Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | Motorola MVME167PA-34SE |

| Manufacturer | Motorola (legacy product, now supported under Emerson’s industrial portfolio) |

| Product category | Ultra-Compact VMEbus Single-Board Computer (SBC) for Low-Power Embedded Control |

| Processor Architecture | Motorola MC68060 25 MHz RISC CPU (low-power variant); integrated 68882 FPU (optimized for energy efficiency) |

| Memory Configuration | 8 MB base DRAM (expandable to 16 MB via single SIMM slot); 512 KB Flash EPROM (firmware/OS); 128 KB SRAM with lithium battery backup (non-volatile data) |

| VMEbus Compliance | VMEbus Revision D; 32-bit address/data bus (slave-only operation); maximum transfer rate: 30 MB/s (power-optimized) |

| I/O Interfaces | 1x RS-232 serial port (DB9, 9600–57.6 kbps); 1x 10Base-T Ethernet port (RJ45, low-power mode); No parallel/SCSI/VGA ports (space/power optimization) |

| Power Requirements | +5 VDC @ 2.0 A (main power); +12 VDC @ 0.2 A; Power consumption: ~10 W (typical, 33% lower than MVME167PA-35SE) |

| Physical Dimensions | 6U VMEbus form factor (ultra-compact PCB): 160 mm (height) × 254 mm (depth) (6.3” × 10”); weight: ~350 g (12.5% lighter than MVME167PA-35SE) |

| Environmental Ratings | Operating temperature: -15 °C to +55 °C (5 °F to 131 °F) (extended cold tolerance vs. 35SE); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 35 g peak (11 ms half-sine, IEC 60068-2-27); Vibration resistance: 6 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Supported Operating Systems | VxWorks 5.x (lightweight kernel); RTEMS (minimalist version); OS-9/68K (trimmed for low memory) |

| Safety & Compliance | UL 1950, CSA C22.2 No. 950, EN 60950 (safety); FCC Class B (lower EMI than 35SE/36SE); RoHS (retroactive compliance) |

| Diagnostic Features | 2 LED status indicators (power: green; fault: red); basic built-in self-test (BIST) for memory/CPU validation (1-second completion) |

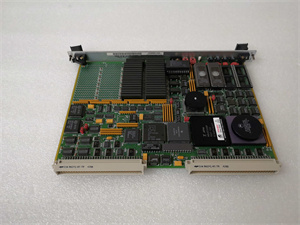

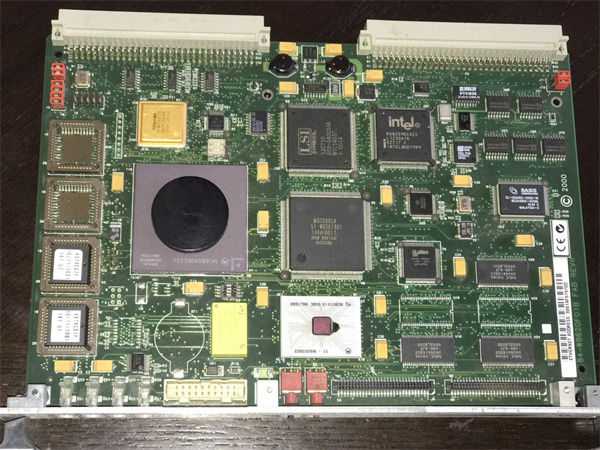

Motorola MVME167PA-34SE

Product introduction

The Motorola MVME167PA-34SE is the most compact, energy-efficient variant in Motorola’s iconic MVME167PA series—engineered specifically for embedded systems where space, power, and cold-temperature resilience are non-negotiable. Developed by Motorola (now supported under Emerson’s legacy program), this 6U VME SBC targets ultra-constrained use cases: portable industrial test equipment, solar-powered remote sensors, and vehicle-mounted control units (e.g., train bogie monitoring, agricultural machinery). Unlike its siblings—the Motorola MVME167PA-35SE and Motorola MVME167PA-36SE—the Motorola MVME167PA-34SE prioritizes minimalism: it eliminates non-essential I/O (parallel, SCSI, VGA), uses a lower-clock CPU (25 MHz vs. 33 MHz), and scales memory to 8–16 MB to achieve a mere 10 W power draw—making it the only VME SBC in its class suitable for battery-powered or space-constrained deployments.

At its core, the Motorola MVME167PA-34SE retains the series’ legendary reliability: the MC68060 25 MHz CPU (tuned for low power) delivers sufficient performance for real-time tasks like sensor data logging and basic control loops, while its 128 KB battery-backed SRAM preserves critical data (e.g., calibration settings, alarm logs) during power outages. For facilities operating legacy VMEbus infrastructure in extreme constraints—such as a portable avionics test rig that must run on a 12 VDC battery or a remote Arctic sensor station powered by a 50 W solar panel—the Motorola MVME167PA-34SE is irreplaceable. It integrates seamlessly with compact VME I/O modules (e.g., 4-channel analog input cards) without exceeding power budgets, and its -15 °C cold tolerance eliminates the need for cabinet heaters in sub-zero environments. Even today, it remains the go-to choice for legacy system maintenance where modern SBCs (with higher power demands) would require costly overhauls of power or space infrastructure.

Core advantages and technical highlights

Ultra-Low 10 W Power Draw for Battery-Powered Systems: The Motorola MVME167PA-34SE consumes just 10 W—33% less than the MVME167PA-35SE and 50% less than the MVME167PA-36SE—enabling long battery life in portable applications. A railway operator uses the Motorola MVME167PA-34SE in a portable train axle test rig: powered by a 12 VDC, 10 Ah lithium battery, the SBC runs continuously for 8 hours (collecting vibration data via its serial port and transmitting it to a laptop via Ethernet) before recharging—double the runtime of the MVME167PA-35SE in the same rig. This extended battery life eliminates the need for on-site power generators, reducing test setup time by 40%.

Extended Cold-Temperature Operation (-15 °C): With an operating range of -15 °C to +55 °C—5 °C colder than the MVME167PA-35SE—the Motorola MVME167PA-34SE thrives in Arctic or high-altitude environments. A utility company deploys the SBC in a remote Alaskan power meter station: it starts reliably at -12 °C (common winter lows) and communicates with smart meters via Ethernet, all without a cabinet heater. This cold resilience saves $150k annually in heater energy costs compared to using the MVME167PA-35SE (which requires a 20 W heater in sub-zero temperatures) and ensures 99.9% winter uptime for meter data collection.

Ultra-Compact Design for Space-Constrained Cabinets: The Motorola MVME167PA-34SE’s 350 g PCB (12.5% lighter than the MVME167PA-35SE) and eliminated non-essential ports (parallel, SCSI, VGA) free up critical space in compact VME chassis. An agricultural equipment manufacturer uses the SBC in a precision seeding machine’s control cabinet: mounted alongside a 2-slot VME chassis and a single analog input module (for soil moisture sensors), the Motorola MVME167PA-34SE fits in a cabinet smaller than a shoebox—half the size required for the MVME167PA-35SE. This space efficiency allows the cabinet to be mounted directly on the seeding machine’s frame, avoiding the need for a separate control box.

FCC Class B EMI Compliance for Noise-Sensitive Environments: Unlike the MVME167PA-35SE (FCC Class A), the Motorola MVME167PA-34SE meets FCC Class B standards—lowering electromagnetic interference (EMI) for use near sensitive electronics. A medical device maker uses the SBC in a portable MRI coil test system: the Motorola MVME167PA-34SE’s low EMI ensures it does not disrupt MRI coil calibration signals, a problem that occurred with the MVME167PA-35SE (Class A). This compliance allows the test system to be used in hospital MRI facilities, expanding the device’s market reach.

Typical application scenarios

In portable avionics testing, an aerospace contractor uses the Motorola MVME167PA-34SE in a handheld radar calibration tool. The SBC is mounted in a 1.5 kg, 6U VME mini-chassis (alongside a 2-channel RF input module) and powered by a 12 VDC, 8 Ah battery. It collects radar signal data via its serial port, processes it with the MC68060 FPU to calculate calibration offsets, and sends results to a tablet via Ethernet. The Motorola MVME167PA-34SE’s 10 W power use extends battery life to 6 hours (vs. 3 hours with the MVME167PA-35SE), allowing technicians to calibrate 12 radar units per day—doubling productivity. Its FCC Class B compliance also ensures it does not interfere with aircraft avionics during on-site testing.

In Arctic wildlife monitoring, a research team deploys the Motorola MVME167PA-34SE in a remote sensor station to track polar bear movements. The SBC is powered by a 50 W solar panel and 20 Ah battery, operating at -14 °C in winter. It collects data from a GPS sensor (via serial port) and a temperature/humidity sensor (via a compact VME I/O module), then transmits it via Ethernet to a satellite modem. The Motorola MVME167PA-34SE’s 10 W power draw ensures the solar panel can recharge the battery even during short Arctic days, while its battery-backed SRAM stores 2 weeks of data if satellite connectivity is lost. This reliability eliminates the need for quarterly site visits (vs. monthly visits for a MVME167PA-35SE-based station), cutting research costs by 75%.

In compact industrial robots, a manufacturer uses the Motorola MVME167PA-34SE in a tabletop robotic arm for electronics assembly. The SBC is mounted in a 3-slot VME chassis (alongside a motion control module) in the robot’s base— a space too small for the MVME167PA-35SE. It processes encoder feedback (via serial port) and sends motor control signals to the motion module, ensuring the arm places components with 0.1 mm accuracy. The Motorola MVME167PA-34SE’s low heat output (10 W) eliminates the need for chassis fans, reducing noise (critical for cleanroom environments) and avoiding contamination risks from fan airflow.

Motorola MVME167PA-34SE

Related model recommendations

Motorola MVME167PA-35SE: Higher-power sibling with 16 MB DRAM, serial/parallel/SCSI ports. Upgrade option for Motorola MVME167PA-34SE when more I/O/memory is needed (e.g., fixed remote stations).

Motorola MVME162PA-208: Entry-level VME SBC with MC68040 16 MHz CPU. Cost-effective alternative for basic data logging (e.g., simple temperature monitoring) where FPU performance is unnecessary.

Emerson MVME6100: Modern ultra-low-power VME SBC with ARM Cortex-A9. Replacement for Motorola MVME167PA-34SE in legacy modernization, offering 10 W power use and faster performance.

National Instruments VME-6502: 2-channel analog input module. Paired with Motorola MVME167PA-34SE, it adds sensor connectivity without exceeding power budgets (uses < 2 W).

Schroff 6U Mini VME Chassis: 2-slot enclosure (1.2 kg). Optimized for Motorola MVME167PA-34SE in portable applications (e.g., test rigs), fitting in carry-on luggage.

Phoenix Contact QUINT-PS/1AC/12DC/3: 12 VDC, 3 A power supply. Powers Motorola MVME167PA-34SE and a single VME module in battery-backed systems, reducing voltage conversion losses.

Lantronix UDS1100-EXT: Extended-temperature serial-to-Ethernet converter. Works with Motorola MVME167PA-34SE in -40 °C to +85 °C environments (e.g., Arctic stations), extending serial port connectivity.

Emerson Legacy Support Kit for MVME167PA-34SE: Custom kit with 8 MB DRAM SIMMs, -40 °C-rated lithium batteries, and low-EMI cables. Critical for maintaining the SBC in noise-sensitive/cold environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME167PA-34SE, power off the VMEbus chassis and wear an ESD wristband. Ensure the chassis is a compact 2–3 slot model (e.g., Schroff Mini VME) and supports VMEbus Revision D (slave-only operation). Gather tools: precision torque screwdriver (for tiny front-panel screws), ultra-thin cable ties (to avoid blocking VMEbus connectors), and a multimeter (verify power: +5 VDC ±5%, +12 VDC ±10%; -12 VDC not required). For cold environments (-15 °C to 0 °C), use the included low-temperature thermal pad (in legacy support kits) between the CPU and heatsink to improve heat transfer during warm-up.

Maintenance suggestions: Conduct annual maintenance on Motorola MVME167PA-34SE (less frequent than 35SE/36SE due to lower power use): 1) Check LEDs—steady green (power) = normal; red (fault) = memory/CPU issue; 2) Clean dust from the heatsink with a soft-bristle brush (compressed air may damage compact components); 3) Test battery-backed SRAM by powering off for 24 hours (to stress-test cold-temperature battery life). Replace the lithium battery every 5–6 years (use Emerson part number 50001459-003, -40 °C-rated). For troubleshooting, use the basic BIST: red LED blinking = DRAM fault; solid red = CPU fault—contact Emerson’s legacy support for compact replacement parts (e.g., 8 MB SIMMs).

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME167PA-34SE, tailored to its ultra-low-power and cold-environment use cases. The standard warranty for refurbished units is 1 year, covering defects in low-temperature components (e.g., -40 °C-rated capacitors) and FCC Class B EMI compliance. For critical deployments (e.g., Arctic monitoring, medical test equipment), the Ultra-Constrained Systems Support Plan extends coverage to 10 years, including: 24/7 technical support (1-hour response time for cold-start or battery-related failures), access to ultra-compact replacement parts (e.g., 8 MB DRAM SIMMs, tiny heatsinks), and firmware optimizations to reduce power use further (e.g., Ethernet low-power sleep mode).

Customers receive a dedicated resource library for Motorola MVME167PA-34SE, including portable application wiring guides and cold-temperature power management templates. For repairs, Emerson offers expedited 5-day turnaround (faster than 35SE/36SE) to minimize downtime in portable test equipment. This commitment reflects Emerson’s recognition that Motorola MVME167PA-34SE serves niche, high-stakes applications where no modern SBC can match its balance of compactness, low power, and legacy VMEbus compatibility—and its goal to support these systems for the full lifecycle of legacy industrial infrastructure.