Description

Detailed Parameter Table

**

| Parameter name | Parameter value |

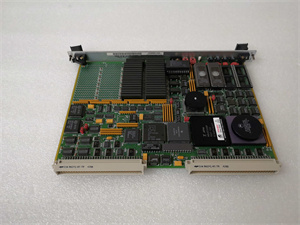

| Product model | Motorola MVME147SRF |

| Manufacturer | Motorola |

| Product category | High – performance VMEbus single – board computer module |

| Processor Options | – Optional 25 MHz MC68040 32 – bit microprocessor with 8 KB of cache, Memory Management Unit (MMU), and Floating – Point Unit (FPU). – Optional 25 MHz MC68LC040 enhanced 32 – bit microprocessor with 8 KB of cache and MMU |

| Memory | – 4, 8, or 16 MB of shared DRAM for data storage during operation. – 512 KB SRAM with battery backup to retain critical data during power outages. – 1 MB flash memory for on – board monitor/debugger or user – installed firmware |

| Storage – related | 8K x 8 Non – Volatile Random – Access Memory (NVRAM) and time – of – day clock with battery backup for maintaining system – related time – sensitive information |

| Bus Interface | A 32/64 – bit VMEbus master/slave interface with system controller function, enabling seamless integration into VME – based systems. High – performance DMA support for VMEbus D64 and local bus memory burst cycles for efficient data transfer |

| I/O Interfaces | – Two serial communication ports: Console port as EIA – 232 – D DTE and second port user – configurable for EIA – 232 – D/EIA – 422 (V.36) DTE/DCE, useful for serial data communication with other devices such as sensors or controllers. – Four 16 – or 32 – bit Industry Pack® ports with one DMA channel per port, allowing for easy addition of custom I/O functionality through Industry Pack modules. – Optional SCSI bus interface with 32 – bit local bus burst DMA for high – speed storage device connectivity if required in storage – intensive applications. – Optional Ethernet transceiver interface with 32 – bit local bus DMA for network connectivity, suitable for applications that need to communicate over a local network |

| Timers | Six 32 – bit timers (four without VMEbus) for accurate time – based operations (e.g., controlling periodic tasks in industrial automation) and one watchdog timer to ensure system stability by resetting the module in case of software or hardware malfunctions |

| Power Requirements | Input voltage range: 170 – 330 VDC (as per some sources). Power consumption details are not as widely available but is designed to operate efficiently within the industrial power supply standards |

| Operating Temperature | Designed to operate in a wide temperature range suitable for industrial environments, though specific values may vary but generally can withstand temperatures typical in factory floors, power plants, etc. |

| Physical Dimensions | – Compact size, likely in a form factor that is compatible with standard VMEbus chassis, facilitating easy installation in existing systems. Specific length x width x height dimensions are not provided in the given sources but are engineered to fit standard industrial computing enclosures |

| Weight | Approximately 2.0 kg (as per some sources), which is relatively lightweight considering its functionality and the robustness required for industrial use |

| Compatibility | Compatible with VME – based systems and a wide range of Industry Pack modules. Can work in tandem with other Motorola VMEbus components as well as third – party devices that adhere to the VMEbus standards |

| Product Life Cycle | [Indicate current status if available, e.g., discontinued but still widely used in legacy systems or in – production] |

MOTOROLA MVME147SRF

Product Introduction

The Motorola MVME147SRF is a high – performance VMEbus single – board computer module that stands as a reliable and versatile solution for a broad spectrum of industrial and embedded applications. Leveraging Motorola’s extensive experience in semiconductor and industrial computing technology, this module is meticulously engineered to meet the exacting demands of industrial environments, where reliability, performance, and flexibility are non – negotiable.

Unlike some off – the – shelf computing modules, the MVME147SRF is tailored for VME – based systems. It functions as the central processing and control hub within these systems, handling all data – related operations. In an industrial control setup, for example, the MVME147SRF can receive real – time data from multiple sensors spread across a production line. It then processes this data using its powerful processor options and sends out control signals to various actuators, ensuring smooth and efficient production processes. With its array of memory options and high – speed bus interfaces, it can handle complex algorithms and large – volume data processing tasks with relative ease.

Core Advantages and Technical Highlights

Flexible Processor Options: The availability of either the 25 MHz MC68040 with its cache, MMU, and FPU or the enhanced 25 MHz MC68LC040 with cache and MMU provides users with the flexibility to choose the processing power that best suits their application requirements. For applications that demand heavy – duty floating – point calculations, such as in scientific data acquisition in industrial research settings, the MC68040 can offer the necessary computational muscle. On the other hand, for applications that are more focused on standard data processing and control tasks, the MC68LC040 can provide a cost – effective yet high – performance solution.

Reliable Memory Configuration: The combination of shared DRAM, SRAM with battery backup, and flash memory ensures reliable data storage and retrieval. In industrial settings where power outages can occur, the battery – backed SRAM preserves critical data, preventing data loss. The flash memory, with its ability to store on – board monitor/debugger or user – installed firmware, offers convenience in system setup and maintenance. For example, in a power generation plant, the MVME147SRF’s memory configuration can ensure that the control system’s operational data and firmware remain intact during brief power disruptions, minimizing the impact on power generation processes.

Rich I/O and Expansion Capabilities: The multiple serial communication ports, Industry Pack ports, and optional SCSI and Ethernet interfaces make the MVME147SRF highly adaptable. The Industry Pack ports, in particular, allow for easy customization by adding various Industry Pack modules. In a smart factory, a user could add an Industry Pack module with additional analog input channels to interface with more sensors, expanding the data acquisition capabilities of the system. The optional SCSI interface enables high – speed storage device connectivity, useful for applications that need to store large amounts of data, such as in a data – logging system for a manufacturing process.

Typical Application Scenarios

Industrial Automation in Manufacturing Plants: In an automotive manufacturing plant, the MVME147SRF can be the core of the production line control system. It receives data from sensors that monitor the position and movement of robotic arms, conveyor belts, and other automated machinery. Using its high – speed processing and reliable memory, it processes this data and sends out control signals. For instance, it can adjust the speed of conveyor belts in real – time based on the production rate or control the precise movement of robotic arms for accurate part assembly. The module’s expansion capabilities also allow for easy integration of new sensors or actuators as the production line evolves.

Industrial Monitoring and Control in Power Plants: In a power generation plant, the MVME147SRF is used to monitor and control various aspects of the power generation process. It receives data from sensors that measure parameters such as temperature, pressure, and voltage. The module’s high – performance processor analyzes this data to detect any anomalies or potential issues. If a problem is detected, the MVME147SRF can send out control signals to adjust the operation of generators, turbines, or other equipment. Its reliable memory and robust architecture ensure continuous and accurate operation in the harsh electrical and thermal environment of a power plant.

Data Acquisition in Industrial Research: In an industrial research facility, the MVME147SRF can be used in data acquisition systems. It can interface with a variety of sensors to collect data from experiments. For example, in a materials testing laboratory, it can receive data from sensors that measure stress, strain, and temperature during material testing. The module’s floating – point processing capabilities (if the MC68040 processor is chosen) can be used to analyze the collected data in real – time, providing researchers with immediate insights into the material’s properties.

MOTOROLA MVME147SRF

Related Model Recommendations

Motorola MVME147S – 1: Similar in functionality but may have some differences in processor speed or memory configuration. It could be a more cost – effective option for applications with slightly less demanding processing requirements. For example, in a small – scale industrial control system where the data processing tasks are not as complex, the MVME147S – 1 might be a suitable alternative.

[Compatible Industry Pack module model]: A specific Industry Pack module designed to work with the MVME147SRF, providing additional functionality such as high – speed data acquisition or advanced communication interfaces. This combination can enhance the capabilities of the MVME147SRF in specific applications, like adding more digital output channels for a lighting control system in an industrial facility.

[VME – compatible power supply model]: A power supply that is optimized to provide stable power to the MVME147SRF. It ensures that the module receives the correct voltage and current, which is crucial for its reliable operation, especially in industrial environments where power fluctuations can occur.

[Industrial enclosure model]: A rugged industrial enclosure designed to house the MVME147SRF and its associated components. It provides protection against dust, moisture, and mechanical shocks, making it suitable for use in harsh industrial environments.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MVME147SRF, ensure that the VME chassis is compatible with the module’s form factor. Check the power requirements of the MVME147SRF and ensure that the power supply in the chassis can provide stable and sufficient power within the 170 – 330 VDC range (if this is the correct range for the module). Gather the necessary tools, such as a screwdriver for physical installation and an anti – static wristband to prevent electrostatic discharge damage to the sensitive components of the MVME147SRF. Also, make sure that the VME backplane has the appropriate connectors and addressing scheme for the module.

Maintenance Suggestions: For regular maintenance, monitor the temperature of the MVME147SRF during operation. If the temperature seems to be unusually high, check the cooling system (such as fans or heat sinks) in the VME chassis. Periodically update the firmware stored in the flash memory of the MVME147SRF to ensure that it has the latest performance improvements and bug fixes. If the module shows signs of reduced performance, check for any software conflicts or hardware issues, such as loose connections. In case of hardware failures, contact Motorola’s authorized service centers for replacement or repair. Additionally, regularly check the integrity of the battery – backed SRAM to ensure that critical data is being retained as expected.

Service and Guarantee Commitment

Motorola offers a [X] – month warranty for the MVME147SRF, covering any manufacturing defects in the hardware. In the event of a failure within the warranty period, they will provide free replacement or repair services. For customers who require extended support, service contracts are available. These contracts include 24/7 technical support, software updates, and priority access to replacement parts. Motorola also maintains a global network of authorized service centers, ensuring that customers can get prompt and reliable service whenever needed. This service and guarantee commitment reflects Motorola’s dedication to providing high – quality products and support to their customers in the industrial and embedded systems markets.