Description

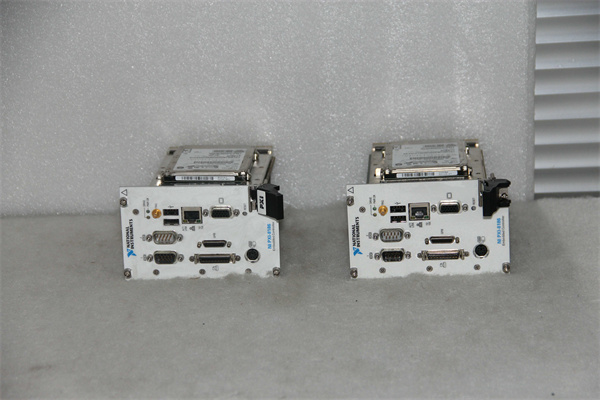

NI PXI-8186 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXI-8186 |

| Manufacturer | National Instruments |

| Product Category | PXI Controller |

| Form Factor | 3U PXI (system slot module) |

| Processor | Intel Core 2 Duo T7400 (2.16 GHz, 4 MB L2 cache) |

| Memory | Up to 4 GB DDR2 SDRAM (667 MHz) |

| Storage Options | 80 GB 2.5-inch SATA hard drive; optional 160 GB or solid-state drive (SSD) |

| Operating System Support | Windows XP Embedded, Windows 7 Professional (32-bit/64-bit) |

| PXI Bus Interface | PXI 2.2 compliant (32-bit/33 MHz PCI interface) |

| External I/O Ports | 2 x USB 2.0, 1 x GPIB (IEEE 488), 1 x RS-232, 1 x 10/100/1000 Base-T Ethernet, VGA |

| Expansion Slots | 1 x CompactFlash slot (Type II) |

| Power Consumption | Typical: 35 W; Maximum: 50 W |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 100 mm (width) x 160 mm (depth) x 37 mm (height) |

| Weight | 450 g |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Software Compatibility | LabVIEW, LabWindows/CVI, Measurement Studio, NI-DAQmx, NI Switch Executive |

NI PXI-8186

Product Introduction

The NI PXI-8186 is a high-performance 3U PXI controller designed to serve as the central processing unit for PXI test and measurement systems. As a key component in National Instruments’ PXI ecosystem, it combines a powerful Intel Core 2 Duo processor with robust I/O capabilities, enabling seamless control of PXI modules such as the PXI-6608 counter/timer, PXI-6527 digital I/O, and PXI-4462 dynamic signal acquisition module.

This controller is engineered to handle the computational demands of real-time data processing, automated test sequencing, and system synchronization. Its compact form factor fits into the system slot of PXI chassis like the PXI-1031, providing a integrated platform for building modular test systems. Whether deployed in aerospace validation labs, semiconductor manufacturing facilities, or industrial automation setups, the PXI-8186 delivers reliable performance for complex measurement and control tasks.

Core Advantages and Technical Highlights

Powerful Processing Capability

Equipped with an Intel Core 2 Duo T7400 processor (2.16 GHz) and up to 4 GB of DDR2 memory, the PXI-8186 excels at handling multi-threaded applications—critical for systems running simultaneous data acquisition, analysis, and control tasks. For example, in a automotive NVH test system, it can process vibration data from the PXI-4462 module while executing test sequences and logging results to storage, without performance degradation.

Versatile I/O Connectivity

The controller features a comprehensive set of external ports, including GPIB, Ethernet, USB, and RS-232, enabling seamless integration with external instruments, networked systems, and peripherals. The built-in GPIB interface eliminates the need for a separate GPIB-to-PXI adapter, simplifying connections to legacy instruments such as oscilloscopes or signal generators. The Gigabit Ethernet port supports high-speed data transfer to network storage or remote monitoring systems, enhancing system flexibility.

Robust Storage Options

With a standard 80 GB SATA hard drive (expandable to 160 GB or SSD), the PXI-8186 provides ample storage for test data, application software, and operating system files. SSD options offer faster data access and improved shock resistance, making them ideal for mobile test systems or environments with vibration. The CompactFlash slot allows for additional removable storage, facilitating data transfer between systems or backup of critical test configurations.

Seamless PXI Integration

As a PXI 2.2 compliant controller, the PXI-8186 leverages the PXI bus for low-latency communication with other modules in the chassis. It supports PXI trigger lines and the Star trigger, enabling precise synchronization with modules like the PXI-6608 for coordinated data acquisition and control. This integration ensures that all system components operate in lockstep, critical for time-sensitive applications such as radar testing or high-speed manufacturing inspection.

Typical Application Scenarios

Automated Test Systems

In electronics manufacturing, the PXI-8186 serves as the brain of automated test stations, controlling PXI modules to perform functional tests on PCBs or ICs. It coordinates the PXI-2510 switch module to route signals, the PXI-4071 DMM to take measurements, and the PXI-6527 to control test fixtures—all while executing test scripts and generating pass/fail reports. Its processing power enables rapid test sequence execution, maximizing production throughput.

Aerospace and Defense Data Acquisition

In aerospace testing, the controller manages multi-channel data acquisition systems using modules like the PXI-4462. It processes real-time vibration, acoustic, and pressure data from aircraft components under test, applying analysis algorithms to detect anomalies. The Ethernet port allows for remote monitoring of test progress by engineers, while the GPIB interface connects to external calibration equipment to ensure measurement accuracy.

Industrial Process Control

In industrial settings, the PXI-8186 integrates with PXI-6608 counter/timer and PXI-6527 digital I/O modules to control manufacturing processes. It executes closed-loop control algorithms based on sensor data, adjusting motor speeds, valve positions, or heating elements to maintain process parameters. The robust operating temperature range (0 °C to 55 °C) ensures reliable operation in factory environments with varying temperatures.

NI PXI-8186

Related Model Recommendations

NI PXI-1031: A 5-slot PXI chassis that houses the PXI-8186 controller and other modules, providing a compact platform for mid-sized test systems. For larger setups, the PXI-1042 (18-slot) offers expanded capacity.

NI PXI-6608: A counter/timer module synchronized with the PXI-8186 via PXI triggers, enabling precise timing of test events or control signals in coordinated systems.

NI PXI-4462: A dynamic signal acquisition module whose data is processed in real time by the PXI-8186, which applies signal analysis algorithms to vibration or acoustic data.

NI LabVIEW: Software used to develop custom applications for the PXI-8186, featuring graphical programming tools for designing test sequences, data analysis, and user interfaces.

NI PXI-8232: A PXI-to-GPIB interface module (if additional GPIB ports are needed) that works with the PXI-8186 to connect more external instruments beyond the controller’s built-in GPIB port.

Installation, Commissioning, and Maintenance

Installation Steps

Chassis Preparation: Power off the PXI chassis (e.g., PXI-1031) and ensure it is properly grounded. Locate the system slot (typically slot 1) in the chassis.

Controller Insertion: Align the PXI-8186 with the system slot guides, ensuring the connector at the rear of the module engages with the chassis backplane. Push firmly until the module is fully seated, then secure with front-panel screws.

Peripheral Connection: Connect external devices to the controller’s ports: GPIB instruments to the GPIB port, network cables to Ethernet, USB devices (e.g., keyboards, mice) to USB ports, and a monitor to the VGA port.

Power On: Power on the PXI chassis. The controller will boot to the installed operating system; follow on-screen prompts to complete initial setup (e.g., driver installation, network configuration).

Commissioning

System Detection: Launch NI Measurement & Automation Explorer (MAX) to verify that the controller recognizes all installed PXI modules (e.g., PXI-6608, PXI-4462). Update module drivers if necessary.

Performance Validation: Run a stress test application to verify the controller’s processing capability—for example, processing a large dataset from the PXI-4462 while executing a test sequence. Monitor CPU and memory usage to ensure no bottlenecks.

Synchronization Check: Use the PXI Star trigger to synchronize the controller with the PXI-6608 module. Validate that trigger signals are propagated correctly across the system, ensuring time-aligned operation of all modules.

Maintenance Tips

Software Updates: Regularly update the operating system, NI drivers, and application software to address security vulnerabilities and improve performance. Use NI Update Service to manage driver updates.

Storage Maintenance: Periodically defragment the hard drive (for HDDs) or trim the SSD to optimize storage performance. Back up critical data to external storage or network drives to prevent loss.

Thermal Management: Ensure the PXI chassis cooling system is functioning properly, with fans free of dust. Monitor controller temperature via MAX to avoid overheating, which can cause throttling or hardware damage.

Connector Care: Inspect external ports for damage or debris. Clean GPIB and USB connectors with compressed air if necessary, and ensure cables are securely fastened to prevent intermittent connections.

Service and Guarantee Commitment

The NI PXI-8186 is backed by a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ global technical support team provides 24/7 assistance for installation, troubleshooting, and software integration via phone, email, and online resources.

NI offers repair and calibration services for the controller, ensuring it meets original performance specifications. Extended warranty plans are available for customers requiring long-term support. With a focus on reliability, the PXI-8186 is engineered to deliver consistent performance in demanding PXI systems, backed by NI’s commitment to quality and customer success.