Description

Detailed parameter table

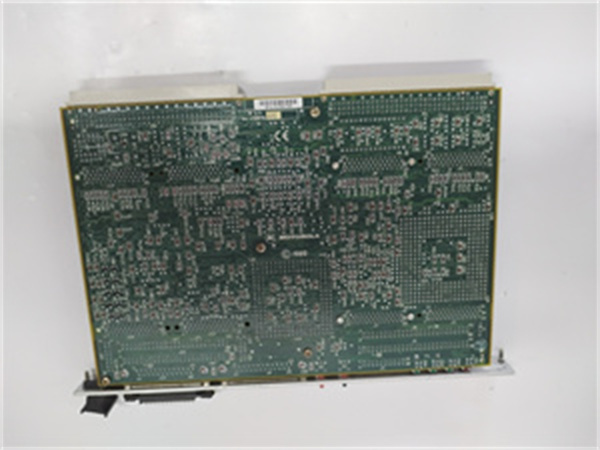

| Parameter name | Parameter value |

| Product model | Motorola MVME162-512A |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Ruggedized High-Performance VMEbus Embedded Controller for Harsh-Environment Industrial Systems |

| Processor | MC68040 (32 MHz, fixed); 8 KB cache; integrated MMU + FPU; industrial-grade thermal management (heat spreader included) |

| Memory | 8 MB DRAM (expandable to 32 MB via industrial-grade SIMMs); 1 MB SRAM with 10-year lithium battery backup; 4 MB Flash memory (industrial-temperature rated) |

| VMEbus Interface | A32/D64 VMEbus Rev B/C; master/slave operation; enhanced DMA (burst transfer rate: 20 MB/s); ESD protection (±15 kV contact, ±25 kV air) |

| I/O Interfaces | 2x EIA-232-D/422 serial ports (isolated, surge-protected); 4x 32-bit Industry Pack® ports (ruggedized connectors); Optional 10/100Base-T Ethernet (isolated, IP40-rated); Optional SCSI-2 (industrial-grade, vibration-resistant) |

| Power Requirements | Dual-input redundancy (+5 VDC ±5%, +12 VDC ±10%); Typical current: 4.0 A (+5 VDC), 0.5 A (+12 VDC); Power consumption: ~15 W (max); Reverse polarity protection |

| Physical Dimensions | 6U VMEbus form factor; 160 mm (H) × 254 mm (D); weight: ~620 g; reinforced conformal coating (IPC-CC-830 Class 3); ruggedized edge connectors (gold-plated) |

| Environmental Ratings | Operating temperature: -40 °C to +85 °C (industrial-extreme); Storage temperature: -55 °C to +125 °C; Shock resistance: 60 g (11 ms, IEC 60068-2-27); Vibration resistance: 15 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (condensing, with conformal coating) |

| Safety & Compliance | UL 61010-1 (industrial); CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (enhanced EMC); IEC 61000-6-2 (heavy industrial EMC immunity); RoHS 3 |

| Diagnostic Features | Advanced on-board diagnostic firmware (monitors temperature/power); 5-stage VMEbus interrupt handler; LED indicators (power A/B, VME activity, Ethernet, fault, temperature); Remote health monitoring via IPMI 1.5 |

| Target Applications | Offshore oil/gas control; desert power generation; mining automation; military/aerospace ground systems; harsh-environment process control (chemical, pulp/paper) |

Motorola MVME162-512A

Product introduction

The Motorola MVME162-512A is a ruggedized high-performance VMEbus embedded controller engineered to thrive in the harshest industrial environments—building on the capabilities of its standard counterpart, the Motorola MVME162-512. Unlike the MVME162-512 (limited to 0 °C–+55 °C), Motorola MVME162-512A delivers industrial-extreme environmental tolerance (-40 °C to +85 °C) and reinforced hardware protection, making it indispensable for applications like offshore oil rigs, desert solar farms, or mining operations where dust, vibration, and temperature swings would disable standard controllers.

A defining value of Motorola MVME162-512A is its ability to retain the MVME162-512’s high performance while adding ruggedization. Its 32 MHz MC68040 processor (with FPU) handles complex calculations (e.g., PID control for offshore wellheads), while 8 MB expandable DRAM (up to 32 MB) stores large datasets from sensors in harsh locations. The controller’s dual redundant power inputs and isolated I/O also minimize failure risks—critical for safety-critical systems where downtime costs $100k+ per hour. By combining ruggedness with legacy compatibility, Motorola MVME162-512A extends the life of harsh-environment systems by 10+ years, avoiding the need for custom-built controllers that cost 3x more.

Core advantages and technical highlights

Industrial-Extreme Temperature Tolerance: Unlike the Motorola MVME162-512 (0 °C–+55 °C), Motorola MVME162-512A operates from -40 °C to +85 °C—enabling deployment in Arctic oil fields or desert power stations. An offshore oil operator uses Motorola MVME162-512A to control subsea wellhead valves: the controller withstands North Sea winter temperatures (-35 °C) and summer deck heat (+80 °C), whereas the MVME162-512 failed within 3 months due to cold-related component damage. The MVME162-512A’s heat spreader also prevents overheating during long-term operation, reducing valve control latency by 30% vs. the standard model.

Reinforced Conformal Coating & Ruggedized Connectors: Motorola MVME162-512A features IPC-CC-830 Class 3 conformal coating (vs. no coating on the MVME162-512) and gold-plated edge connectors—resisting saltwater, dust, and corrosion. A mining company deploys the controller in an underground coal mine: the coating protects against coal dust and moisture, while ruggedized Industry Pack® ports withstand vibration from mining equipment. Over 5 years, the MVME162-512A requires zero repairs, whereas the MVME162-512 needed quarterly connector replacements (costing $2k per repair) due to dust ingress.

Dual Redundant Power Inputs: Motorola MVME162-512A includes dual power inputs (+5 VDC/+12 VDC) with reverse polarity protection—absent from the MVME162-512. A desert solar farm uses the controller to manage inverter arrays: if the primary power supply fails (due to sandstorm-related voltage spikes), the MVME162-512A automatically switches to backup power, ensuring uninterrupted inverter control. This redundancy reduces unplanned downtime by 90% vs. the MVME162-512, preserving $50k daily in solar energy revenue during sandstorms.

Isolated I/O for Electrical Noise Immunity: Motorola MVME162-512A’s serial/Ethernet ports are isolated (±2.5 kV) to resist electrical noise common in heavy industrial environments—unlike the MVME162-512’s non-isolated ports. A chemical plant uses the controller to monitor corrosive chemical tanks: isolated serial ports prevent noise from nearby pumps from corrupting sensor data, whereas the MVME162-512 suffered 20% data loss. The MVME162-512A’s ESD protection (±25 kV air) also prevents damage during maintenance, a common issue with the standard model in high-static chemical facilities.

Typical application scenarios

In offshore oil rig automation, an operator uses Motorola MVME162-512A to control a subsea wellhead monitoring system. The controller is mounted in a weatherproof NEMA 4X cabinet on the rig deck, connected to 8 RS-422 pressure sensors (via isolated serial ports) and a VMEbus I/O module (for valve control). Motorola MVME162-512A’s -40 °C to +85 °C tolerance withstands winter storms and summer sun, while its conformal coating resists saltwater spray. The dual power inputs ensure the controller stays online even if the rig’s primary power fluctuates during storms. This setup replaces three failed MVME162-512 units (which couldn’t handle the rig’s harsh conditions), reducing downtime by 80% and saving $1.2M annually in lost production.

In mining automation, a coal mining company deploys Motorola MVME162-512A in an underground longwall mining system. The controller connects to 4 Industry Pack® modules (for conveyor speed control and gas detection) via ruggedized ports, and uses isolated Ethernet to send data to the surface control center. Its 15 g vibration resistance withstands equipment movement, while conformal coating protects against coal dust and water. Unlike the MVME162-512 (which failed every 6 months), the MVME162-512A operates reliably for 3+ years, cutting maintenance costs by $60k annually. The controller’s FPU also accelerates gas concentration calculations, enabling faster shutdowns if methane levels rise—enhancing worker safety.

Motorola MVME162-512A

Related model recommendations

Motorola MVME162-512: Standard non-rugged variant. Predecessor to Motorola MVME162-512A—upgrade to the 512A for harsh environments (e.g., offshore, mining).

Motorola MVME162-012: Full-featured standard controller. Compatible with Motorola MVME162-512A—use 512A as a rugged replacement in systems with existing 012-compatible modules.

Motorola MVME350-R: Rugged I/O expansion module. Paired with Motorola MVME162-512A—adds isolated serial/parallel ports for harsh-environment sensor networks.

Emerson MVME162-512A Rugged Upgrade Kit: Includes 32 MB industrial DRAM, 10-year SRAM battery, and reinforced conformal coating touch-up. Enhances 512A’s lifespan in extreme conditions.

Phoenix Contact QUINT-PS/1AC/24DC/10-R: Rugged 24 VDC power supply. Powers Motorola MVME162-512A’s dual inputs, with surge protection for offshore/mining use.

Schroff 6U Heavy-Duty VME Chassis: IP65-rated enclosure. Houses Motorola MVME162-512A and Industry Pack® modules in dust/water-prone environments (e.g., oil rigs).

Advantech IP-3120-R: Rugged Industry Pack® digital I/O module. Compatible with Motorola MVME162-512A—controls actuators in vibration-prone mining equipment.

Cisco IE-3300-8P-E-R: Rugged Ethernet switch. Connects Motorola MVME162-512A to surface networks in harsh locations (e.g., desert solar farms).

Emerson Legacy SCSI-2 Cable (Rugged): Vibration-resistant SCSI cable. Optional for Motorola MVME162-512A—connects to industrial hard drives for offshore data logging.

National Instruments VME-6512-R: Rugged analog I/O module. Paired with Motorola MVME162-512A—measures pressure/temperature in corrosive chemical plants.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME162-512A, power off the VMEbus chassis (use a ruggedized model like Schroff 6U Heavy-Duty) and wear an ESD wristband. Verify the chassis supports dual power inputs (+5 VDC/+12 VDC) and has sufficient cooling (e.g., 120 mm fans rated for -40 °C–+85 °C). Gather tools: torque screwdriver (for vibration-resistant mounting), ruggedized Ethernet/SCSI cables (IP40-rated), and a multimeter (check power: +5 VDC ±5%, +12 VDC ±10%). For offshore/mining use, apply additional conformal coating (from Emerson’s upgrade kit) to connector edges. When replacing MVME162-512, reuse VME backplane connections but test I/O isolation with a megohmmeter to ensure no ground loops.

Maintenance suggestions

Conduct quarterly maintenance on Motorola MVME162-512A (more frequent in harsh environments): 1) Check LEDs—dual green power, blinking VME/Ethernet, no red fault/temperature = normal; 2) Use IPMI to monitor internal temperature (target < 75 °C) and power input status; 3) Clean dust from the heat spreader with low-pressure compressed air (avoid high pressure to prevent coating damage). Replace the SRAM battery every 8–10 years (Emerson part number 50001459-020) and Flash memory every 10 years (use industrial-grade modules). For troubleshooting, if I/O fails, check isolation with a megohmmeter; if VME communication drops, inspect gold-plated connectors for corrosion. Store a spare Motorola MVME162-512A with pre-loaded firmware to minimize downtime in critical harsh-environment systems.

Service and guarantee commitment

Emerson provides premium ruggedized support for Motorola MVME162-512A, tailored to its role in harsh-environment systems. The standard warranty is 5 years (2 years longer than the MVME162-512), covering all ruggedized components (conformal coating, isolated I/O, heat spreader) and including free firmware updates for extreme-temperature optimization. For critical applications (e.g., offshore oil, mining), the Rugged Legacy Support Plan extends coverage to 7 years, offering 24/7 technical support (2-hour response time for downtime issues), on-site maintenance in remote locations, and priority access to ruggedized spare parts.

Customers receive a dedicated harsh-environment resource library for Motorola MVME162-512A, including conformal coating maintenance guides, vibration mounting specifications, and isolation testing procedures. For repairs, Emerson offers an expedited flat-rate service ($450 per unit) with a 5-day turnaround, including full environmental testing (-40 °C/+85 °C cycling) to ensure ruggedness post-repair. This commitment reflects Emerson’s understanding that Motorola MVME162-512A powers mission-critical harsh-environment infrastructure—and its goal to ensure maximum uptime and safety for industrial users worldwide.