Description

Product Introduction

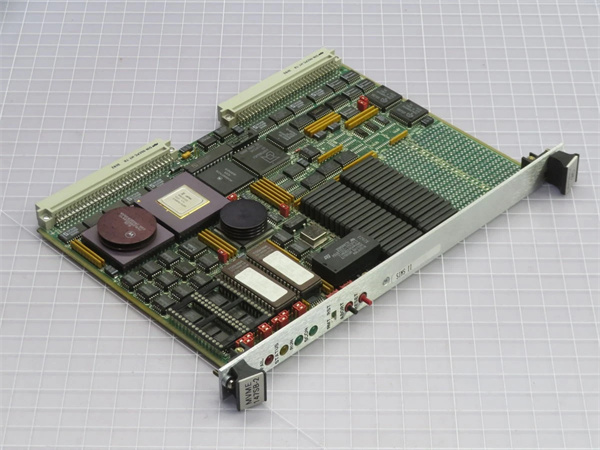

The Motorola MVME – 147SB – 2 is a high – performance single – board computer (SBC) designed for industrial and embedded applications. It is part of the MVME – 147 series, which is renowned for its reliability and versatility in demanding environments. This particular model, the MVME – 147SB – 2, offers enhanced features and capabilities that make it a suitable choice for a wide range of industrial control, data acquisition, and communication tasks.

Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME – 147SB – 2 |

| Manufacturer | Motorola (now under Emerson Industrial Automation) |

| Product Category | VMEbus Single – Board Computer |

| Processor | 33 MHz MC68030 enhanced 32 – bit microprocessorOptional: 33.33 MHz MC6888 co – processor |

| Memory | 16 MB DRAM512 KB SRAM with battery backup1 MB flash memory for on – board monitor/debugger or user – installed firmware8 k x 8 NVRAM and time – of – day clock with battery backup |

| Communication Interfaces | Two serial communication ports (console port as EIA – 232 – D DTE and second port user – configurable for EIA – 232 – D/EIA – 422 (V.36) DTE/DCE)Optional: SCSI bus interface with 32 – bit local bus burst DMAOptional: Ethernet transceiver interface with 32 – bit local bus DMA |

| Expansion Ports | Four 16 – or 32 – bit Industry Pack® ports with one DMA channel per port |

| Timers | Six 32 – bit timers (four without VMEbus) and watchdog timer |

| VMEbus Interface | A32/D64 VMEbus master/slave interface with system controller functionHigh – performance DMA support for VMEbus D64 and local bus memory burst cycles |

| Interrupt System | Four – level requester, seven – level interrupter, and seven – level interrupt handler for VMEbus |

| Other Features | Remote reset/abort/status control functionsOn – board debugger and diagnostic firmware |

| Physical Dimensions | Dimensions suitable for VMEbus form factor (standard VMEbus board size to fit in common chassis) |

| Power Requirements | Power consumption details to be specified based on the actual configuration (varies with processor and additional interfaces in use) |

| Operating Temperature | Operating Temp: – 40°C – 85°C (- 40°F – 185°F) |

| Storage Temperature | Storage Temp: – 55°C – 125°C (- 67°F – 257°F) |

| Humidity | Humidity: 5% – 95% non – condensing |

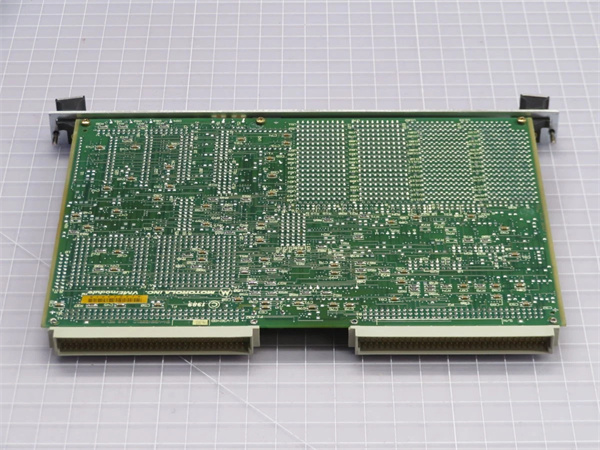

Motorola MVME-147SB-2

Core Advantages and Technical Highlights

Powerful Processor Performance: The 33 MHz MC68030 enhanced 32 – bit microprocessor, with the option of a 33.33 MHz MC6888 co – processor, provides high – speed processing capabilities. The MC68030 was the first general – purpose microprocessor with on – chip cache memory for both instructions and data. This cache memory significantly increases the processor’s efficiency by 20 to 40 percent. Additionally, it features a complete memory management unit (MMU), which offers software protection and virtual memory functions crucial for many industrial applications. For example, in a complex industrial control system where multiple tasks need to be executed simultaneously, the powerful processor can handle real – time data processing, control algorithms, and communication protocols without significant latency.

Rich Memory Configuration: With 16 MB of DRAM, the MVME – 147SB – 2 can store and process large amounts of data. The 512 KB SRAM with battery backup ensures that critical data is retained even during power outages. The 1 MB flash memory is used for on – board monitor/debugger or can be utilized for user – installed firmware. The 8 k x 8 NVRAM, along with the time – of – day clock with battery backup, provides a reliable way to store configuration data and keep track of time – sensitive operations. In a data – logging application in an industrial plant, the ample memory can buffer large volumes of sensor data before it is transferred to a more permanent storage medium.

Versatile Communication Interfaces: The two serial communication ports, with one configurable for different standards (EIA – 232 – D/EIA – 422), make it easy to interface with a variety of serial devices. The optional SCSI bus interface, with 32 – bit local bus burst DMA, enables high – speed data transfer to and from storage devices such as hard drives or tape drives. The optional Ethernet transceiver interface, also with 32 – bit local bus DMA, allows for seamless integration into networked environments, facilitating remote monitoring and control. In a factory automation setting, the MVME – 147SB – 2 can communicate with legacy serial – based sensors and actuators using the serial ports, while also being able to send data over the network to a central control station via the Ethernet interface.

Flexible Expansion Options: The four 16 – or 32 – bit Industry Pack® ports, each with its own DMA channel, provide a convenient way to expand the functionality of the board. These ports can be used to connect additional I/O modules, communication interfaces, or specialized processing units. For instance, in a manufacturing process control system, an Industry Pack® module for analog – to – digital conversion can be added to the MVME – 147SB – 2 to interface with analog sensors, enhancing the system’s ability to monitor and control analog signals.

Typical Application Scenarios

Industrial Process Control: In a chemical manufacturing plant, the MVME – 147SB – 2 can be used as the central controller. It can receive data from various sensors (such as temperature, pressure, and flow sensors) through its serial ports or analog – to – digital conversion modules connected via the Industry Pack® ports. Based on this data, it can execute control algorithms to adjust the operation of pumps, valves, and other actuators. The Ethernet interface can be used to send real – time process data to a plant – wide monitoring system, allowing operators to remotely monitor and manage the production process. The on – board debugger and diagnostic firmware are valuable for troubleshooting any issues that may arise during the operation of the control system.

Data Acquisition and Monitoring in Power Plants: In a power generation facility, the MVME – 147SB – 2 can be deployed to acquire data from a large number of sensors distributed across the plant. These sensors may measure parameters such as voltage, current, frequency, and vibration. The SCSI bus interface can be used to connect high – capacity storage devices to store the acquired data for later analysis. The serial ports can be used to communicate with intelligent sensors or other devices that use serial communication protocols. The MVME – 147SB – 2’s ability to handle multiple tasks simultaneously and its reliable performance in harsh environments (with an operating temperature range of – 40°C – 85°C) make it suitable for continuous operation in a power plant.

Automated Test Equipment: In an electronics manufacturing factory, the MVME – 147SB – 2 can be integrated into automated test equipment. It can control the test process, communicate with test instruments (such as oscilloscopes, multimeters, and logic analyzers) via serial or Ethernet interfaces, and analyze the test results. The Industry Pack® ports can be used to connect custom – designed I/O modules for specific test requirements. For example, a module for generating and measuring high – speed digital signals can be added to test the performance of digital integrated circuits. The remote reset/abort/status control functions are useful for remotely controlling the test equipment and monitoring its status.

Compatibility with MVME – 332XT

The Motorola MVME – 147SB – 2 pairs extremely well with the MVME – 332XT. The MVME – 332XT, with its 8 – channel serial control and parallel printer port, can be connected to the MVME – 147SB – 2 via the serial ports. In an industrial printing and monitoring application, such as in a food packaging plant, the MVME – 332XT can collect data from serial – based sensors (like package presence sensors and weight scales) and send this data to the MVME – 147SB – 2 for further processing. The MVME – 147SB – 2 can then analyze the data, generate reports, and send the print commands to the parallel printer connected to the MVME – 332XT. The MVME – 147SB – 2’s powerful processing capabilities can handle the data from multiple MVME – 332XT units if needed, making it an ideal host for a network of serial – controlled devices.

Motorola MVME-147SB-2

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Before installing the MVME – 147SB – 2, ensure that the VMEbus chassis has an appropriate slot available. The slot should be able to support the A32/D64 VMEbus interface of the board.

Check the power supply to ensure it can provide the required voltage levels (details of which vary depending on the actual configuration of the board). Use a multimeter to verify the stability of the power supply and avoid voltage ripple that could affect the performance of the board.

Gather necessary tools such as an anti – static wristband to protect sensitive components during installation. A torque screwdriver may be required to properly secure the board in the chassis.

If adding optional modules (such as the SCSI or Ethernet modules), ensure that they are properly configured and compatible with the MVME – 147SB – 2.

Commissioning:

After installation, power on the system. The on – board debugger and diagnostic firmware will perform self – tests. Check the status LEDs on the board to ensure that there are no error indications.

Configure the serial ports, SCSI interface (if installed), and Ethernet interface (if installed) according to the requirements of the application. This may involve setting baud rates, IP addresses, and other communication parameters.

Test the communication interfaces by connecting to a known device (such as a serial terminal for the serial ports, a storage device for the SCSI interface, or a network switch for the Ethernet interface) and verifying data transfer.

Maintenance Suggestions:

Regularly check the status of the board using the on – board diagnostic tools. Monitor the system logs for any error messages.

If the board is used in a dusty environment, clean it periodically (using compressed air at an appropriate pressure) to prevent dust accumulation, which could affect the performance of the components.

Check the battery backup for the SRAM and NVRAM periodically to ensure that critical data is not lost during power outages. Replace the battery when its voltage drops below the recommended level.

If there are any issues with the communication interfaces, check the cables for damage and verify the configuration settings.

Service and Guarantee Commitment

The Motorola MVME – 147SB – 2, like other products in the MVME series, may come with a standard warranty period from Emerson (which now owns the Motorola industrial automation product line). The warranty typically covers manufacturing defects in the processor, memory, and other components. In case of any hardware failures within the warranty period, Emerson provides repair or replacement services. For extended service, customers can purchase service contracts that may include remote technical support, software updates (if applicable), and on – site maintenance. Emerson also maintains a stock of replacement parts for the MVME – 147SB – 2, ensuring that customers can keep their systems operational for an extended period. This commitment to service and support is crucial for industrial customers who rely on the continuous operation of their embedded systems.