Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME162-533A |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Analog Input/Output (I/O) Module (industrial-grade signal acquisition & control) |

| Input Channel Configuration | 8 differential analog input channels (configurable for single-ended use) |

| Output Channel Configuration | 4 analog output channels (voltage/current selectable per channel) |

| Input Signal Range | ±5 VDC, ±10 VDC (software-selectable); unipolar 0–5 VDC, 0–10 VDC (configurable) |

| Output Signal Range | Voltage: ±5 VDC, ±10 VDC; Current: 4–20 mA, 0–20 mA (software-selectable per channel) |

| Resolution | Input: 12-bit ADC (0.024% full-scale accuracy); Output: 12-bit DAC (0.024% full-scale accuracy) |

| Sampling Rate (Inputs) | Up to 50 kSPS (aggregate); 6.25 kSPS per input channel (sequential sampling) |

| Update Rate (Outputs) | Up to 10 kSPS per channel (simultaneous updates supported) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 16-bit address/data bus; slave-only mode |

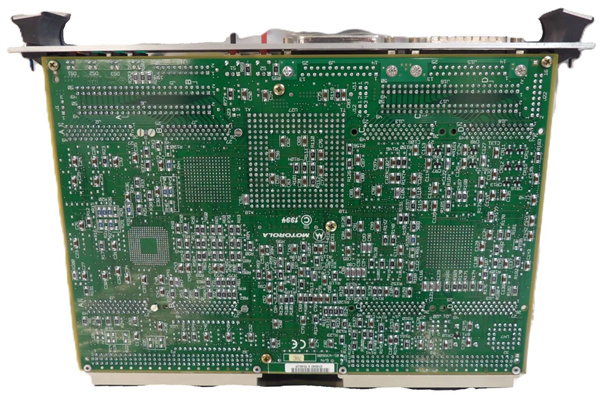

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.5 A typical, 2.0 A maximum); +12 VDC (0.4 A typical); -12 VDC (0.4 A typical); passive heat dissipation (no fan) |

| Signal Isolation | Input channel-to-channel isolation (250 Vrms); module-to-bus isolation (500 Vrms); outputs galvanically isolated from inputs |

| Calibration | On-board precision voltage/current references; software-calibratable (no manual trim pots) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F) (industrial-grade environmental tolerance) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2 (industrial EMC immunity) |

| On-Board Features | Programmable gain (1x, 2x, 4x, 8x) for inputs; output overcurrent protection; status LEDs for power, input activity, and output faults |

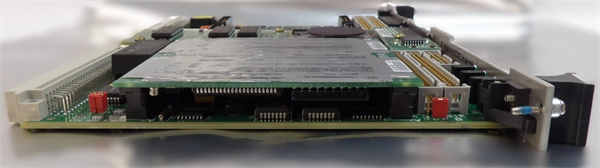

MOTOROLA MVME162-533AMOTOROLA MVME162-533A

Product Introduction

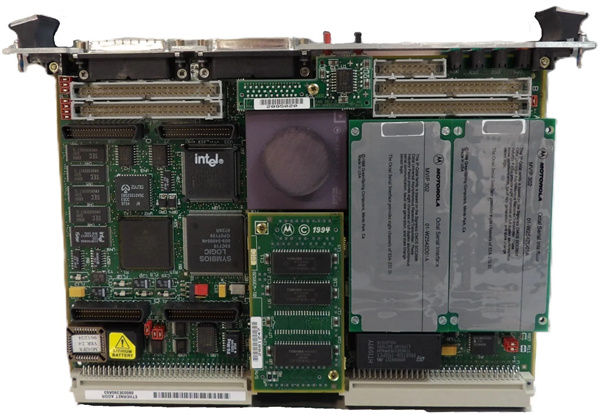

The Motorola MVME162-533A is a dual-function VMEbus analog I/O module, purpose-built to complement Motorola’s MVME series single-board computers (SBCs) such as the Motorola MVME172-263/260 in industrial automation systems. Unlike dedicated analog input modules like the Motorola MVME162PA-344, this 3U VME form factor device integrates both 8 analog input channels and 4 analog output channels—enabling end-to-end signal processing, from real-world data acquisition to active process control, in a single module.

A key differentiator of the Motorola MVME162-533A is its flexible I/O configuration: input channels handle signals from sensors (e.g., temperature, pressure), while output channels drive actuators (e.g., valves, pumps) to adjust process variables. The module’s 12-bit ADC/DAC ensures precise conversion, critical for applications where both measurement accuracy and control responsiveness matter. Its VMEbus compatibility allows seamless integration with MVME SBCs, eliminating the need for additional interface hardware and simplifying system design.

Whether deployed in closed-loop process control, condition monitoring with corrective action, or test benches requiring both measurement and stimulus, the Motorola MVME162-533A delivers reliability. Its galvanic isolation between inputs and outputs prevents cross-talk, while output overcurrent protection safeguards both the module and connected actuators. These features make it an ideal all-in-one solution for legacy VME-based systems that demand compact, integrated analog I/O capabilities.

Core Advantages and Technical Highlights

Integrated Analog I/O for Compact System Design

The Motorola MVME162-533A eliminates the need for separate input and output modules, reducing VME chassis slot usage by 50% compared to pairing a dedicated input module (e.g., Motorola MVME162PA-344) with a standalone output module. This compact design is critical for space-constrained environments, such as mobile industrial control cabinets or test benches with multiple peripherals. For example, in a portable water treatment system, the module’s 8 inputs monitor pH, flow, and level, while its 4 outputs control chemical dosing pumps and valve actuators—all in a single 3U slot, freeing space for communication or power modules.

Flexible Input/Output Configuration with Precision

With 12-bit resolution for both ADC (inputs) and DAC (outputs), the Motorola MVME162-533A ensures consistent accuracy across measurement and control. Input channels support software-selectable ranges (±5 VDC/±10 VDC) and programmable gain (1x–8x), adapting to low-voltage sensors (e.g., 0–5 VDC temperature probes) and high-voltage transducers (e.g., ±10 VDC pressure sensors). Output channels offer dual-mode operation (voltage/current), enabling compatibility with diverse actuators: 4–20 mA current outputs drive long-distance valves (common in oil refineries), while ±10 VDC voltage outputs control precision pumps in pharmaceutical manufacturing. This flexibility eliminates the need for actuator-specific adapters, reducing inventory costs.

Robust Isolation and Fault Protection

The Motorola MVME162-533A features multi-layer isolation: 250 Vrms between input channels, 500 Vrms between module and VMEbus, and galvanic isolation between inputs and outputs. This prevents ground loops and cross-talk—critical in industrial settings with multiple power sources. For instance, in a factory where input sensors are powered by a 24 VDC supply and outputs connect to a 480 VAC motor controller, isolation ensures voltage spikes from the motor don’t corrupt sensor data. Additionally, output overcurrent protection (250 mA max per channel) shuts down faulty outputs to prevent damage to the module or actuators, such as a shorted valve coil—reducing maintenance costs and unplanned downtime.

Software-Calibrated for Long-Term Reliability

Like the Motorola MVME162PA-344, the Motorola MVME162-533A uses on-board precision references for software calibration of both inputs and outputs. Technicians can calibrate the module remotely via the VMEbus, without accessing the chassis—saving time during scheduled maintenance. Calibration adjusts for ADC/DAC drift caused by temperature or aging, ensuring accuracy over the module’s lifespan. For example, in a power plant where the module operates at 60°C, annual software calibration restores input accuracy for boiler temperature sensors and output precision for steam valve controls, avoiding costly process deviations.

Typical Application Scenarios

The Motorola MVME162-533A excels in closed-loop industrial control systems, often paired with SBCs like the Motorola MVME172-263/260. In pharmaceutical batch manufacturing, it manages bioreactor conditions: 8 input channels monitor cell culture temperature (±5 VDC), pH (0–5 VDC), dissolved oxygen (0–10 VDC), and agitation speed (±10 VDC). The host SBC analyzes this data and sends control signals to the module’s 4 outputs: 4–20 mA current outputs adjust heating elements and oxygen injectors, while ±10 VDC voltage outputs control agitation motors and nutrient pumps. The module’s isolation prevents electrical noise from disrupting sensitive cell culture data, and overcurrent protection safeguards expensive bioreactor components—ensuring compliance with FDA regulations for process consistency.

In HVAC control for large data centers, the Motorola MVME162-533A optimizes cooling systems: inputs 1–4 capture server rack temperatures (0–5 VDC) via thermistors, inputs 5–8 monitor chilled water pressure (±10 VDC). The SBC uses this data to modulate the module’s outputs: 4–20 mA outputs control chilled water valves (adjusting flow based on temperature), and ±5 VDC outputs regulate fan speeds. The module’s 10 kSPS output update rate ensures rapid response to temperature spikes, preventing server overheating. Its passive cooling design withstands the warm environment of data center control rooms, while VMEbus integration simplifies communication with the data center’s SCADA system for centralized monitoring.

For automotive engine test benches, the Motorola MVME162-533A acts as a stimulus-response module: inputs 1–6 measure engine parameters (e.g., coolant temperature ±5 VDC, oil pressure 0–10 VDC), inputs 7–8 capture exhaust gas levels (0–5 VDC). The SBC uses this data to generate output signals: 4–20 mA outputs control fuel injectors, ±10 VDC outputs adjust throttle position. The module’s programmable input gain amplifies small signals from pressure sensors, allowing engineers to detect subtle engine performance issues. Paired with the Motorola MVME172-263/260, it enables real-time tuning of engine parameters, accelerating the development of fuel-efficient, low-emission engines.

MOTOROLA MVME162-533A

Related Model Recommendations

Motorola MVME162PA-344: MVME162 series analog input module (16 channels). Complements Motorola MVME162-533A in systems needing more input channels (e.g., multi-sensor condition monitoring), while the MVME162-533A handles output control.

Motorola MVME162-520: VMEbus analog I/O module (16 inputs + 8 outputs). Upgrades Motorola MVME162-533A for high-channel-count applications (e.g., large-scale chemical plants) requiring more I/O density.

Motorola MVME172-263/260: MVME172 Series SBC (68040 CPU). Host SBC for Motorola MVME162-533A, processing input data and generating output control signals—essential for closed-loop operation.

Emerson MVME5500: Modern VMEbus SBC (PowerPC CPU). Replacement for legacy MVME SBCs, compatible with Motorola MVME162-533A to add Ethernet/IP connectivity and faster processing for large datasets.

Motorola MVME712M: VMEbus communication module (dual Ethernet). Transmits Motorola MVME162-533A’s I/O data (via host SBC) to remote control centers (e.g., HVAC SCADA systems) for centralized management.

Emerson RSTi-EP AO Module: Ethernet-based analog output module. Alternative for users migrating from VME to Ethernet; pairs with Emerson RSTi-EP AI modules to replicate Motorola MVME162-533A’s I/O functionality in modern systems.

Motorola MVME162-510: VMEbus analog output module (8 channels). Dedicated output module for users who need more outputs than Motorola MVME162-533A (4 channels) but already have an input module (e.g., MVME162PA-344).

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola MVME162-533A, power off the VME chassis and disconnect it from the main supply to prevent electrical shock. Verify the chassis supports 3U VME modules and that the power supply meets the module’s requirements (+5 VDC 2.0 A max, ±12 VDC 0.4 A each). Use an anti-static wristband and mat to protect the module’s ADC/DAC and isolation components from ESD damage. Gather tools: Phillips-head screwdriver (for chassis screws) and VMEbus termination plug (if the module is the last in the slot). For wiring, use shielded twisted-pair cables for inputs (reduces EMI) and 22–18 AWG wires for outputs (handles current loads). Avoid installing near high-voltage equipment (e.g., motor starters) or heat sources (e.g., power supplies) to prevent signal interference or overheating.

Commissioning and Maintenance

For commissioning, power on the chassis and check the Motorola MVME162-533A’s LEDs: steady green “POWER” confirms voltage; blinking “INPUT ACTIVE” indicates data acquisition; “OUTPUT OK” (green) or “OUTPUT FAULT” (red) signals output status. Use the host SBC’s configuration software (e.g., Motorola MVMEbug) to set input ranges/gain and output modes (voltage/current) per channel. Calibrate inputs by applying a known voltage (e.g., 5.000 VDC) and running the software utility; for outputs, measure the current/voltage with a precision meter and adjust via calibration tools. Test closed-loop operation: connect a sensor to an input and an actuator to an output, then verify the SBC adjusts the output based on input changes (e.g., increasing valve flow if pressure drops).

For maintenance: Clean the module quarterly with compressed air to remove dust from the heatsink (prevents overheating). Perform annual software calibration of both inputs and outputs using a precision voltage/current source (±0.001 V/A accuracy) to correct drift. Inspect wiring bi-annually: check input shields for damage (maintains EMI immunity) and output wires for fraying (prevents short circuits). If an output fault occurs, first check the actuator for shorts, then use the SBC’s diagnostics to reset the module’s overcurrent protection. When replacing the module, replicate the old unit’s calibration settings (gain, range, output mode) to ensure system consistency.

Service and Guarantee Commitment

Though Motorola MVME162-533A is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in materials, workmanship, isolation performance, and output protection. Each refurbished module undergoes rigorous testing: 48-hour burn-in at 60°C (validates thermal stability), ADC/DAC accuracy checks (using NIST-traceable references), and isolation resistance testing (ensures 500 Vrms module-to-bus protection). This guarantees the module meets original industrial-grade standards.

Our technical support team (24/7 availability) provides guidance on Motorola MVME162-533A installation, calibration, and closed-loop system integration—including pairing with SBCs like the Motorola MVME172-263/260 or Motorola MVME162PA-344 input modules. We offer customized maintenance plans: quarterly remote calibration verification (via VMEbus) and on-site wiring inspections to prevent fault-related downtime. Our spare parts inventory includes critical components (e.g., DAC chips, overcurrent protection fuses) for fast repairs.

For users migrating to Ethernet-based systems, we provide free consultation to select compatible Emerson RSTi-EP I/O modules, ensuring seamless replacement of Motorola MVME162-533A while retaining existing sensors/actuators. We also offer trade-in credits for old units, reducing modernization costs. Our commitment to legacy support ensures your analog control systems remain reliable, whether you maintain VME infrastructure or transition to new platforms.