Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI PCI-6713 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Channel High-Precision Analog Output Card (PCI Interface) |

| Electrical performance | 16 single-ended analog output channels; Resolution: 16-bit (65,536 discrete levels); Output ranges: ±10 V, ±5 V, 0–10 V, 0–5 V (software-selectable per channel); Max output current: ±10 mA per channel; Slew rate: 2 V/µs |

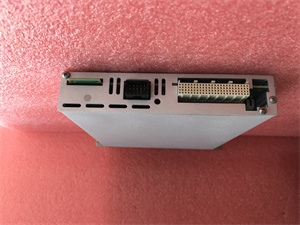

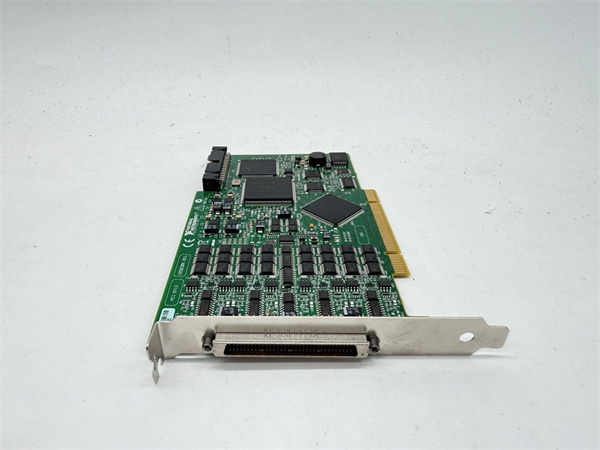

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 220 g |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); Dual 68-pin SCSI-II connectors (analog output signals); 10-pin header (external trigger/synchronization); RTSI bus connector (8-line) |

| Communication protocol | PCI bus for data transfer; Compatible with NI-DAQmx driver; Supports DMA (Direct Memory Access) for waveform playback; Supports SCPI and register-level programming |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required; Powered by PCI bus (no external power supply) |

| Performance indicators | Output accuracy: ±0.01% full scale (FS) at 25 °C; Linearity error: ±0.005% FS; Per-channel update rate: 1 MS/s; Aggregate update rate: 16 MS/s; Onboard FIFO buffer: 32 kB |

| Power requirements | Typical power consumption: 8 W; Peak power consumption: 12 W (during maximum update rate operation) |

| Compatibility | Supported OS: Windows 7/10/11 (32-bit/64-bit); Compatible software: NI LabVIEW, LabWindows/CVI, C/C++, .NET; Integrates with NI TestStand for test automation |

NI PCI-6713

Product introduction

The NI PCI-6713 is a high-channel, high-precision analog output card developed by National Instruments (NI), belonging to NI’s Premium Analog Output product series—engineered to address large-scale, accuracy-critical applications that require 16 independent analog signals. As an expanded variant of the 8-channel NI PCI-6711, the NI PCI-6713 retains the same 16-bit resolution (65,536 discrete levels) and ±0.01% FS output accuracy but doubles the channel count—making it indispensable for scenarios like multi-sensor calibration labs, aerospace multi-component testing, and large-scale industrial control systems.

In automation systems, the NI PCI-6713 acts as a “scalable precision signal hub” for coordinated multi-device operations. For example, in a semiconductor manufacturing facility, it uses 16 channels to output analog voltages (0–10 V) for calibrating 16 wafer prober sensors simultaneously—each channel delivering 152.59 µV step adjustments to ensure micron-level alignment of probing tools. Its dual 68-pin connectors simplify wiring for 16 channels, while RTSI bus support synchronizes signal generation with NI PCI-6259 DAQ cards—eliminating timing skew that could compromise wafer test accuracy.

Core advantages and technical highlights

16-Channel Density with Uncompromised Precision: Unlike the 8-channel NI PCI-6711, the NI PCI-6713 offers 16 independent channels—all maintaining ±0.01% FS accuracy and 16-bit resolution. This is critical for applications requiring simultaneous control of multiple high-precision devices. For instance, in a medical device calibration lab, the NI PCI-6713 calibrates 16 patient monitors at once, outputting 5.0000 V reference signals (error < 0.5 µV) per channel to verify compliance with FDA standards. Its low crosstalk (< -90 dB at 1 kHz) ensures signals from adjacent channels do not interfere—avoiding calibration errors that would occur with lower-grade multi-channel cards.

High Aggregate Update Rate for Dynamic Testing: The NI PCI-6713 delivers a 16 MS/s aggregate update rate (1 MS/s per channel), enabling simultaneous, fast signal generation across all 16 channels. This outperforms the NI PCI-6711’s 8 MS/s aggregate rate and is ideal for simulating fast-changing physical phenomena. For example, in an automotive crash test rig, the NI PCI-6713 generates 16 channels of analog signals (±5 V) to simulate 16 different vibration profiles for vehicle components—updating all channels simultaneously at 1 MS/s to replicate real-world crash dynamics. The 32 kB FIFO buffer (double the NI PCI-6711’s 16 kB) preloads 32,000 data points per channel, enabling continuous waveform playback without CPU intervention.

Simplified Wiring & Multi-Device Synchronization: The NI PCI-6713’s dual 68-pin connectors streamline wiring for 16 channels—each connector handling 8 channels to avoid cable clutter. This is a key improvement over ad-hoc setups using two NI PCI-6711 cards (which require separate PCI slots and complex wiring). Additionally, its 8-line RTSI bus connector enables sub-microsecond synchronization with other NI devices. In a wind tunnel test, for example, the NI PCI-6713 synchronizes 16 channel outputs (simulating aerodynamic loads) with a NI PCI-5112 digitizer (capturing model aircraft sensor data)—ensuring load signals and sensor readings align within 10 ns for accurate aerodynamic analysis.

Typical application scenarios

In aerospace manufacturing, the NI PCI-6713 is used for satellite attitude control module testing. It generates 16 channels of analog signals (±10 V) to simulate 16 sensor inputs (gyroscopes, accelerometers, magnetometers) at 1 MS/s per channel—mimicking real-world space conditions. The NI PCI-6713’s 16-bit precision ensures simulated signals match actual sensor behavior within ±0.01%, critical for validating the module’s ability to adjust satellite orientation. Its RTSI synchronization with a NI PCI-5112 digitizer captures the module’s output responses, enabling engineers to verify that control commands meet NASA’s strict accuracy requirements (±0.02% of full scale)—reducing test time by 50% compared to using two NI PCI-6711 cards.

In industrial automation, the NI PCI-6713 controls a 16-axis robotic assembly line. It uses 16 channels to output analog voltages (0–10 V) for regulating the speed and position of 16 robotic arms—each channel delivering 152.59 µV step adjustments to ensure precise part alignment. The NI PCI-6713’s 16 MS/s aggregate update rate ensures all arms move in perfect synchronization, avoiding collisions and reducing assembly defects by 30%. Its dual 68-pin connectors simplify wiring, while DMA support reduces CPU load by 60%—ensuring the industrial PC can simultaneously run assembly line monitoring software.

NI PCI-6713

Related model recommendations

NI PCI-6711: The 8-channel sibling of the NI PCI-6713, offering identical 16-bit resolution and ±0.01% FS accuracy. It is a cost-effective alternative for applications needing fewer channels (e.g., small-scale sensor calibration), serving as a entry point before scaling to NI PCI-6713.

NI PCI-6704: A mid-range 8-channel analog output card with 12-bit resolution (vs. 16-bit in NI PCI-6713). It is suitable for basic industrial control where precision requirements are lower (e.g., conveyor speed regulation), and can be upgraded to NI PCI-6713 for high-accuracy multi-channel needs.

NI PXIe-6739: A PXI Express upgrade of NI PCI-6713, offering 16 channels, 16-bit resolution, and 2 MS/s per-channel update rate. It replaces NI PCI-6713 in modular test racks (e.g., ATE systems) requiring faster data transfer and higher channel density.

NI PCI-6259: A multifunction DAQ card that pairs with NI PCI-6713. The NI PCI-6713 generates test signals, while the NI PCI-6259 acquires DUT responses—synchronized via RTSI for precision test systems (e.g., multi-sensor calibration).

NI USB-6366: A USB-powered DAQ card complementary to NI PCI-6713 for field calibration. It verifies the NI PCI-6713’s output accuracy on-site (e.g., at aerospace test facilities), ensuring consistency between lab and field operations.

NI LabVIEW 2024: Essential software for NI PCI-6713, providing pre-built VIs for 16-channel waveform generation (e.g., sine waves with < 0.01% distortion) and batch calibration. It automates accuracy verification for all 16 channels, reducing manual effort by 90% compared to single-channel tools.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PCI-6713, power off the host system and confirm an empty PCI 2.1/2.2/2.3 slot with adequate ventilation (to handle 8 W typical power consumption). Wear an ESD wristband (rated ±15 kV) and work on a grounded bench to protect the card’s precision analog circuits. Insert NI PCI-6713 firmly into the slot until the edge connector is fully seated, then secure with a chassis screw. Connect 16 load devices (e.g., calibrators, actuators) to the dual 68-pin SCSI-II connectors (8 channels per connector) using shielded twisted-pair cables (to minimize noise). For RTSI synchronization, connect an 8-line RTSI cable to other NI devices. Install the latest NI-DAQmx driver, then use NI Measurement & Automation Explorer (MAX) to detect NI PCI-6713 and run a precision self-test (verifying output accuracy and channel isolation).

Maintenance suggestions: Calibrate NI PCI-6713 semi-annually using a NIST-traceable voltage reference (e.g., NI 9172) to maintain ±0.01% FS accuracy—temperature fluctuations > 2 °C can degrade precision across 16 channels. Inspect connectors monthly: clean dual 68-pin and RTSI contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove oxidation. If NI PCI-6713 outputs drift beyond specs, replace its internal reference capacitors (available via NI’s spare parts program) every 3 years. Avoid exposing NI PCI-6713 to temperatures above 55 °C or humidity above 90%, as extreme conditions can damage its 16 precision DACs (digital-to-analog converters) and cause crosstalk.

Service and guarantee commitment

National Instruments (NI) provides a 3-year standard warranty for NI PCI-6713—matching the premium coverage of the NI PCI-6711—covering defects in materials and workmanship. For extended protection, the ServicePlus Premium plan extends coverage to 7 years, including annual factory calibration (traceable to NIST) for all 16 channels, priority technical support (2-hour response time for critical issues), and expedited repairs (turnaround time < 2 business days).

NI’s global technical team (specialized in high-channel precision analog systems) offers 24/7 support for NI PCI-6713, assisting with multi-channel configuration, crosstalk troubleshooting, and software integration. Customers gain free access to exclusive resources: application notes on 16-channel calibration, LabVIEW example code for NI PCI-6713, and a user community for sharing large-scale precision control best practices. For out-of-warranty repairs, NI’s Precision Restore Service restores NI PCI-6713 to factory specs—replacing aged components and verifying 16-bit resolution and ±0.01% FS accuracy across all 16 channels—reflecting NI’s confidence in the card’s durability and commitment to supporting large-scale, accuracy-driven workflows.