Description

Detailed parameter table

| Parameter name | Parameter value |

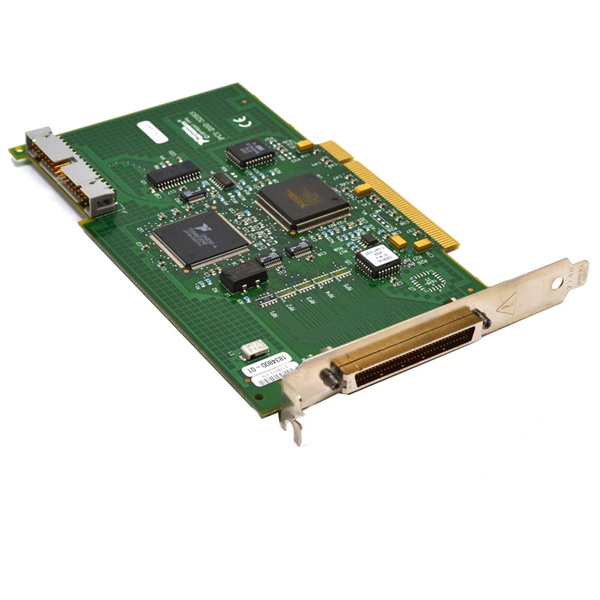

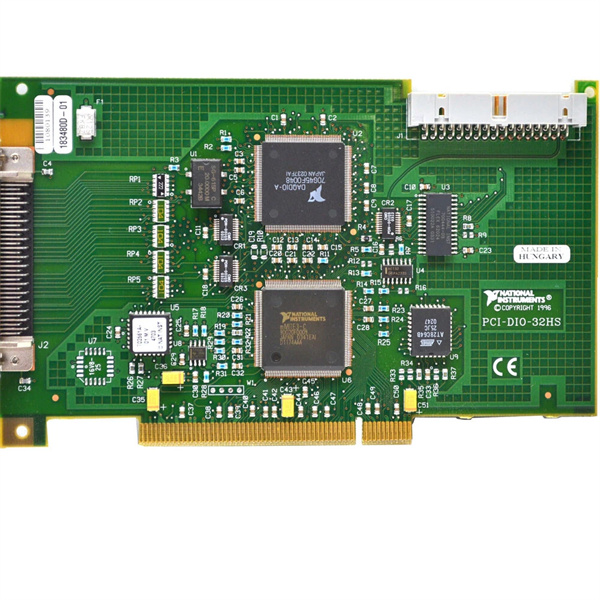

| Product model | NI PCI-DIO-32HS |

| Manufacturer | National Instruments (NI) |

| Product category | High-Speed Digital I/O Card (PCI Interface) |

| Electrical performance | 32 bidirectional digital I/O lines (configurable as input/output per line); Logic levels: 5 V TTL/CMOS; Sink/source current: 24 mA per line; Maximum switching frequency: 80 MHz; Pulse width generation: As low as 12.5 ns |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 200 g |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); Dual 68-pin SCSI-II connectors (for digital signal I/O); RTSI bus connector (8-line, for multi-device synchronization); 10-pin header (external trigger input) |

| Communication protocol | PCI bus for data transfer; Compatible with NI-DAQmx driver (primary) and Traditional NI-DAQ (legacy); Supports scatter-gather DMA (direct memory access) for high-throughput data; Supports register-level programming and SCPI |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required during installation; Powered by PCI bus (no external power supply) |

| Performance indicators | Data transfer rate: Up to 132 MB/s (PCI bus limit); Channel-to-channel skew: < 5 ns; Setup time: 10 ns; Hold time: 5 ns; Onboard FIFO buffer: 8 kB (for data preloading); Trigger modes: Edge (rising/falling), level (high/low) |

| Power requirements | Typical power consumption: 8 W (PCI bus); Peak power consumption: 12 W (during 80 MHz full-channel operation) |

| Compatibility | Supported OS: Windows 7/10/11 (32-bit/64-bit); Compatible software: NI LabVIEW (v2010+), LabWindows/CVI, C/C++, .NET, Python (via NI-DAQmx API); Integrates with NI TestStand for automated digital testing |

NI PCI-DIO-32HS

Product introduction

The NI PCI-DIO-32HS is a high-speed digital I/O card developed by National Instruments (NI), belonging to NI’s High-Speed Digital product series—engineered exclusively for fast, reliable digital signal generation and acquisition. Unlike multifunctional DAQ cards such as the NI PCI-DAS160216 (which splits resources between analog and digital tasks), the NI PCI-DIO-32HS is purpose-built for digital workflows: it delivers 32 configurable I/O lines operating at up to 80 MHz, making it indispensable for applications like high-speed pattern testing, real-time industrial control, and digital communication protocol validation.

In automation systems, the NI PCI-DIO-32HS acts as a “digital signal backbone” for high-throughput operations. For example, in a semiconductor chip test setup, it uses 16 lines to generate test patterns (80 MHz) for chip inputs and 16 lines to capture output responses—scatter-gather DMA ensures data is transferred to the host PC at 132 MB/s, eliminating bottlenecks that would slow down testing. Its RTSI bus support also synchronizes with NI PCI-6259 DAQ cards, enabling the NI PCI-DIO-32HS to trigger analog measurements at precise digital signal transitions—critical for validating mixed-signal chips.

Compared to the NI PCI-DAS160216’s digital I/O (limited to lower speeds), the NI PCI-DIO-32HS’s 80 MHz switching frequency and sub-5 ns channel skew ensure precise timing for time-sensitive tasks. This specialization makes it a top choice for industries like aerospace (digital avionics testing) and automotive (high-speed sensor data logging), where digital signal integrity directly impacts product performance.

Core advantages and technical highlights

80 MHz High-Speed Operation for Time-Sensitive Tasks: The NI PCI-DIO-32HS’s 80 MHz maximum switching frequency is 800× faster than the NI PCI-DAS160216’s typical digital I/O speed—enabling it to handle high-throughput digital workflows. For instance, in a high-speed data logging system for industrial sensors, the NI PCI-DIO-32HS captures 32 channels of digital sensor data at 80 MHz (80 million samples per second), ensuring no data loss during rapid sensor state changes (e.g., 12.5 ns pulse detection). This speed is critical for applications like engine control unit (ECU) testing, where digital signals from 32 sensors must be logged at microsecond intervals to analyze transient behavior.

32 Configurable I/O Lines with Flexible Triggering: The NI PCI-DIO-32HS offers 32 bidirectional lines (configurable per line as input or output), providing greater flexibility than the NI PCI-DAS160216’s fixed 8-input/8-output digital lines. Users can reconfigure lines on the fly via NI-DAQmx—for example, in a test bench for consumer electronics, 16 lines can be set to output (generating USB 2.0 test signals) and 16 lines to input (capturing device responses) during one test, then reconfigured to 24 input/8 output for HDMI protocol testing the next. Its versatile triggering (edge/level) also lets users start/stop I/O operations based on external events (e.g., a sensor’s “ready” signal), reducing unnecessary data capture and optimizing system efficiency.

Scatter-Gather DMA for Uninterrupted Data Transfer: Unlike the NI PCI-DAS160216’s basic DMA, the NI PCI-DIO-32HS uses scatter-gather DMA to transfer non-contiguous data blocks directly to/from system memory—reducing CPU load by 70% during high-speed operations. In a digital communication test setup, for example, the NI PCI-DIO-32HS generates 80 MHz Ethernet test frames (stored in non-contiguous memory buffers) and sends them to a device under test (DUT) via scatter-gather DMA. The CPU is free to analyze DUT responses in parallel, rather than managing data transfer—cutting test time by 40% compared to software-based data handling.

Sub-5 ns Channel Skew for Precise Timing Alignment: The NI PCI-DIO-32HS’s channel-to-channel skew of < 5 ns ensures all 32 digital lines switch in near-perfect synchronization—far better than the NI PCI-DAS160216’s typical 20+ ns skew. This is critical for applications like digital logic testing, where even small timing differences can cause false test results. For example, in a field-programmable gate array (FPGA) validation setup, the NI PCI-DIO-32HS sends 32 parallel test signals to the FPGA with < 5 ns skew, ensuring the FPGA receives all signals at the same time—validating its timing closure and preventing misdiagnosis of logic errors.

Typical application scenarios

In aerospace manufacturing, the NI PCI-DIO-32HS is used for digital avionics control system testing. A test rig uses the card’s 32 digital lines to simulate 32 avionics sensors (e.g., altitude, airspeed) at 80 MHz—generating fast transient signals to mimic in-flight conditions. The NI PCI-DIO-32HS’s scatter-gather DMA logs sensor data to the host PC at 132 MB/s, while its RTSI bus synchronizes with a NI PCI-6259 DAQ card to measure the control system’s analog output (e.g., actuator voltage). This setup validates the control system’s ability to respond to rapid sensor changes (e.g., a 100 µs altitude drop) within aerospace safety standards, with sub-5 ns skew ensuring sensor signals align correctly for realistic testing.

In automotive electronics, the NI PCI-DIO-32HS powers high-speed ECU (Electronic Control Unit) validation. An automotive test lab uses 16 lines of the NI PCI-DIO-32HS to generate CAN FD (Flexible Data-Rate) protocol signals (80 MHz) to the ECU, and 16 lines to capture the ECU’s digital feedback (e.g., fuel injection commands). The card’s 12.5 ns pulse width generation simulates faulty sensor signals (e.g., a 25 ns glitch in the crankshaft position sensor), testing the ECU’s error-handling capabilities. LabVIEW integration lets engineers automate 1,000+ test cases, with the NI PCI-DIO-32HS’s high speed reducing ECU validation time from 48 hours (with the NI PCI-DAS160216) to 8 hours—accelerating time-to-market for new vehicle models.

In academic research, the NI PCI-DIO-32HS supports high-speed digital logic experiments. A university’s electrical engineering lab uses the card to teach students about digital communication protocols (e.g., Ethernet, SPI). Students program the NI PCI-DIO-32HS via LabVIEW to generate 80 MHz SPI signals, then use the card’s input lines to capture and analyze the signals—learning about timing skew, data integrity, and protocol validation. The card’s 32 configurable lines let students experiment with different protocol configurations (e.g., 8-bit vs. 16-bit SPI frames), while its sub-5 ns skew provides hands-on experience with real-world digital signal challenges.

NI PCI-DIO-32HS

Related model recommendations

NI PCI-DAS160216: A multifunctional DAQ card complementary to the NI PCI-DIO-32HS. The NI PCI-DIO-32HS handles high-speed digital I/O, while the NI PCI-DAS160216 manages analog input/output and basic counters—ideal for mixed-signal test systems (e.g., semiconductor chip testing with both digital and analog components).

NI PCI-6534: A higher-speed digital I/O card and upgrade of the NI PCI-DIO-32HS, offering 100 MHz switching frequency and 32 lines. It replaces the NI PCI-DIO-32HS in ultra-fast applications (e.g., 10 Gbps Ethernet testing) requiring speeds beyond 80 MHz.

NI PCI-6601: A counter/timer card that enhances the NI PCI-DIO-32HS’s timing capabilities. The NI PCI-DIO-32HS generates digital signals, while the NI PCI-6601 (8×24-bit counters, 80 MHz) tracks signal frequency or measures pulse widths—suitable for applications like digital signal characterization.

NI PCI-6259: A multifunctional DAQ card that pairs with the NI PCI-DIO-32HS for mixed-signal testing. The NI PCI-DIO-32HS handles digital I/O, while the NI PCI-6259 (32 analog inputs, 1.25 MS/s) captures analog data—critical for validating mixed-signal devices (e.g., automotive ECUs with analog outputs).

NI LabVIEW 2024: Essential software for the NI PCI-DIO-32HS, providing a graphical programming environment for building high-speed digital applications. It includes pre-built VIs for pattern generation, data logging, and trigger configuration—reducing development time for the NI PCI-DIO-32HS.

NI TB-2707: A terminal block for the NI PCI-DIO-32HS, offering 68-pin SCSI-II connectivity and terminal screws for secure sensor/device wiring. It simplifies field installation and provides surge protection for the NI PCI-DIO-32HS’s digital lines.

NI DAQmx Driver: The core driver for the NI PCI-DIO-32HS, enabling communication between the card and software. It includes tools for configuring I/O lines, setting trigger modes, and optimizing DMA transfer—ensuring optimal performance of the NI PCI-DIO-32HS.

NI TestStand 2024: Automated test software that integrates with the NI PCI-DIO-32HS. It lets users create digital test sequences (e.g., ECU protocol testing) and generate reports—ideal for manufacturing quality control with the NI PCI-DIO-32HS.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PCI-DIO-32HS, power off the host PC and confirm an empty PCI 2.1/2.2/2.3 slot. Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the card’s high-speed digital circuits. Insert the NI PCI-DIO-32HS firmly into the slot until the edge connector is fully seated, then secure it with a chassis screw. Connect digital devices (e.g., sensors, test fixtures) to the dual 68-pin SCSI-II connectors using shielded twisted-pair cables (50 Ω impedance-matched) to minimize EMI interference. For RTSI synchronization with other NI devices (e.g., NI PCI-6259), connect an 8-line RTSI cable. Install the latest NI-DAQmx driver, then use NI Measurement & Automation Explorer (MAX) to detect the NI PCI-DIO-32HS and run a self-test (verifying digital I/O functionality, DMA transfer, and trigger response).

Maintenance suggestions: Calibrate the NI PCI-DIO-32HS annually using a NIST-traceable digital signal generator (e.g., NI 5412) to verify timing accuracy (sub-5 ns skew) and pulse width generation (12.5 ns). Inspect the dual 68-pin connectors quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or oxidation—dirty contacts can cause signal bounce, degrading high-speed performance. If the NI PCI-DIO-32HS experiences data transfer errors, check the PCI slot for dust (clean with compressed air) or update the NI-DAQmx driver to the latest version. Avoid exposing the card to temperatures above 55 °C or humidity above 90%—extreme conditions can degrade the card’s high-speed logic gates. Replace the card’s internal configuration battery (available via NI’s spare parts program) every 5 years to retain I/O line configurations during power outages.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PCI-DIO-32HS, covering defects in materials and workmanship—including high-speed digital circuits, DMA controllers, and RTSI synchronization functionality. For extended protection, the ServicePlus Premium Plan extends coverage to 5 years, including annual factory calibration (traceable to NIST standards) for timing accuracy and pulse generation, priority technical support (2-hour response time for high-speed I/O issues), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team includes specialists in high-speed digital systems, offering 24/7 support for the NI PCI-DIO-32HS—assisting with DMA optimization, trigger configuration, and troubleshooting (e.g., resolving signal skew or data loss). Customers gain free access to exclusive resources: application notes on 80 MHz digital pattern generation with the NI PCI-DIO-32HS, LabVIEW example code for high-speed data logging, and a user community where engineers share best practices for digital communication testing. For out-of-warranty repairs, NI offers a flat-rate service that restores the NI PCI-DIO-32HS to factory specifications—replacing aged high-speed components (e.g., clock oscillators) and verifying 80 MHz switching frequency and < 5 ns channel skew. This commitment reflects NI’s confidence in the NI PCI-DIO-32HS’s durability and its dedication to supporting speed-critical digital workflows in industrial, automotive, and research sectors.