Description

Product Overview

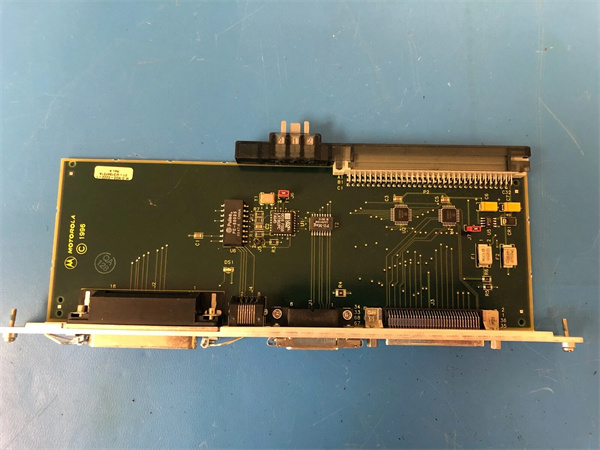

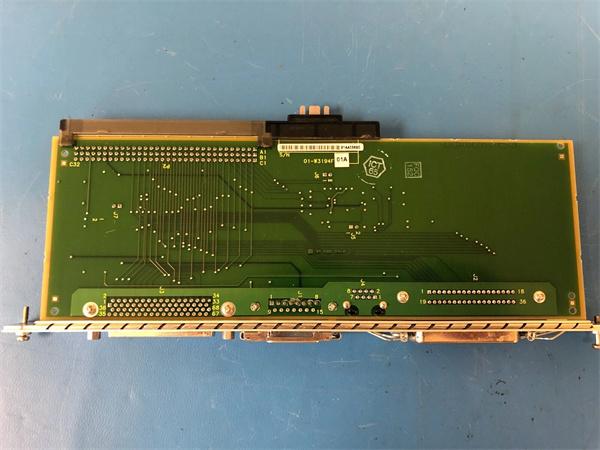

The Motorola MVME – 702 is a significant offering within Motorola’s industrial product lineup, designed to meet the complex demands of industrial control, data acquisition, and communication scenarios. As part of Motorola’s long – standing commitment to providing reliable industrial solutions, the MVME – 702 combines advanced technology with robust design to ensure seamless operation in various industrial environments.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | MVME – 702 |

| Manufacturer | Motorola |

| Product category | CompactPCI – based industrial control board (assuming a similar form – factor to related models like MVME – 705 – 1 for a space – efficient integration in industrial cabinets) |

| Input power | Likely has a wide – range power input similar to some of its counterparts, perhaps in the range of [X] – [Y] VAC. This wide power range allows it to adapt to different power supply conditions in industrial settings, whether in a factory with stable power or an area with fluctuating power grids. |

| Memory | Features [amount] of system memory, which can be partitioned for application runtime and data storage. For example, it may have [runtime_memory] for running real – time applications smoothly and [storage_memory] for storing critical data, such as sensor readings or control algorithms. This memory configuration enables efficient operation and data management in industrial applications. |

| Communication interfaces | Equipped with multiple communication ports. It may include Ethernet ports for high – speed network connectivity, facilitating connection to local area networks (LANs) or enterprise – level systems for data transfer and remote monitoring. Additionally, it could have serial ports like RS – 232/RS – 485, which are useful for interfacing with legacy industrial devices, sensors, and actuators that rely on serial communication protocols. |

| Processing power | Incorporates a high – performance microprocessor, potentially from a series known for its industrial – grade reliability and processing capabilities. This microprocessor enables the MVME – 702 to handle complex data processing tasks, such as real – time data analysis from multiple sensors, control algorithm execution, and communication protocol handling. |

| Weight | Approximately [weight_value] lbs per unit, which is designed to be lightweight enough for easy installation and handling within industrial equipment. This lightweight design also helps in reducing the overall load on industrial cabinets and mounting structures. |

| Dimensions | The board has dimensions of [length] x [width] x [height] mm, engineered to fit standard CompactPCI chassis. Its compact size maximizes space utilization in industrial control systems, allowing for the integration of multiple boards in a single chassis if required. |

| Product life cycle status | [Current life cycle status, e.g., in production, in a phase – out process, or still supported but with limited availability]. Understanding the life cycle status is crucial for customers, as it affects long – term support, spare part availability, and future upgrade options. |

Motorola MVME712-103

Product Introduction

The MVME – 702 serves as a versatile and powerful building block in industrial systems. In industrial automation, it can act as a central control unit, receiving data from a multitude of sensors distributed across a production line. For instance, in a food and beverage manufacturing plant, the MVME – 702 can collect data from temperature sensors on cooking equipment, pressure sensors on filling machines, and position sensors on conveyor belts. It then processes this data in real – time, making intelligent decisions to adjust the speed of the production line, control the operation of machinery, and ensure product quality.

In data – intensive applications such as large – scale data logging in a power generation plant, the MVME – 702’s memory and processing capabilities come into play. It can continuously record data from various sensors monitoring the performance of turbines, generators, and other power – related equipment. The Ethernet interface allows for the seamless transfer of this logged data to a central data storage system or a remote monitoring station for further analysis and reporting.

The communication interfaces of the MVME – 702 are designed to work with a wide range of industrial devices. The serial ports can be used to connect to older – generation industrial equipment that still rely on serial communication, while the Ethernet ports enable high – speed communication with modern network – connected devices, such as programmable logic controllers (PLCs), human – machine interfaces (HMIs), and cloud – based services for remote management.

Core Advantages and Technical Highlights

High – Performance Processing: The MVME – 702’s high – performance microprocessor empowers it to handle complex industrial applications with ease. It can execute real – time control algorithms, analyze large volumes of sensor data, and manage multiple communication channels simultaneously. In a high – speed manufacturing process, where quick decision – making is crucial, the MVME – 702 can process incoming data and issue control commands within milliseconds, ensuring smooth and efficient production.

Flexible Communication Options: With a combination of Ethernet and serial ports, the MVME – 702 offers unparalleled flexibility in communication. It can interface with both legacy and modern industrial devices, making it suitable for upgrading existing industrial systems or building new, integrated control systems. In an industrial complex with a mix of old and new equipment, the MVME – 702 can bridge the communication gap, enabling seamless data flow between different devices.

Reliable Design: Built with industrial – grade components, the MVME – 702 is designed to withstand harsh industrial environments. It can operate reliably in conditions with high temperatures, humidity, and electrical noise. In a mining site, where the operating environment is challenging, the MVME – 702 can continue to function without interruption, ensuring the continuous operation of critical mining equipment and systems.

Space – Efficient Form – Factor: The CompactPCI form – factor of the MVME – 702 allows for space – efficient integration in industrial cabinets. This is particularly beneficial in applications where space is limited, such as in small – scale industrial control panels or in areas where multiple boards need to be installed in a single chassis.

Typical Application Scenarios

Industrial Automation: In an automotive manufacturing plant, the MVME – 702 can be used to control and coordinate the operation of robotic arms, conveyor belts, and other automated machinery. It can receive instructions from a central control system, process sensor feedback from the production line, and ensure that each manufacturing step is executed accurately and efficiently. For example, it can control the movement of robotic arms to precisely assemble car parts, adjust the speed of conveyor belts based on the production rate, and perform quality control checks in real – time.

Smart Factory Monitoring: In a smart factory environment, the MVME – 702 can act as a data aggregation and analysis point. It can collect data from various sensors installed throughout the factory, such as energy consumption sensors, environmental sensors, and production – related sensors. By analyzing this data, it can provide insights into factory performance, identify areas for improvement, and support decision – making for optimizing production processes, energy usage, and overall factory efficiency.

Industrial IoT (IIoT) Applications: In an IIoT – enabled industrial setup, the MVME – 702 can serve as a local gateway. It can connect to a network of IoT devices, such as smart sensors and actuators, collect data from them, and transmit this data to the cloud or a central management system. In a chemical plant, the MVME – 702 can communicate with IoT – enabled valves, pumps, and storage tanks, monitoring their status and performance, and sending alerts in case of any 异常情况.

Motorola MVME712-103

Related Model Recommendations

Motorola MVME – 705 – 1: The MVME – 705 – 1, with its touchscreen and function keys, can be used in combination with the MVME – 702 in scenarios where an operator interface is required. The MVME – 702 can handle the data processing and communication tasks, while the MVME – 705 – 1 can provide an intuitive user interface for operators to monitor and control the system. In a control room for a large – scale industrial process, the MVME – 702 can process the data from the plant floor, and the MVME – 705 – 1 can display this data in a user – friendly format and allow operators to input commands.

Motorola MVME712 – 101: If enhanced communication capabilities are needed, the MVME712 – 101 can be paired with the MVME – 702. The MVME – 702 can focus on local data processing and control, while the MVME712 – 101 can handle the communication with remote devices, other industrial systems, or enterprise – level networks. In a distributed industrial system spread across multiple locations, the MVME – 702 at each site can process local data, and the MVME712 – 101 can transmit this data to a central server for centralized monitoring and management.

Motorola MVME050: As an industrial power supply module, the MVME050 can ensure a stable power supply for the MVME – 702. In harsh industrial environments, where power surges and voltage fluctuations are common, the MVME050 can protect the MVME – 702 from electrical damage and provide a reliable power source for continuous operation. In a steel mill, where the electrical environment is challenging, the MVME050 can safeguard the MVME – 702, ensuring the uninterrupted operation of the industrial control system.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MVME – 702, ensure that the CompactPCI chassis is compatible and properly grounded. Check the power supply requirements and ensure that the incoming power is within the specified range. Gather the necessary tools, such as an anti – static wristband to protect the sensitive electronic components, a screwdriver for mounting the board in the chassis, and appropriate cables for connecting to peripheral devices. Review the board’s documentation for any specific jumper settings or configuration requirements.

Commissioning: After installation, power on the system. Use diagnostic software (compatible with the CompactPCI system) to check the functionality of the MVME – 702. Verify that the microprocessor is operating correctly, the memory is accessible, and the communication ports are working. Test the connection to peripheral devices by sending and receiving sample data. Calibrate any sensors or devices connected to the MVME – 702 according to the manufacturer’s instructions.

Maintenance Suggestions: Regularly check the status of the MVME – 702. Inspect the LEDs on the board (if available) to monitor its operation status. Clean the board periodically to remove dust and debris, especially in environments with high – particulate matter. For the communication ports, check the cables and connections for any signs of wear or damage. If there are any performance issues, first check the power supply and then use diagnostic tools to identify whether it is a hardware – related issue or a problem with the software or connected devices. Keep spare MVME – 702 boards in a static – free environment for quick replacement in case of failures.

Service and Guarantee Commitment

Motorola typically provides a standard warranty for the MVME – 702, which may cover defects in materials and workmanship for a specified period, usually around 12 – 24 months (terms may vary depending on the region and sales agreement). In case of a malfunction within the warranty period, Motorola or its authorized service centers will provide repair or replacement services. For customers seeking extended support, additional service contracts can be purchased. These contracts may include priority technical support, regular system health checks, and software updates (if applicable). Motorola also offers a network of authorized resellers and service providers who can assist with installation, commissioning, and ongoing maintenance of the MVME – 702.