Description

Detailed parameter table

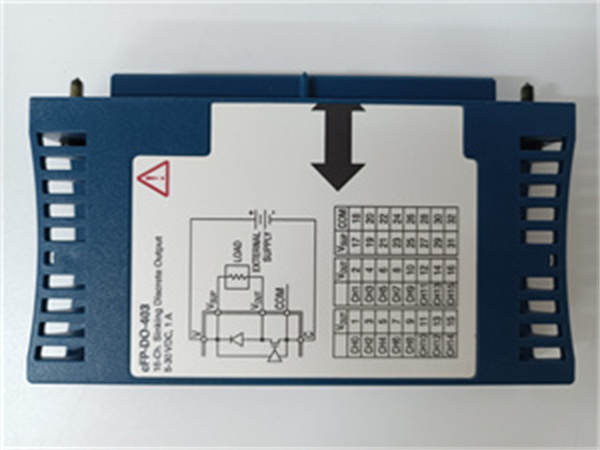

| Parameter name | Parameter value |

| Product model | NI CFP-DO-403 |

| Manufacturer | National Instruments (NI) |

| Product category | 8-Channel Relay Output Module (Compact FieldPoint) |

| Output Channels | 8 Form C (changeover) electromechanical relays |

| Switching Voltage | 250 VAC, 30 VDC |

| Switching Current | 2 A (resistive load); 1 A (inductive load) |

| Maximum Power Rating | 500 VA (AC), 60 W (DC) |

| Isolation Rating | 2500 Vrms (channel-to-channel, channel-to-chassis) |

| Operating Temperature Range | -40 °C to 70 °C |

| Storage Temperature Range | -55 °C to 85 °C |

| Chassis Compatibility | NI Compact FieldPoint chassis (NI CFP-1804, NI CFP-1808, NI CFP-1810) |

| Dimensions (L×W×H) | 81 mm × 140 mm × 41 mm |

| Relay Life | 100,000 operations (at maximum load); 10,000,000 operations (at 10% load) |

NI CFP-DO-403

Product introduction

The NI CFP-DO-403 is a robust 8-channel relay output module designed for NI’s Compact FieldPoint industrial automation platform, engineered to control high-power devices such as motors, valves, and heaters in harsh industrial environments. As a critical component of the Compact FieldPoint ecosystem, NI CFP-DO-403 serves as the bridge between low-voltage control systems and high-power field equipment, providing reliable switching capabilities with industrial-grade isolation.

Each channel of NI CFP-DO-403 features a Form C (changeover) relay, offering flexible wiring options (normally open, normally closed, or common) to accommodate diverse application needs. When paired with a NI CFP-1804 chassis and NI CFP-CB-1 connector block, NI CFP-DO-403 forms a rugged control system capable of operating in extreme temperatures (-40 °C to 70 °C) and high-vibration settings. Whether deployed in manufacturing, energy, or infrastructure applications, NI CFP-DO-403 delivers precise, durable switching to ensure safe and efficient operation of critical industrial equipment.

Core advantages and technical highlights

Industrial-grade isolation and safety: NI CFP-DO-403 features exceptional 2500 Vrms isolation between channels and the chassis, creating a critical safety barrier between low-voltage control signals and high-power field devices. This isolation protects sensitive automation systems from voltage transients and ground loops, which are common in industrial environments with multiple connected devices. For example, in a chemical plant controlling 240 VAC heating elements, this isolation prevents a heater short from damaging the Compact FieldPoint controller, enhancing system reliability and operator safety.

Flexible Form C relays for diverse loads: Unlike modules with only normally open (NO) relays, NI CFP-DO-403 uses Form C (changeover) relays, each providing NO, normally closed (NC), and common contacts. This flexibility allows the module to control both active and passive devices—from energizing a 24 VDC solenoid valve (via NO contacts) to monitoring a safety interlock (via NC contacts). In a water treatment plant, this means NI CFP-DO-403 can control a 120 VAC pump while simultaneously using the same relay’s NC contacts to trigger an alarm if power is lost, reducing the need for additional modules.

Rugged design for extended reliability: NI CFP-DO-403 is built to withstand the harshest industrial conditions, with an operating temperature range of -40 °C to 70 °C and resistance to vibration (5 g rms, 10-500 Hz) and shock (50 g peak). The relays themselves are rated for 100,000 operations at maximum load (2 A), ensuring long service life even in frequent-cycling applications like packaging machinery. This ruggedness minimizes unplanned downtime, a critical advantage in 24/7 industrial operations where maintenance windows are limited.

Typical application scenarios

In food and beverage processing, NI CFP-DO-403 controls 8 heating zones in a large oven used for baking. Mounted in a NI CFP-1808 chassis, the module uses its Form C relays to switch 240 VAC heating elements on/off based on temperature feedback from NI CFP-AI-100 modules. The NC contacts of each relay are wired to a central alarm system, triggering an alert if a heating zone fails to energize. NI CFP-DO-403’s -40 °C to 70 °C tolerance withstands the oven’s ambient heat, while its 2500 Vrms isolation protects the control system from electrical noise in the plant’s power grid.

In oil and gas production, NI CFP-DO-403 operates 8 valves in a pipeline manifold. The module, installed in an explosion-proof enclosure with a NI CFP-1810 chassis, uses its relays to control 24 VDC solenoid valves that regulate oil flow. The Form C contacts allow both valve actuation (NO) and position verification (NC), ensuring each valve responds correctly to commands. NI CFP-DO-403’s rugged design withstands vibration from nearby pumps and temperature swings in outdoor installations, providing reliable operation in a critical infrastructure application.

In manufacturing automation, NI CFP-DO-403 controls 8 conveyor section motors in an automotive parts assembly line. The module switches 480 VAC motor contactors via its relays, with NC contacts monitoring contactor status to detect failures. Paired with NI CFP-DI-304 digital input modules monitoring photoelectric sensors, NI CFP-DO-403 enables synchronized conveyor operation—starting/stopping sections based on part presence. Its fast switching (10 ms typical) ensures smooth material flow, reducing jams and improving production efficiency.

NI CFP-DO-403

Related model recommendations

NI CFP-DI-304: A 16-channel digital input module that complements NI CFP-DO-403 in control systems. While NI CFP-DO-403 triggers outputs, NI CFP-DI-304 monitors sensor inputs to inform those decisions.

NI CFP-1804: A 4-slot Compact FieldPoint chassis that hosts NI CFP-DO-403, providing power, communication, and ruggedization for industrial deployments.

NI CFP-CB-1: A 36-terminal connector block that simplifies wiring between field devices and NI CFP-DO-403, with secure screw terminals for high-power connections.

NI CFP-AI-100: An 8-channel analog input module that works with NI CFP-DO-403 in closed-loop control systems, providing feedback (e.g., temperature) to regulate relay outputs.

NI 9474: A C Series 8-channel relay output module, serving as a modern alternative to NI CFP-DO-403 in CompactRIO systems, with similar Form C relay functionality.

NI CFP-PWR-24: A 24 VDC power supply module that pairs with NI CFP-DO-403 to provide regulated power for solenoid valves and other DC field devices.

NI LabVIEW Real-Time: Software optimized for NI CFP-DO-403, enabling programmable logic control (PLC) functionality and sequence automation for relay operations.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI CFP-DO-403, power off the Compact FieldPoint chassis (e.g., NI CFP-1804) and use ESD protection (wrist strap, mat) to prevent damage. Verify the chassis has an available slot and that its firmware is updated via NI MAX. Gather tools: a Phillips-head screwdriver, wire strippers (for 18-14 AWG power wires), and torque screwdriver (set to 0.5 N·m for terminals). Connect NI CFP-CB-1 to NI CFP-DO-403 using the 37-pin D-sub connector, tightening thumbscrews to ensure a secure seal. Use shielded wiring for high-voltage connections, grounding shields at the chassis end to reduce noise. Mount the chassis in a location with adequate ventilation, away from direct heat sources, and within the module’s -40 °C to 70 °C range.

Maintenance suggestions: Inspect NI CFP-DO-403 connections quarterly via NI CFP-CB-1, checking for loose wires or signs of arcing (blackening) on terminals—tighten connections and replace damaged terminals if needed. Test relay functionality annually by cycling each channel under load and verifying both NO and NC contacts operate correctly; slow or inconsistent switching may indicate worn relays needing replacement. Monitor relay cycle counts via software to predict end-of-life and schedule maintenance during planned downtime. When replacing NI CFP-DO-403, label wires corresponding to NO, NC, and common contacts to simplify reconnection. Avoid exceeding the module’s voltage/current ratings, as this significantly reduces relay life.

Service and guarantee commitment

National Instruments backs NI CFP-DO-403 with a 2-year standard warranty, covering defects in materials and workmanship—including relay contacts, isolation components, and backplane connections. If NI CFP-DO-403 fails under normal use during the warranty period, NI provides free repair or replacement, with expedited service options for critical systems to minimize operational disruption.

NI’s global technical support team is available 24/7 to assist with module configuration, wiring diagrams, and troubleshooting relay performance issues. Customers receive lifetime access to driver updates, application notes, and relay maintenance guides for NI CFP-DO-403, ensuring optimal performance throughout the product’s lifecycle. This commitment reflects NI’s confidence in the module’s industrial-grade durability and its role as a reliable component in critical automation systems.