Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

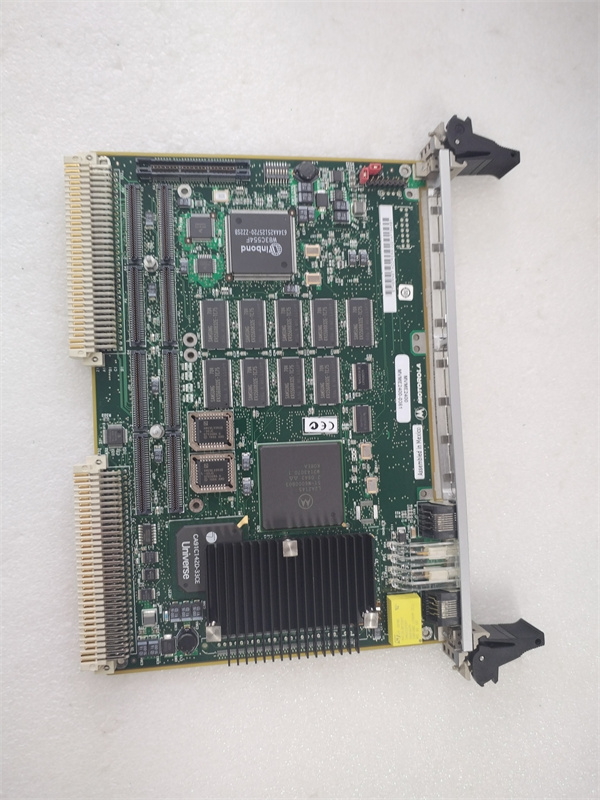

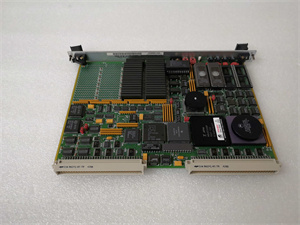

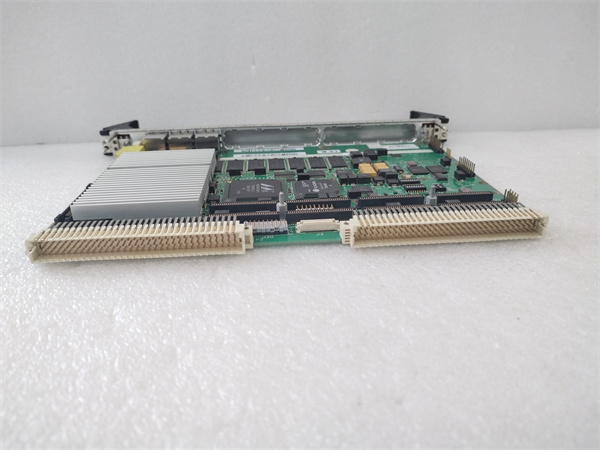

| Product Model | MVME 172PA-644SE |

| Manufacturer | Motorola |

| Product Category | 3U VMEbus High-Speed Analog Input Module |

| Analog Input Channels | 16 Differential / 32 Single-Ended Channels |

| Input Range | ±10V, ±5V, ±2.5V, 0-10V (Software Configurable) |

| Resolution | 16 Bits |

| Sampling Rate | Up to 100 kS/s (Single Channel); 500 kS/s (Total Throughput) |

| Conversion Type | Successive Approximation ADC |

| VMEbus Interface | VMEchip2 Controller (Slave, 32-bit Data Bus) |

| Form Factor | 3U Eurocard (Single-slot VME Standard) |

| Operating Temperature Range | -40°C to +85°C |

| Power Requirements | 5V DC ±5%, ±12V DC ±10% |

| Data Buffering | 1024-Word FIFO Buffer per Channel |

| Calibration | On-Board Auto-Calibration (Zero & Span) |

Motorola MVME2400

Product Introduction

The **Motorola MVME 172PA-644SE** is a high-performance 3U VMEbus analog input module designed for precision data acquisition in industrial automation and control systems. As a flagship model in Motorola’s MVME172 series, it combines 16-bit resolution with high-speed sampling capabilities to capture accurate analog signals from sensors and transducers in mission-critical applications.

Featuring 16 differential or 32 single-ended input channels, the **Motorola MVME 172PA-644SE** offers flexible configuration to match diverse signal types, with software-selectable input ranges (±10V, ±5V, ±2.5V, 0-10V). Its on-board auto-calibration ensures long-term measurement accuracy, while 1024-word FIFO buffers per channel prevent data loss during high-speed sampling. The VMEchip2 interface enables seamless integration into VMEbus-based control systems as a slave device, facilitating real-time data transfer to host CPUs. With a wide operating temperature range of -40°C to +85°C, this module delivers reliable performance in harsh industrial environments.

Core Advantages & Technical Highlights

High-Precision Measurement: The 16-bit successive approximation ADC of the **Motorola MVME 172PA-644SE** delivers exceptional measurement accuracy, with on-board auto-calibration for zero and span errors. This ensures consistent, reliable data even in temperature-fluctuating environments, critical for applications like process control and scientific data acquisition.

High-Speed Sampling Capability: With a single-channel sampling rate of up to 100 kS/s and total throughput of 500 kS/s, the **Motorola MVME 172PA-644SE** captures fast-changing analog signals (e.g., vibration, pressure transients) without aliasing. The 1024-word FIFO buffers per channel temporarily store data during peak sampling periods, preventing overflow and ensuring continuous data acquisition.

Flexible Channel Configuration: Supporting 16 differential or 32 single-ended channels, the module adapts to both balanced (noise-immune) and unbalanced signal sources. Software-configurable input ranges allow it to interface with a wide variety of sensors, from low-voltage strain gauges to high-voltage transducers, eliminating the need for external signal conditioning in many cases.

Industrial-Grade Reliability: Designed to operate in -40°C to +85°C environments, the **Motorola MVME 172PA-644SE** withstands extreme temperatures, vibration, and electromagnetic interference (EMI). Its rugged construction and high-quality components ensure stable performance in manufacturing plants, power stations, and aerospace test facilities.

Seamless VMEbus Integration: The VMEchip2 interface supports 32-bit VMEbus data transfers, enabling fast, efficient communication with host CPUs. As a slave device, it responds quickly to read commands from the host, ensuring real-time data availability for control algorithms and monitoring systems.

Typical Application Scenarios

Industrial Process Control: In chemical manufacturing plants, the **Motorola MVME 172PA-644SE** monitors temperature, pressure, and flow rate sensors across reaction vessels. Its 16-bit resolution ensures precise measurement of subtle process variations, while high-speed sampling captures transient conditions (e.g., pressure spikes) that could indicate equipment faults. Auto-calibration maintains accuracy over long production runs, reducing manual maintenance.

Power Generation Monitoring: In thermal power plants, the module collects analog data from turbine vibration sensors, generator current transformers, and boiler temperature probes. The differential input channels reject EMI from high-voltage power lines, ensuring clean signal acquisition. FIFO buffers store data during peak load periods, enabling the host system to analyze trends and detect anomalies before they cause downtime.

Aerospace Test & Measurement: In aircraft engine test cells, the **Motorola MVME 172PA-644SE** captures high-speed analog signals from thrust sensors, fuel flow meters, and exhaust gas temperature probes. Its 100 kS/s sampling rate captures dynamic engine behavior during takeoff and landing simulations, while 16-bit resolution provides the precision needed for performance validation.

Automotive Test Labs: In vehicle dynamics testing, the module acquires data from accelerometers, strain gauges, and suspension position sensors. The flexible channel configuration allows simultaneous measurement of 32 single-ended signals (e.g., from distributed sensors), while auto-calibration ensures consistent results across multiple test sessions. The rugged design withstands vibration in test rigs and environmental chambers.

Motorola MVME2400

Related Model Recommendations

Motorola MVME 172PB-644SE: Analog output companion module, paired with **Motorola MVME 172PA-644SE** to provide closed-loop control capabilities.

Motorola MVME 162-01: 3U VMEbus CPU module compatible with **Motorola MVME 172PA-644SE**, serving as the host for data processing and control.

Motorola MVME 709-1: Serial communication module, working with **Motorola MVME 172PA-644SE** to transmit acquired data to remote monitoring systems via RS-485/Modbus.

GE VMIVME-7650: Digital I/O module complementary to **Motorola MVME 172PA-644SE**, adding discrete control capabilities to data acquisition systems.

Motorola MVME 197LE: Memory expansion module for host CPUs, increasing storage for large datasets collected by **Motorola MVME 172PA-644SE**.

Motorola MVME 2300: Ethernet gateway module, enabling **Motorola MVME 172PA-644SE** to stream data to Ethernet-based SCADA systems.

Installation & Maintenance Guidelines

Installation Preparation: Before installing the **Motorola MVME 172PA-644SE**, ensure the VMEbus chassis is powered off and properly grounded. Align the module with the 3U slot guides, verifying P1/P2 backplane connector alignment. Gently insert until fully seated, then fasten front-panel screws to prevent vibration-induced disconnections. For analog wiring, use shielded twisted-pair cables for differential channels, and route cables away from high-voltage lines to minimize EMI.

Maintenance Best Practices: Perform quarterly inspections to clean dust from connectors and front-panel components using compressed air. Trigger auto-calibration monthly to maintain measurement accuracy—this can be initiated via software without removing the module. Verify power supply stability (5V ±5%, ±12V ±10%) to prevent ADC errors. Back up channel configuration settings annually to simplify reconfiguration if needed. Use only genuine Motorola spare parts to ensure VMEbus compatibility and measurement precision.

Service & Warranty Commitment

The **Motorola MVME 172PA-644SE** is backed by a 2-year manufacturer’s warranty covering defects in materials and workmanship under normal industrial operation. Motorola’s technical support team provides 24/7 assistance for critical issues, with remote diagnostics to troubleshoot calibration or data acquisition problems. We offer on-site commissioning support for complex systems, ensuring optimal integration of the **Motorola MVME 172PA-644SE** into your data acquisition setup. For legacy systems, we provide repair and calibration services to extend product lifecycle. Our commitment to quality ensures that the module delivers consistent, high-precision data, protecting your investment in industrial automation and test infrastructure.