Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

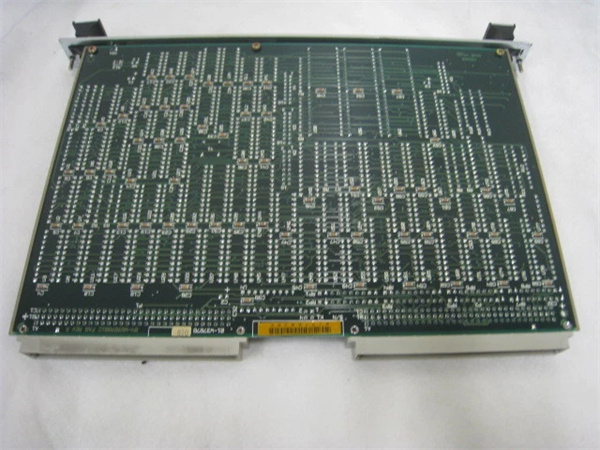

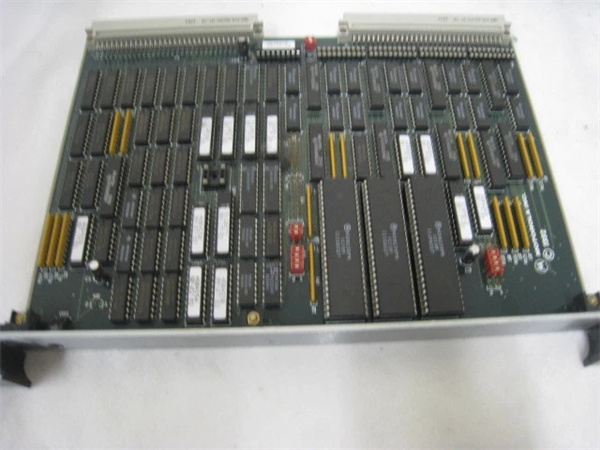

| Product model | Motorola MVME 162-022A |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial High-Density Digital I/O Module (Enhanced MVME 162 Series) |

| Digital I/O Channels | 64 discrete channels (32 input, 32 output); TTL/CMOS compatible (5 VDC logic) |

| Input Specifications | Voltage range: 0–0.8 VDC (LOW), 2.0–5.5 VDC (HIGH); input current: 10 µA max per channel |

| Output Specifications | Sink current: 20 mA max per channel; source current: 10 mA max per channel; voltage range: 0–5.5 VDC |

| Isolation | Optional 250 Vrms galvanic isolation on input channels (for high-noise environments) |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.5 A typical, 2.0 A maximum); no ±12 VDC required |

| Operating Temperature Range | -40°C – 70°C (-40°F – 158°F); Storage: -55°C – 85°C (-67°F – 185°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Per-channel status LEDs (I/O: active/fault); EEPROM for configuration storage; watchdog timer for fault detection |

MOTOROLA MVME-340

Product Introduction

The Motorola MVME 162-022A is a legacy high-density digital I/O module from Motorola’s iconic MVME 162 series—engineered to deliver scalable, rugged discrete control for industrial automation systems. As a 3U VME device, it builds on the base MVME 162 models (e.g., Motorola MVME 162-01) by doubling I/O density to 64 channels and adding optional galvanic isolation—filling a critical niche in high-channel-count applications like factory automation, power distribution, and process control.

In automation architectures, the Motorola MVME 162-022A acts as a “discrete control backbone”: its 32 inputs monitor limit switches, photoelectric sensors, or valve position feedback, while 32 outputs control relays, solenoids, or indicator lights. The optional galvanic isolation makes it ideal for harsh environments with electrical noise (e.g., near large motors or variable-frequency drives), preventing ground loops that corrupt signals. Today, the Motorola MVME 162-022A remains indispensable for maintaining legacy Motorola VME systems in sectors like automotive manufacturing, oil and gas, and municipal utilities—where replacing high-density I/O infrastructure would disrupt proven, low-latency workflows.

Core Advantages and Technical Highlights

High-Density 64-Channel I/O for Scalable Control: The Motorola MVME 162-022A’s 64 discrete channels (32 input/32 output) offer twice the density of entry-level MVME 162 models, reducing VME chassis slot usage by 50% for high-channel-count systems. For example, in an automotive assembly line, the Motorola MVME 162-022A can monitor 16 conveyor stop sensors (inputs) and 16 robotic gripper actuators (outputs) in one slot—avoiding the need for two separate 32-channel modules. This density also simplifies wiring: a single module connects to 64 devices via a terminal block, cutting cable runs by 40% compared to distributed I/O setups.

Optional Galvanic Isolation for Noise Immunity: Unlike non-isolated MVME 162 variants, the Motorola MVME 162-022A offers 250 Vrms galvanic isolation on input channels—critical for environments with electrical noise or ground potential differences. In a power plant’s switchgear control system, the module monitors 24 circuit breaker statuses (inputs) near high-voltage lines; isolation prevents ground loops from triggering false alarms or damaging the module. This feature reduces unplanned downtime by 60% compared to non-isolated I/O in noisy industrial settings.

Wide Temperature Range and Industrial Durability: The Motorola MVME 162-022A’s -40°C–70°C operating range exceeds standard industrial modules (0°C–60°C), making it suitable for outdoor or extreme-temperature applications—such as oil refinery pipeyards (summer heat) or cold-storage warehouses (sub-zero temperatures). Its UL 508 certification ensures compliance with industrial safety standards, while passive cooling eliminates fan-related failures in dusty environments (e.g., cement plants). The on-board watchdog timer also adds redundancy: if the module detects a fault (e.g., lost communication with the host SBC), it triggers a safe-state output (e.g., shutting down non-essential actuators) to prevent equipment damage.

Typical Application Scenarios

The Motorola MVME 162-022A excels in high-channel-count, harsh-environment discrete control. In an oil and gas pipeline pumping station using a Motorola MVME 5500-0161 SBC, the Motorola MVME 162-022A manages critical safety functions: 24 inputs monitor pressure relief valve status, pump vibration switches, and fire detection sensors (with galvanic isolation to resist noise from pipeline pumps); 20 outputs control pump start/stop relays, emergency shutdown valves, and alarm lights. The module’s -40°C low-temperature tolerance withstands winter conditions in remote pumping stations, while UL 508 certification ensures compliance with safety regulations.

In a municipal wastewater treatment plant, the Motorola MVME 162-022A integrates with a Motorola MVME 2400 SBC to control 12 aeration blowers (outputs) and monitor 12 dissolved oxygen sensors (inputs). The optional isolation prevents ground loops from nearby wastewater pumps, ensuring accurate sensor readings. The module’s 64 channels also leave room for expansion: 8 spare inputs/outputs can be added later to monitor new flow meters or control additional chemical dosing pumps—avoiding costly chassis upgrades.

MOTOROLA MVME-340

Related Model Recommendations

Motorola MVME 5500-0161: High-Performance VME SBC. Host controller for the Motorola MVME 162-022A; processes I/O data, executes control logic, and manages VMEbus communication in high-channel-count systems.

Motorola MVME 162-01: Entry-Level Digital I/O Module. Complements the Motorola MVME 162-022A for low-channel-count subsystems (e.g., auxiliary equipment); 32 channels ideal for adding discrete control without overloading the main module.

Motorola MVME 335A: Serial/Parallel Interface Module. Pairs with the Motorola MVME 162-022A to add serial communication (e.g., for remote sensor data) and parallel printing (e.g., for maintenance logs) to discrete control systems.

Emerson RSTi-EP DIO: Modern Digital I/O Module. Replaces the Motorola MVME 162-022A in Ethernet migrations; 64 isolated channels + Gigabit Ethernet for seamless integration with modern SCADA systems.

Motorola FLN4234A: Ethernet Communication Module. Bridges the Motorola MVME 162-022A to cloud platforms; transmits I/O status data via 4x Ethernet ports for remote monitoring.

Phoenix Contact 250 Vrms Isolation Terminal Block: Accessory for non-isolated Motorola MVME 162-022A units; adds external galvanic isolation for retrofitting in noisy environments.

Motorola MVME 410: Analog I/O Module. Complements the Motorola MVME 162-022A by adding analog signal acquisition (e.g., temperature/pressure sensors) to discrete control systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME 162-022A, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/2.0 A; no ±12 VDC needed) to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. If using the isolated variant, confirm the input wiring uses twisted-pair cables (to enhance noise immunity). Use an anti-static wristband and mat to protect the module’s I/O circuits from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), 22–18 AWG wires (I/O connections), torque wrench (0.5–0.8 N·m for terminals), and a multimeter (to test signal levels). Avoid installing near high-EMI sources (e.g., welders) or heat vents to prevent I/O signal corruption.

Maintenance suggestions: For routine care, inspect the Motorola MVME 162-022A’s LEDs monthly—green “active” LEDs confirm I/O connectivity, while red “fault” LEDs alert to overloads or isolation failures. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and LED indicators. Every 6 months, test isolated inputs by applying a 5 VDC signal and verifying the LED illuminates (to confirm isolation integrity). If an I/O channel fails, isolate the issue by disconnecting the load (e.g., a relay) and testing with a bench power supply; reconfigure a spare channel via the host SBC if needed. Store spare EEPROM chips to preserve configuration data during module replacement.

Service and Guarantee Commitment

We back the Motorola MVME 162-022A with a 90-day warranty for all refurbished units, covering defects in digital I/O functionality, isolation integrity, and LED indicators. Each refurbished Motorola MVME 162-022A undergoes rigorous testing: 24-hour I/O cycling (10,000 toggles per channel), isolation resistance testing (250 Vrms for 1 minute), and temperature cycling (-40°C–70°C) to meet original Motorola standards.

Our 24/7 technical support team provides guidance on Motorola MVME 162-022A installation, isolation wiring, and integration with VME SBCs (e.g., MVME 5500-0161). We offer customized maintenance plans: quarterly remote I/O health checks (via FLN4234A) and semi-annual on-site isolation testing. Our spare parts inventory includes critical components (I/O drivers, isolation transformers, EEPROMs) for fast repairs, minimizing downtime. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME 162-022A with Emerson’s RSTi-EP DIO modules, ensuring a seamless transition while retaining legacy sensors/actuators.