Description

Detailed Parameter Table

| Parameter name | Parameter value |

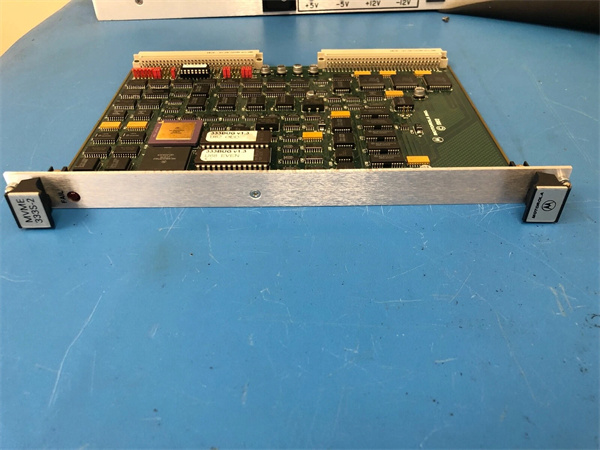

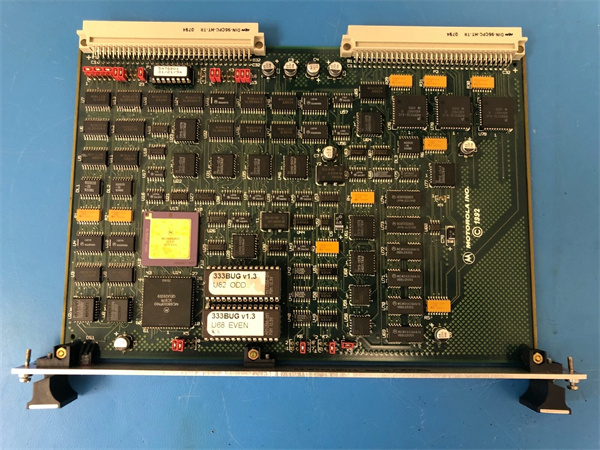

| Product model | Motorola MVME-162-531 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Entry-Level Real-Time Single-Board Computer (SBC) |

| Processor | 25 MHz Motorola MC68030 32-bit microprocessor; 2 KB L1 cache, Basic MMU (Memory Management Unit); No FPU (Floating-Point Unit) |

| Memory Configuration | 4 MB shared DRAM (no parity); 128 KB battery-backed SRAM (non-volatile); 256 KB EPROM (firmware only, no debugger support) |

| Communication Interfaces | 1x serial port (EIA-232-D DTE console only); No user-configurable serial ports; No Ethernet support |

| Expansion Interfaces | 1x 8-bit Industry Pack® port (no DMA); VMEbus A16/D16 master/slave (IEEE 1014-1987 compliant, limited address range) |

| Environmental Ratings | Operating temperature: 5°C–55°C (41°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 15%–85% (non-condensing); Vibration: 10–1000 Hz, 0.8 g (rms); Shock: 30 g (peak, 1 ms) |

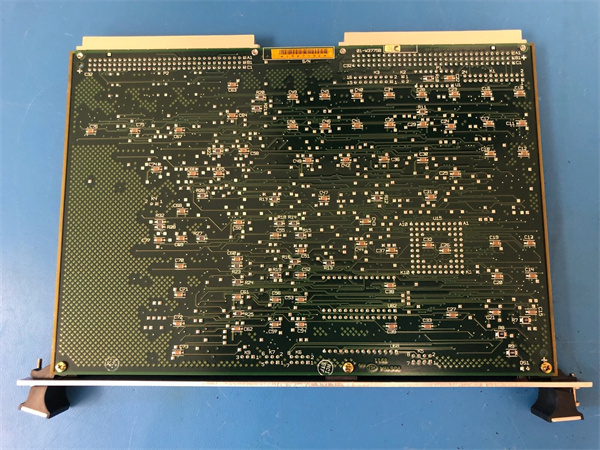

| Physical Dimensions | Double-high 6U VME form factor: 233.4mm × 160mm × 28mm (9.19in × 6.30in × 1.10in); Weight: 720 g (1.59 lbs) |

| Power Consumption | Typical: 12 W (25°C, no Industry Pack module); Maximum: 18 W (Industry Pack port active) |

| Diagnostic Features | Single LED indicator (power/processor activity combo); No DRAM status monitoring; Basic VMEbus error detection (no interrupt handler) |

| Compatible Peripherals | Motorola IP-200 (8-bit digital I/O Industry Pack), Motorola MVME-340A (legacy serial module), Motorola MVME-177-001 (basic analog input) |

| Operating System Support | OS-9 v2.0, VxWorks 5.0 (simplified kernel), QNX 4.20; Supports basic multi-tasking (up to 16 concurrent tasks) |

| Product Life Cycle | Discontinued/Obsolete (1980s–1990s production) |

Motorola MVME-333S-2

Product Introduction

The Motorola MVME-162-531 is a legacy industrial VMEbus entry-level real-time SBC designed to deliver basic processing functionality for 1980s–1990s low-complexity automation tasks—serving as the predecessor to the more capable Motorola MVME-162-532. Unlike its successor (which adds a second serial port, 16-bit Industry Pack support, and more memory), Motorola MVME-162-531 relies on a 25 MHz MC68030 processor and minimal expansion to meet the needs of simple control systems where advanced features are unnecessary.

As one of Motorola’s earliest VME entry-level SBCs, Motorola MVME-162-531 acted as a “foundational control node” for industrial setups. It connected to basic peripherals (e.g., Motorola IP-200 for digital I/O) via a single 8-bit Industry Pack port and communicated with local devices through its sole serial port. For example, in a 1980s small-scale assembly line, Motorola MVME-162-531 monitored a single “part present” sensor and activated a sorting solenoid—its battery-backed SRAM ensuring production counts were preserved during power outages. Today, it remains critical for vintage industrial systems (e.g., museum exhibits, legacy manufacturing equipment) where replacing it would require full retrofitting of 8-bit I/O infrastructure.

Core Advantages and Technical Highlights

Foundational Reliability for Vintage Systems: Motorola MVME-162-531’s simplified design (fewer components, basic firmware) makes it highly durable for long-term operation in stable environments—outperforming more complex SBCs that suffer from obsolescent advanced features. A museum preserving a 1985 automotive test rig uses Motorola MVME-162-531 to control a basic hydraulic pressure tester: the MC68030 processor reliably executes simple threshold checks (e.g., “stop test if pressure > 500 PSI”) after 30+ years of operation. Unlike newer SBCs, its lack of complex diagnostics or expansion ports means fewer points of failure, ensuring consistent performance for historical equipment.

Cost-Effective for Minimal I/O Needs: Motorola MVME-162-531 delivers essential processing at a fraction of the cost of mid-tier SBCs like Motorola MVME-162-532. A 1980s rural grain silo used Motorola MVME-162-531 to monitor a single level sensor (via Motorola IP-200) and send low-level alerts via its serial port to a local terminal. This setup avoided the $800+ premium for Motorola MVME-162-532’s unused features, while the 4 MB DRAM and 25 MHz processor still handled daily silo level logging without performance bottlenecks.

Low Power + Compact Design for Space-Constrained Setups: With 12 W typical power consumption (25% lower than Motorola MVME-162-532) and a slim 28mm profile, Motorola MVME-162-531 fits in compact 1980s-era VME chassis (e.g., 2-slot units) used in laboratory test equipment or standalone controllers. A 1988 environmental monitoring station used Motorola MVME-162-531 to log temperature data from a single sensor: its low power draw allowed the station to run on solar power for 12+ hours daily, while its lightweight design simplified mounting in small outdoor enclosures.

Typical Application Scenarios

In a 1980s small-scale electronics component tester, Motorola MVME-162-531 controlled a basic continuity testing circuit—paired with Motorola IP-200 (8-bit digital I/O) to activate test probes and read pass/fail signals. The MC68030 processor logged test results to its 128 KB SRAM and sent daily summaries to a vintage serial printer via its console port. Its 5°C–55°C operating range withstood the tester’s indoor 20°C–25°C environment, while the simplified design ensured no unplanned downtime during 8-hour production shifts. Motorola MVME-162-531’s reliability kept the tester operational for 15+ years, proving its value for single-function automation tasks.

For a 1989 municipal traffic light controller (small intersection with 2 directions), Motorola MVME-162-531 managed signal timing via Motorola IP-200 (digital outputs to light relays). It used its battery-backed SRAM to store 3 timing profiles (morning rush, midday, evening) and adjusted signals based on a simple internal clock—no external sensors or Ethernet connectivity needed. The SBC’s 30 g shock resistance handled occasional road vibrations, and its low power consumption (12 W) reduced the controller’s utility costs. Motorola MVME-162-531 remained in service until 2010, when the intersection was upgraded to a smart system—highlighting its longevity for low-complexity, critical infrastructure tasks.

Motorola MVME-333S-2

Related Model Recommendations

Motorola MVME-162-532: Successor model – Upgrade for Motorola MVME-162-531 users needing more memory (8 MB vs. 4 MB), a second serial port, or 16-bit Industry Pack support (e.g., adding analog sensors).

Motorola IP-200: 8-bit digital I/O Industry Pack – Pair with Motorola MVME-162-531 to add 8 discrete input/output channels for controlling relays, indicators, or simple sensors.

Motorola MVME-340A: Legacy serial module – Complements Motorola MVME-162-531 by adding a second RS-232 port (vs. MVME-162-531’s single port) for connecting extra serial devices like barcode scanners.

Motorola MVME-147-001: Ultra-entry-level SBC – Alternative for users with even simpler tasks (e.g., single-relay control) who don’t need Motorola MVME-162-531’s MC68030 performance.

Emerson MVME-162-531-R: Refurbished variant – Tested to original 8-bit I/O specs; Critical replacement for failing Motorola MVME-162-531 units in vintage systems (e.g., museum exhibits).

Motorola MVME-177-001: Basic analog input module – Expand Motorola MVME-162-531’s capabilities with 4-channel analog input (0–5V) for simple temperature or pressure monitoring.

Motorola 30GD-1-U4300099: Legacy industrial DC PSU – Powers Motorola MVME-162-531 with stable +5V DC (±5%), matching the SBC’s low power requirements (12 W typical).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-162-531, verify the VME chassis supports double-high 6U modules and A16/D16 addressing (critical for compatibility with its limited VMEbus range). Confirm the power supply (e.g., Motorola 30GD-1-U4300099) provides +5V DC (±5%) – use a precision multimeter to avoid voltage ripple (>100mV will cause DRAM errors, as there is no parity). Gather tools: anti-static wristband (protects the MC68030 processor), torque screwdriver (0.5 N·m for 6U mounting), and 8-bit Industry Pack alignment tool (to avoid damaging the single expansion port). Ensure connected Industry Pack modules are 8-bit (e.g., Motorola IP-200); 16-bit modules will not function with Motorola MVME-162-531.

Maintenance suggestions: For daily upkeep, check Motorola MVME-162-531’s single LED – steady light means power is active; blinking indicates processor activity (no separate error feedback). Test DRAM quarterly via the host OS (look for data corruption in stored logs, as there is no status monitoring); replace DRAM if errors occur. Clean the module’s vents semi-annually with compressed air (10 PSI max) – 1980s-era components are sensitive to dust buildup. Replace the SRAM battery every 2 years (3V lithium, vintage-style) during scheduled downtime. Store spare Motorola MVME-162-531 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the MC68030 and EPROM, which are no longer in production.

Service and Guarantee Commitment

Motorola MVME-162-531 is backed by a 12-month warranty from Emerson for refurbished units, covering defects in the MC68030 processor, DRAM, and 8-bit Industry Pack port. If Motorola MVME-162-531 fails (e.g., in a museum’s vintage test rig), Emerson provides free 10-day replacement – critical for users where no modern SBC can replicate its 8-bit I/O compatibility and vintage firmware support.

For extended support, customers can purchase a 24-month service contract, including specialized technical support for 1980s-era VME systems (via phone/email), access to archived OS images (e.g., OS-9 v2.0) and legacy driver packages, and remote troubleshooting for 8-bit Industry Pack integration. Emerson maintains a limited global stock of MC68030 chips and 4 MB DRAM modules for Motorola MVME-162-531 until 2035, ensuring this foundational SBC remains operational for vintage preservation and legacy industrial needs. This commitment underscores Emerson’s dedication to supporting even the earliest generations of industrial automation infrastructure.