); expands Ethernet ports to 8 for additional downstream HMIs or I/O racks.

Motorola MVME712/M: Compact communication module. Alternative for small systems (2–3 devices); 2x Ethernet + 2x serial ports for cost-sensitive applications where high density is unnecessary.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing FLN4234A, power off the VME chassis and disconnect the FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 32-bit slave modules. Use an anti-static wristband and mat to protect the module’s Ethernet/serial components from ESD damage. Gather tools: Phillips-head screwdriver (for chassis mounting), Cat5e/Cat6 Ethernet cables (for network connections), DB9 serial cables (for device links), and a torque wrench (to tighten chassis screws to 1.0–1.2 N·m). Avoid installing near high-voltage equipment (e.g., transformers) or heat sources (e.g., power resistors) to prevent EMI or thermal throttling.

Commissioning and Maintenance

For commissioning, insert the FLN4234A into the VME slot and secure it. Power on the FAB 0340-1049 and 01-W3324F (if used), then check the module’s LEDs: green “POWER” confirms voltage; Ethernet “LINK” LEDs (solid green) indicate network connections; serial “TX/RX” LEDs (blinking) signal data transmission. Use the MVME5500’s configuration software (e.g., Emerson’s VME Config Tool) to set Ethernet IP addresses (for each port) and serial parameters (baud rate, parity, stop bits) per port. Test connectivity by pinging each Ethernet port from a SCADA workstation and sending test signals via serial ports to connected devices (e.g., MVME162-223).

For maintenance: Inspect Ethernet/serial cables monthly—tighten connectors to prevent intermittent connections and replace damaged cables. Clean the module quarterly with compressed air (low pressure) to remove dust from the heatsink and VME connector (avoids overheating). Update the module’s firmware annually (via VMEbus) using Emerson’s legacy firmware tools—this addresses protocol bugs and improves compatibility with modern SCADA systems. If a serial port fails, use the MVME5500’s diagnostic tools to isolate the issue (e.g., ESD damage) and reconfigure a spare port as a replacement. When upgrading, replicate the old unit’s port configuration to avoid disrupting system communication.

Service and Guarantee Commitment

Though Motorola FLN4234A is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in Ethernet/serial port functionality, LED indicators, and surge protection. Each refurbished module undergoes rigorous testing: 24-hour Ethernet data transfer testing (verifying 100 Mbps speed and zero packet loss), serial protocol validation (Modbus RTU/TCP compatibility), and ESD surge testing (ensuring 2 kV protection). This guarantees the module meets the original industrial-grade communication standards.

Our technical support team (24/7 availability) provides guidance on FLN4234A installation、protocol configuration, and integration with VME SBCs like the MVME5500 or MVME2434. We offer customized maintenance plans: quarterly remote network health checks (via Ethernet) and semi-annual on-site inspections (cleaning ports, testing surge protection). Our spare parts inventory includes critical components (e.g., Ethernet transceivers, serial port protectors) for fast repairs—minimizing communication downtime.

For users modernizing to Ethernet-based systems, we provide free consultation to select Emerson’s RSTi-EP communication modules (e.g., FLN4234B) that retain the FLN4234A’s multi-interface functionality while adding Gigabit Ethernet and cybersecurity features. We also offer trade-in credits for old units, reducing the cost of upgrading to more secure, high-bandwidth connectivity solutions. Our commitment to legacy support ensures your VME system’s communication backbone remains reliable, whether you maintain existing infrastructure or transition to new platforms.