Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI PXIE-6556 |

| Manufacturer | National Instruments (NI) |

| Product category | PXIe High-Speed Digital I/O Module |

| Digital I/O Channels | 32 single-ended / 16 differential channels (configurable) |

| Maximum Data Rate | 100 MHz (per channel, synchronous operation) |

| Voltage Range | 1.8 V, 2.5 V, 3.3 V, 5 V (software-selectable per channel bank) |

| Timing Resolution | 10 ps (for precise edge placement in pattern generation) |

| Operating Temperature Range | -40 °C to 70 °C (extended industrial grade) |

| Storage Temperature Range | -40 °C to 85 °C |

| Connector Type | 68-pin VHDCI (Very High-Density Cable Interconnect) |

| Chassis Compatibility | NI PXIe chassis (e.g., PXIE-1082, PXIE-1085, PXIE-1095) |

| Power Consumption | 12 W (typical, from PXIe backplane) |

| Weight | 8.1 oz (230 g) |

| Key Functions | Pattern generation, pattern acquisition, edge detection, handshake I/O |

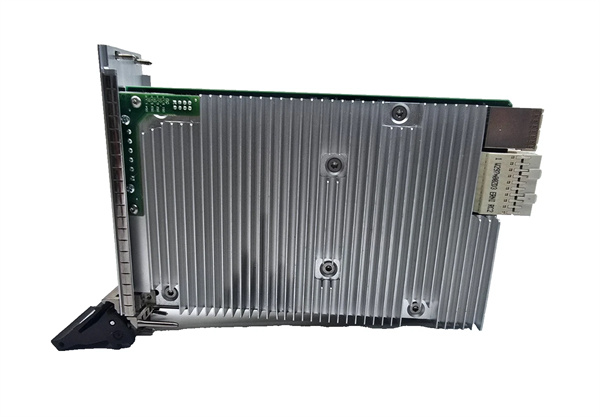

NI PXIE-6556

Product introduction

The National Instruments PXIE-6556 is a flagship PXIe high-speed digital I/O module, engineered to deliver ultra-fast, precise digital signal control for demanding test and automation applications. As a core component of NI’s PXIe modular platform, it bridges the gap between high-throughput data handling and flexible configuration—making it ideal for systems requiring synchronized digital communication with sensors, chips, or industrial components.

Designed for both pattern generation and acquisition, the NI PXIE-6556 supports 32 single-ended or 16 differential channels, with a maximum data rate of 100 MHz per channel. When paired with NI’s LabVIEW software or NI-DAQmx driver, the NI PXIE-6556 enables users to create custom test sequences, capture high-speed digital data, and integrate with other PXIe modules (e.g., analog I/O, timing modules) for end-to-end system synchronization. Its software-selectable voltage levels (1.8 V to 5 V) also ensure compatibility with a wide range of digital devices, from low-voltage semiconductors to industrial sensors.

Core advantages and technical highlights

High-Speed Performance for Throughput-Critical Applications:

The NI PXIE-6556 delivers a maximum data rate of 100 MHz per channel, enabling it to handle high-volume digital signal streams—such as those in semiconductor memory testing or high-speed industrial bus monitoring. Unlike slower digital I/O modules, the NI PXIE-6556 maintains synchronous operation across all channels, ensuring no data loss or timing skew even when generating/acquiring complex patterns (e.g., 100,000 digital states per second). This performance is critical for applications like automated test equipment (ATE) for microchips, where test speed directly impacts production efficiency.

Ultra-Precise Timing for Repeatable Results:

With 10 ps timing resolution, the NI PXIE-6556 offers unmatched precision for edge placement in pattern generation. This level of accuracy ensures that digital signals (e.g., clock pulses, trigger signals) align perfectly with device under test (DUT) requirements—reducing test variability and improving result repeatability. For example, in aerospace avionics testing, the NI PXIE-6556 can generate digital control signals with sub-nanosecond precision to simulate real-world flight conditions, ensuring avionics components respond correctly to time-critical commands.

Flexible Voltage and Channel Configuration:

The NI PXIE-6556 supports software-selectable voltage levels (1.8 V, 2.5 V, 3.3 V, 5 V) per channel bank, eliminating the need for external level shifters when testing devices with different voltage requirements. Additionally, its 32 single-ended/16 differential channel configuration adapts to both single-ended (e.g., TTL) and differential (e.g., LVDS) signal standards—making the NI PXIE-6556 a versatile solution for mixed-signal test setups. This flexibility reduces hardware complexity and lowers costs by replacing multiple single-voltage modules with one.

Typical application scenarios

In semiconductor manufacturing, the NI PXIE-6556 is a workhorse for memory chip testing. It generates high-speed read/write patterns (up to 100 MHz) to validate the performance of DRAM or flash memory modules, while simultaneously acquiring response signals to detect errors. Its 10 ps timing resolution ensures that test patterns match the strict timing specifications of modern memory chips, and its software-selectable voltages (1.8 V to 5 V) support testing across generations of memory technology—from legacy 5 V DDR1 to modern 1.8 V DDR5.

In aerospace and defense, the NI PXIE-6556 powers ATE systems for avionics digital interfaces (e.g., ARINC 429, MIL-STD-1553). It generates simulated digital commands to test avionics components (e.g., flight control units) and captures response data to verify compliance with military standards. The NI PXIE-6556’s extended temperature range (-40 °C to 70 °C) also makes it suitable for field-deployed test systems, where environmental conditions are harsh.

In industrial automation, the NI PXIE-6556 enables high-speed monitoring of industrial digital buses (e.g., Ethernet/IP, PROFINET). It acquires digital data from sensors and actuators at 100 MHz, allowing engineers to analyze transient events (e.g., unexpected sensor triggers) that slower modules might miss. When paired with NI’s LabVIEW, the NI PXIE-6556 also supports real-time data processing, enabling immediate adjustments to production lines to minimize downtime.

NI PXIE-6556

Related model recommendations

NI PXIE-6555: A sibling module in the same high-speed digital I/O series as the NI PXIE-6556, with 16 single-ended/8 differential channels (vs. 32/16 for the NI PXIE-6556). It’s a cost-effective option for smaller test setups where fewer channels are needed, while maintaining the same 100 MHz data rate and 10 ps timing resolution.

NI PXIE-6557: An upgraded model with 64 single-ended/32 differential channels—ideal for large-scale test systems (e.g., multi-DUT semiconductor testing) that require more channels than the NI PXIE-6556. It shares the same performance specs (100 MHz, 10 ps resolution) for seamless integration with the NI PXIE-6556 in mixed-channel setups.

NI PXIE-6674T: A PXIe timing and synchronization module that pairs with the NI PXIE-6556 to enhance system-wide timing. It provides precision clock signals to the NI PXIE-6556 and other PXIe modules (e.g., analog I/O), ensuring synchronized operation in complex test systems.

NI PXIE-1085: A 18-slot PXIe chassis designed to host the NI PXIE-6556. It offers high-bandwidth backplane connectivity (1 GB/s per slot) to support the NI PXIE-6556’s 100 MHz data rate, and includes built-in cooling for industrial environments.

NI PXIE-5122: A high-speed analog input module that complements the NI PXIE-6556 in mixed-signal test setups. While the NI PXIE-6556 handles digital signals, the NI PXIE-5122 acquires analog data (e.g., voltage waveforms) from DUTs, enabling comprehensive test coverage.

NI PXI-6556: The legacy PXI (non-Express) version of the NI PXIE-6556. It offers similar digital I/O capabilities but operates in PXI chassis (not PXIe), making it a replacement option for older systems that haven’t upgraded to PXIe.

NI SHC68-C68-S : A shielded cable accessory for the NI PXIE-6556, designed to connect the module’s 68-pin VHDCI connector to DUTs. It reduces electromagnetic interference (EMI) to maintain signal integrity at 100 MHz data rates.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PXIE-6556, verify that the target PXIe chassis (e.g., NI PXIE-1085) has an available slot and supports the module’s power requirements (12 W). Ensure the installation environment is free from excessive dust, moisture, or corrosive substances, and that the temperature stays within -40 °C to 70 °C. Required tools include a Phillips-head screwdriver (to secure the module to the chassis) and ESD protection gear (wrist strap, mat) to prevent electrostatic damage. Use only NI-approved shielded cables (e.g., NI SHC68-C68-S) for I/O connections—unshielded cables may introduce EMI and degrade signal quality at 100 MHz. Always power off the chassis before inserting the NI PXIE-6556 to avoid backplane damage.

Maintenance suggestions

For daily maintenance of the NI PXIE-6556, inspect the VHDCI connector monthly for corrosion, bent pins, or debris—clean with a dry, lint-free cloth if needed. Monitor the module’s status LEDs (power, fault, activity) via the chassis interface: a solid red fault LED indicates issues like overvoltage or channel overload, which require referencing the user manual for troubleshooting. Every 6 months, update the module’s firmware using NI Measurement & Automation Explorer (MAX) to access the latest stability and compatibility improvements. When replacing cables, ensure they are rated for high-speed signals (100 MHz+) to maintain performance. Avoid exposing the NI PXIE-6556 to extreme temperature fluctuations, as this can degrade timing precision over time.

Service and guarantee commitment

National Instruments (NI) backs the NI PXIE-6556 with a 2-year standard warranty, covering defects in materials and workmanship under normal use. If the NI PXIE-6556 fails during the warranty period, NI provides free repair or replacement, with expedited service options for critical applications (e.g., semiconductor production lines) to minimize downtime. NI’s global technical support team is available 24/7 via email, phone, and online chat, offering assistance with installation, LabVIEW integration, and troubleshooting complex timing issues. Additionally, NI provides lifetime access to firmware updates, driver downloads, and application notes for the NI PXIE-6556, ensuring the module remains compatible with new PXIe hardware and software. This commitment reflects NI’s confidence in the NI PXIE-6556’s reliability and ensures customers maximize their investment over the module’s long operational lifespan.