Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | Motorola MVME2301-900 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

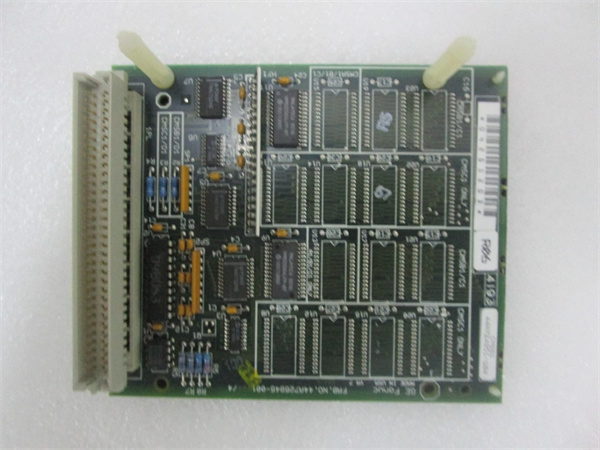

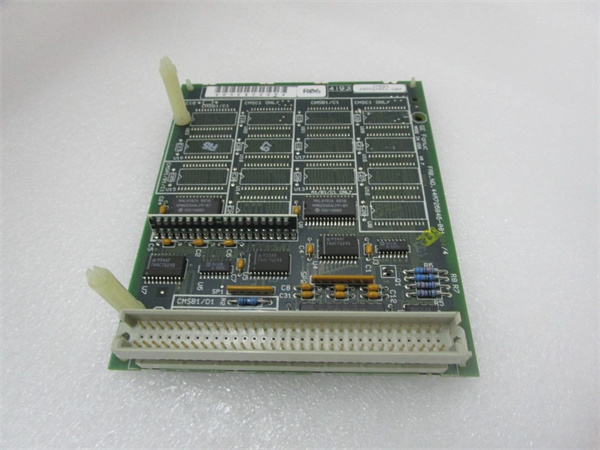

| Product category | Legacy Industrial VMEbus High-Speed Serial Communication Expansion Module |

| Serial Ports | 4x RS-232/RS-422/RS-485 ports (software-configurable per port); Supports synchronous (SDLC/HDLC) and asynchronous (UART) modes |

| Data Transfer Rate | Asynchronous: Up to 115.2 kbps; Synchronous: Up to 2 Mbps (HDLC/SDLC); Supports 7/8-bit data, 1/2 stop bits, even/odd/no parity |

| Isolation | Channel-to-channel galvanic isolation (2500V AC rms); Power isolation (1500V AC rms) – protects against ground loops and noise |

| Communication Interface | VMEbus A16/D16 slave (IEEE 1014-1987 compliant); Interrupt-driven data transfer (per port) with programmable interrupt priorities |

| Power Requirements | Input voltage: +5V DC (±5%) and +12V DC (±10%); Power consumption: Typical 4 W (25°C, all ports active); Maximum 6 W (synchronous mode, max speed) |

| Environmental Ratings | Operating temperature: -30°C–70°C (-22°F–158°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 50 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (industrial immunity), EN 61000-6-4 (industrial emissions) |

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 22mm (3.94in × 6.30in × 0.87in); Weight: 350 g (0.77 lbs) |

| Diagnostic Features | LED indicators (power, port activity, port fault, isolation status); Per-port self-test; Overcurrent protection (self-resetting polyfuses); Fault logging (non-volatile, 500+ events) |

| Compatible SBCs/Controllers | Motorola MVME2604, Motorola MVME-187, Motorola MVME-162PA-252SE, Motorola MVME-167-33A, Motorola MVME162-533 |

| Product Life Cycle | Discontinued/Obsolete |

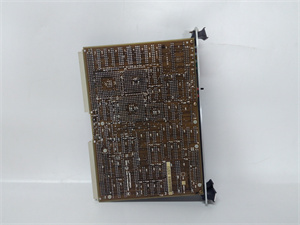

MOTOROLA MVME2301-900

Product Introduction

The Motorola MVME2301-900 is a legacy industrial VMEbus high-speed serial communication expansion module designed to add flexible, isolated serial connectivity to 2000s-era VME-based automation systems. Unlike basic serial modules (e.g., Motorola MVME340A with 2 non-isolated ports), Motorola MVME2301-900 delivers 4 configurable RS-232/422/485 ports, high-speed synchronous communication, and robust galvanic isolation—making it ideal for pairing with controllers like Motorola MVME2604 (compact embedded systems) or Motorola MVME-187 (high-performance SBCs) in applications requiring reliable long-distance or noise-prone serial communication.

As a dedicated serial expansion module in Motorola’s VME lineup, Motorola MVME2301-900 acts as a “serial connectivity hub.” It extends a system’s ability to connect to remote sensors, HMIs, or PLCs without overloading the host controller’s native ports. For example, in a 2000s oil and gas pipeline monitoring system, Motorola MVME2301-900 paired with Motorola MVME2604 to connect 4 remote pressure sensors via RS-485 (1 km distance)—its isolation preventing noise from pipeline pumps corrupting data. Today, Motorola MVME2301-900 remains critical for legacy systems where replacing it would require costly reconfiguration of serial-based sensor networks or custom driver development for modern modules.

Core Advantages and Technical Highlights

Multi-Protocol Serial Flexibility: Motorola MVME2301-900’s 4 software-configurable ports (RS-232/422/485) and support for synchronous/asynchronous modes adapt to diverse industrial needs. A 2000s manufacturing plant used Motorola MVME2301-900 with Motorola MVME-162PA-252SE: 2 ports as RS-485 (connecting 10 conveyor speed sensors, 500m distance), 1 port as RS-232 (local HMI), and 1 port as synchronous HDLC (linking to a central PLC). This flexibility eliminated the need for 3 separate modules, reducing VME chassis slot usage by 66% and simplifying wiring.

High Isolation for Noise-Prone Environments: With 2500V AC channel-to-channel isolation, Motorola MVME2301-900 outperforms non-isolated modules in harsh industrial settings. A 2000s steel mill used Motorola MVME2301-900 to connect temperature sensors near 480V rolling mills: its isolation prevented electrical noise from causing false temperature readings (which would have led to overheating steel batches). Non-isolated modules like Motorola MVME340A failed within 3 months in this environment, while Motorola MVME2301-900 operated reliably for 8+ years.

High-Speed Synchronous Communication: Unlike most serial modules of its era (limited to 115.2 kbps asynchronous), Motorola MVME2301-900 supports 2 Mbps synchronous HDLC/SDLC—critical for real-time data transfer. A 2000s telecommunications equipment test lab used Motorola MVME2301-900 with Motorola MVME-187 to stream test data from 4 network analyzers: the 2 Mbps synchronous link reduced data transfer time by 90% vs. asynchronous mode, enabling the lab to test 5x more devices per day. This speed also made it ideal for SCADA systems requiring fast remote I/O updates.

Typical Application Scenarios

In a 2000s municipal water distribution network, Motorola MVME2301-900 served as the serial expansion module for a Motorola MVME2604 controller at a central pump station. It used 3 RS-485 ports to connect 12 remote flow meters (2 km distance each) and 1 RS-232 port to a local HMI for operator monitoring. The module’s isolation protected against ground loops from the network’s distributed power supplies, while its 115.2 kbps asynchronous speed ensured flow data was updated every 2 seconds—critical for detecting leaks or pressure drops. Motorola MVME2301-900’s -30°C–70°C operating range withstood the station’s unheated outdoor cabinet (winter lows of -25°C) and summer highs of 65°C, ensuring uninterrupted water distribution to 50,000+ residents.

For a 2000s automotive assembly line’s robotic welding cell, Motorola MVME2301-900 paired with Motorola MVME-167-33A to coordinate 4 welding robots. It used 2 synchronous HDLC ports (2 Mbps) to send robot position commands and 2 RS-422 ports to receive weld quality sensor data. The high-speed synchronous link ensured commands reached robots with <10ms latency—preventing collisions—and isolation protected against electrical noise from welding transformers. Motorola MVME2301-900’s fault logging also recorded occasional sensor glitches, letting technicians schedule maintenance before failures disrupted production.

MOTOROLA MVME2301-900

Related Model Recommendations

Motorola MVME2604: Compact embedded controller – Primary pairing for Motorola MVME2301-900; Adds serial expansion to space-constrained systems (e.g., water pump stations).

Motorola MVME340A: Basic serial module – Alternative for Motorola MVME2301-900 users with non-critical, short-distance RS-232 needs (e.g., local HMI) to reduce costs.

Motorola MVME-187: High-performance SBC – Upgrade pairing for Motorola MVME2301-900; Handles high-volume serial data from synchronous ports (e.g., telecom test labs).

Motorola MVME177-004: Analog input module – Complements Motorola MVME2301-900; Adds analog sensing (e.g., pressure, temperature) to mixed-signal serial systems.

Emerson MVME2301-900-R: Refurbished variant – Tested to original isolation and speed specs; Critical replacement for failing Motorola MVME2301-900 units in legacy systems.

Motorola MVME-410: CANbus module – Pairs with Motorola MVME2301-900; Adds CANbus connectivity for systems needing both serial and vehicle/machinery communication (e.g., assembly lines).

Motorola 30GD-2-U4300117: Industrial PSU – Powers Motorola MVME2301-900 and host controllers, ensuring stable +5V/+12V for reliable isolation and serial operation.

Motorola MVME300: GPIB module – Expands systems using Motorola MVME2301-900; Adds GPIB support for test/measurement devices (e.g., lab equipment integration).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME2301-900, verify the VME chassis supports single-high 3U modules and A16/D16 addressing (compatible with hosts like Motorola MVME2604). Confirm the power supply provides +5V DC (±5%) and +12V DC (±10%) with <50mV ripple—use a precision multimeter to avoid voltage spikes that damage isolation circuits. Gather tools: anti-static wristband, torque screwdriver (0.3 N·m for 3U mounting), isolation tester (to validate 2500V AC isolation), and twisted-pair shielded cables (for RS-422/485 ports). For RS-485, terminate bus ends with 120Ω resistors and ground the cable shield to maximize noise immunity.

Maintenance suggestions: For daily upkeep, check Motorola MVME2301-900’s LEDs—steady power, blinking port activity, and no fault lights indicate normal operation. Run per-port self-test monthly via the host controller to validate isolation and communication; review fault logs quarterly to identify trends (e.g., recurring overcurrent on a specific port). Clean the module’s vents semi-annually with compressed air (15 PSI max) to prevent dust buildup. If a port fails, first check cables and termination resistors before replacing the module. Store spare Motorola MVME2301-900 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect isolation components.

Service and Guarantee Commitment

Motorola MVME2301-900 refurbished units are backed by a 24-month warranty from Emerson, covering defects in the serial transceivers, isolation circuits, VMEbus interface, and fault detection logic. If Motorola MVME2301-900 fails (e.g., in a water distribution network), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that risks service disruptions to thousands of users.

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with serial communication specialists), access to archived configuration software and isolation testing guides, and remote troubleshooting for synchronous/asynchronous mode setup. Emerson maintains a global stock of serial transceivers, isolation transformers, and polyfuses for Motorola MVME2301-900 until 2040, ensuring legacy serial-based industrial systems remain operational. This commitment underscores Emerson’s dedication to supporting reliable, long-distance communication in harsh automation environments.