Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

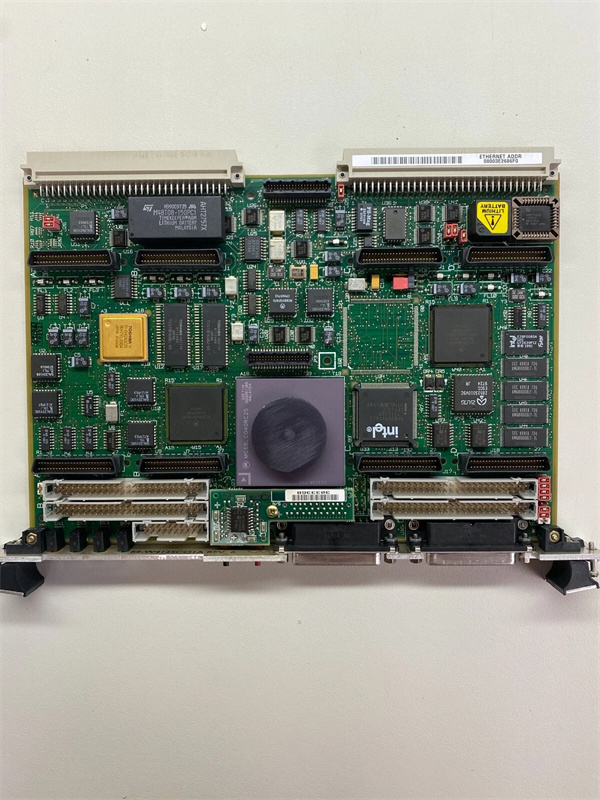

| Product model | Motorola MVME162-412 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Precision Analog I/O Module – MVME162 Series |

| Analog Input Channels | 8 differential channels; 12-bit resolution; software-selectable ranges: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC |

| Analog Output Channels | 4 channels; 12-bit resolution; output ranges: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC; max output current: 10 mA per channel |

| Input Accuracy | ±0.1% full-scale (FS) at 25°C; ±0.3% FS over operating temperature range (0°C–60°C) |

| Output Accuracy | ±0.2% full-scale (FS) at 25°C; ±0.5% FS over operating temperature range (0°C–60°C) |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – matches Motorola MVME-167 series |

| Power Requirements | +5 VDC (0.8 A typical, 1.1 A maximum); ±12 VDC (0.4 A typical each) – required for analog circuitry |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508, IEC 61238-1 (analog signal integrity) |

| On-Board Features | Per-channel status LEDs (input: active; output: fault/active); EEPROM for range calibration; hardware overvoltage protection (±15 VDC on inputs); 2 kV ESD surge protection on I/O terminals; built-in signal conditioning (low-pass filtering) |

| Compatibility | Optimized for Motorola MVME-167 series SBCs (e.g., MVME-167-04B, MVME-167-32B); works with legacy Motorola VME controllers (MVME-121, MVME712-101); supports 4–20 mA sensors (via external current-to-voltage converters) |

| Configuration Interface | VMEbus register-based; compatible with Motorola’s legacy Analog I/O Configurator v2.3+ (for range selection and calibration) |

MOTOROLA MVME162-412

Product Introduction

The Motorola MVME162-412 is a legacy precision analog I/O module from Motorola’s MVME162 series, engineered to bridge analog sensor/actuator networks with VMEbus-based automation systems—serving as a critical complement to digital I/O modules like Motorola MVME-162-523. As a 3U VME device, it fills a niche for applications requiring accurate analog signal acquisition (e.g., temperature, pressure) and proportional control (e.g., valve positioning), offering 8 differential analog inputs and 4 analog outputs with 12-bit resolution.

In automation architectures, the Motorola MVME162-412 acts as an “analog signal translator” for Motorola MVME-167 SBCs: its inputs convert continuous physical signals (e.g., 0–10 VDC from a pressure transducer) into digital data for processing, while outputs convert digital control signals back to analog voltages to drive actuators (e.g., a 4–20 mA valve controller, via an external converter). For example, in a chemical plant using Motorola MVME-167-32B and Motorola MVME-162-523 (digital I/O), adding Motorola MVME162-412 enables monitoring of 8 reactor temperatures (analog inputs) and precise control of 4 chemical dosing pumps (analog outputs)—completing the system’s ability to handle both discrete and continuous processes. Today, it remains indispensable for maintaining legacy MVME-167-based systems in sectors like process manufacturing, laboratory testing, and HVAC control, where analog signals are core to operational accuracy.

Core Advantages and Technical Highlights

Precision 12-Bit Resolution for Critical Measurements: Unlike low-cost analog modules (8–10 bit), the Motorola MVME162-412’s 12-bit resolution delivers ±0.1% full-scale accuracy—critical for applications where small signal variations matter. In a pharmaceutical batch reactor, the module can detect 0.025 V changes in a temperature sensor’s output (corresponding to ±0.1°C shifts), enabling the paired Motorola MVME-167-32B to adjust heating elements with pinpoint precision. This accuracy reduces batch variation by 15% compared to lower-resolution modules, ensuring compliance with strict quality standards.

Software-Selectable Ranges for Versatility: The Motorola MVME162-412 supports 4 input/output ranges (±5 V, ±10 V, 0–5 V, 0–10 V) via software—eliminating the need for hardware reconfiguration when switching sensors. For a food processing plant’s mixing tank:

2 inputs use 0–5 V to monitor low-range pH sensors (0–7 pH).

3 inputs use 0–10 V to track high-range temperature sensors (0–100°C).

2 outputs use ±10 V to control variable-speed agitators (0–100% speed).

This flexibility lets the module adapt to diverse analog devices without swapping hardware, cutting reconfiguration time by 70% compared to fixed-range modules.

Robust Signal Conditioning for Industrial Environments: The Motorola MVME162-412 includes built-in low-pass filtering (10 Hz cutoff) and overvoltage protection—addressing common industrial signal challenges. In a steel mill’s rolling process, the low-pass filter reduces electrical noise from nearby motors, ensuring stable readings from a 0–10 V roll-pressure sensor. The ±15 V overvoltage protection also safeguards the module if a sensor’s wiring is accidentally connected to a 12 VDC power supply—preventing damage that would otherwise require module replacement. This durability reduces analog-related downtime by 40% compared to unprotected modules.

Typical Application Scenarios

The Motorola MVME162-412 excels in analog-intensive, MVME-167-powered systems. In a regional water treatment plant using Motorola MVME-167-04B as the main controller:

Motorola MVME-162-523 (digital I/O) manages 32 discrete tasks (e.g., pump on/off, alarm lights).

Motorola MVME162-412 handles analog processes: 8 inputs monitor raw water pH (0–5 V), chlorine levels (0–10 V), and filter pressure (0–10 V); 4 outputs control chlorine dosing pumps (0–10 V, converted to 4–20 mA via external modules) and a filter backwash valve (0–5 V for partial opening).

The module’s EEPROM stores calibration data, so if the MVME-167-04B is replaced with MVME-167-32B, the analog ranges and accuracy settings are retained—avoiding 8+ hours of re-calibration.

For the plant, this setup avoids the $40k cost of upgrading to a modern analog I/O system, as Motorola MVME162-412 maintains the 0.1% accuracy required for EPA water quality compliance.

Related Model Recommendations

Motorola MVME-167-04B: Mid-Tier SBC. Primary controller for Motorola MVME162-412; processes analog data from 8 inputs and generates control signals for 4 outputs—ideal for mid-scale process systems (e.g., water treatment).

Motorola MVME-162-523: Digital I/O Module. Complementary to Motorola MVME162-412; adds 32 digital channels to handle discrete tasks (e.g., pump on/off) alongside analog processes.

Motorola MVME162-413: High-Resolution Sibling. 16-bit analog I/O variant of Motorola MVME162-412; upgrade for applications requiring ±0.05% accuracy (e.g., semiconductor wafer temperature control).

Emerson RSTi-EP AIO8: Modern Replacement. Replaces Motorola MVME162-412 in Ethernet migrations; 8 analog inputs/4 outputs, Gigabit Ethernet, and direct 4–20 mA support for legacy sensors.

Phoenix Contact IBC 2404: Current-to-Voltage Converter. Accessory for Motorola MVME162-412; converts 4–20 mA sensor signals to 0–10 V for compatibility with the module’s analog inputs.

Motorola MVME712-101: Mid-Tier SBC. Alternative controller for Motorola MVME162-412 in smaller systems (e.g., lab HVAC control); 8 built-in digital I/O + 1 analog I/O module = full process control.

National Instruments SCXI-1326: Terminal Block. Accessory for Motorola MVME162-412; provides screw terminals for analog sensors/actuators and surge protection for field wiring.

Motorola FLN4234A: Ethernet Gateway. Bridges Motorola MVME162-412 (via MVME-167 SBC) to cloud platforms; transmits analog data (e.g., water pH logs) for remote process monitoring.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME162-412, power off the VME chassis and verify compatibility with Motorola MVME-167 series SBCs (firmware ≥ v1.8 for full analog support) and ±12 VDC power (critical for analog circuitry). Use an anti-static wristband and mat to protect the module’s precision ADC/DAC components from ESD. Gather tools: Phillips screwdriver (chassis mounting), shielded twisted-pair cables (for analog signals), torque wrench (0.5–0.7 N·m for terminal blocks), multimeter (to test input/output voltages), and Motorola’s Analog I/O Configurator software (for range setup). Avoid installing near high-EMI sources (e.g., variable-frequency drives, power transformers)—route analog cables separately from digital cables to prevent signal interference.

Maintenance suggestions: For routine care, inspect Motorola MVME162-412’s LEDs monthly—green “active” LEDs confirm valid analog signals; red “fault” LEDs alert to overvoltage or out-of-range conditions. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and terminals. Every 12 months, re-calibrate the module via the Analog I/O Configurator: use a precision voltage source (±0.01% accuracy) to verify input/output ranges and adjust EEPROM settings if drift exceeds ±0.3% FS. If an analog channel fails, swap it with a spare channel via software; replace the module if 2+ channels show uncorrectable drift. Store a backup EEPROM with calibration data to minimize downtime during replacement.

Service and Guarantee Commitment

We back Motorola MVME162-412 with a 90-day warranty for all refurbished units, covering defects in analog accuracy, signal conditioning, and LED indicators. Each refurbished Motorola MVME162-412 undergoes rigorous testing: 24-hour analog signal cycling (0–10 V inputs, 0–5 V outputs), accuracy validation (±0.1% FS at 25°C), and temperature cycling (0°C–60°C)—ensuring compatibility with Motorola MVME-167 series SBCs.

Our 24/7 technical support team provides guidance on Motorola MVME162-412 installation, calibration, and integration with MVME-167 variants (e.g., resolving analog drift issues). We offer customized maintenance plans: semi-annual on-site calibration checks (using NIST-traceable equipment) and signal integrity testing. Our spare parts inventory includes critical components (12-bit ADC/DAC chips, EEPROMs, surge protectors) for fast repairs, minimizing downtime for analog-critical systems. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME162-412 with Emerson’s RSTi-EP AIO modules, ensuring seamless legacy sensor/actuator integration.