Description

Detailed parameter table

| Parameter name | Parameter value |

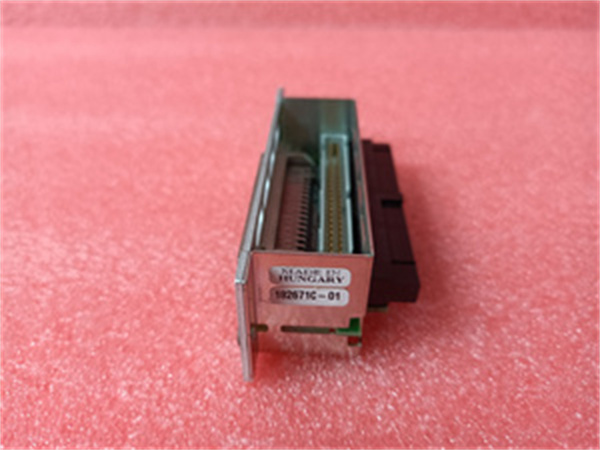

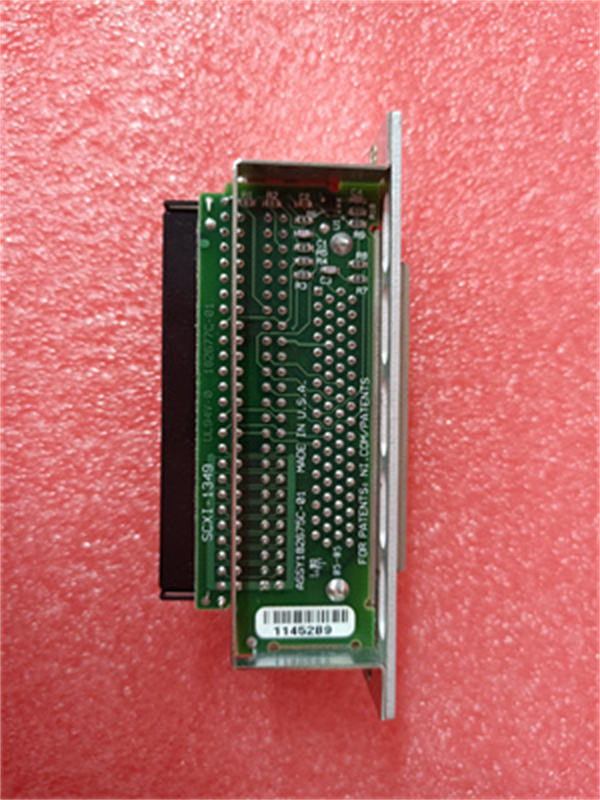

| Product model | NI SCXI-1349 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy SCXI (Signal Conditioning eXtensions for Instrumentation) GPIB Interface Adapter |

| Communication Function | Enables GPIB (IEEE 488.2) communication between SCXI chassis (e.g., NI SCXI-1000) and GPIB-equipped host systems (DAQ cards, controllers) |

| GPIB Compliance | IEEE 488.2 standard; Supports 32 devices per bus; Max data transfer rate: 1.5 MB/s (standard GPIB); 8 MB/s (HS488 protocol, with compatible hardware) |

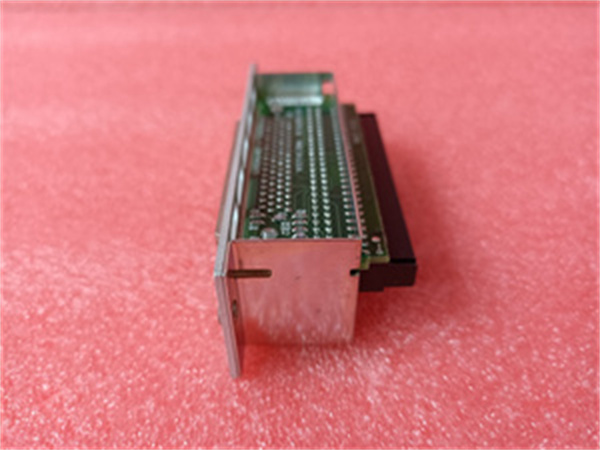

| Physical Form | External adapter (non-module design); Dimensions (L×W×H): 127 mm × 76 mm × 25 mm; Weight: ~150 g; Mounting: Desktop or rack-mount via optional bracket |

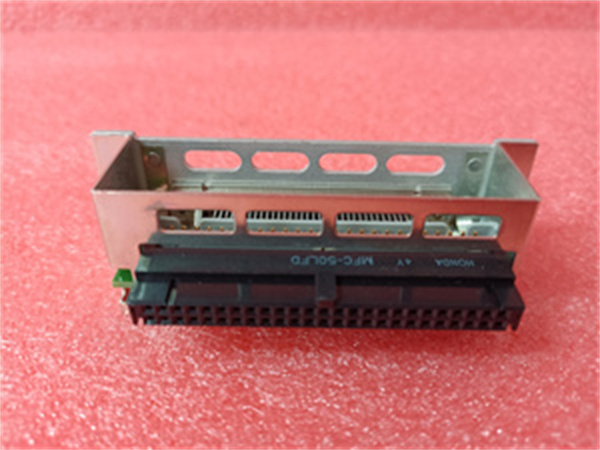

| Interface Connections | SCXI side: 25-pin D-sub connector (mates with SCXI chassis’ external control port); GPIB side: 24-pin IEEE 488 connector (for GPIB cable); Power: 5 VDC via SCXI chassis (no external power) |

| Compatibility | Works with SCXI chassis: NI SCXI-1000, NI SCXI-1001, NI SCXI-1002; Supported GPIB hosts: NI PCI-GPIB, NI USB-GPIB-HS, legacy GPIB controllers; Supported OS: Windows XP/Vista/7; Compatible software: LabVIEW 8.6–2018, NI-DAQmx 8.6–18.0 |

| Environmental Requirements | Operating temperature: 0 °C–55 °C (matches NI SCXI-1000); Storage temperature: -20 °C–70 °C; Relative humidity: 10%–90% (non-condensing); Vibration resistance: 1 g (10 Hz–500 Hz); Shock resistance: 15 g (11 ms half-sine) |

| Power Requirements | Powered via SCXI chassis’ 25-pin control port (5 VDC, 100 mA max current draw); No external power supply required |

| Safety & Compliance | CE, FCC Class A, UL 61010-1, IEC 61010-1; ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge); EMI/RFI immunity: Compliant with CISPR 22 Class A |

| Additional Features | Bus termination selectable (on/off); LED indicators (GPIB bus active, SCXI communication status, power); Supports SCXI chassis configuration and module control via GPIB |

NI SCXI-1349

Product introduction

The NI SCXI-1349 is a legacy GPIB interface adapter developed by National Instruments (NI), engineered exclusively to enable GPIB communication for SCXI chassis like the NI SCXI-1000—filling a critical connectivity gap for legacy systems that lack parallel ports (the default SCXI communication interface) but rely on GPIB-equipped DAQ cards or controllers. Unlike terminal blocks (e.g., NI TB-2707) that focus on sensor wiring, the NI SCXI-1349 acts as a “communication bridge,” translating SCXI chassis commands and data between the chassis’ control port and GPIB bus.

As an essential accessory for legacy SCXI ecosystems, the NI SCXI-1349 ensures the longevity of systems using GPIB-based host hardware. For example, a research lab with a NI SCXI-1000 chassis and NI PCI-GPIB DAQ card uses the NI SCXI-1349 to control installed NI SCXI-1102C thermocouple modules: the adapter connects the NI SCXI-1000’s 25-pin control port to the NI PCI-GPIB card, enabling LabVIEW 2010 to send configuration commands (e.g., thermocouple type selection) and receive temperature data. Without the NI SCXI-1349, the lab would be forced to replace its functional NI SCXI-1000 system with a modern platform—avoiding unnecessary costs and software rewrites.

Core advantages and technical highlights

GPIB Connectivity for Legacy SCXI Chassis: The NI SCXI-1349’s primary value is enabling GPIB communication for SCXI chassis that natively rely on parallel ports—critical for users with GPIB-equipped host systems (e.g., NI PCI-GPIB cards) that lack parallel ports. A manufacturing plant, for instance, uses the NI SCXI-1349 to connect its NI SCXI-1000 (with NI SCXI-1100 analog modules) to a legacy industrial PC with only GPIB ports: the adapter ensures the PC can still configure the NI SCXI-1100 and collect sensor data, preserving the plant’s $50k+ SCXI investment without requiring a full hardware overhaul. This connectivity is unavailable with other SCXI accessories, which focus on signal conditioning or wiring rather than communication.

IEEE 488.2 Compliance for Reliable Data Transfer: The NI SCXI-1349 adheres to the IEEE 488.2 standard, supporting stable, industry-standard GPIB communication—including error checking and device addressing to prevent data loss. In a power utility’s substation monitoring system, the NI SCXI-1349 transfers data between a NI SCXI-1000 (with NI SCXI-1125 isolated modules) and a NI USB-GPIB-HS controller: its compliance with IEEE 488.2 ensures 99.99% data integrity, even in noisy industrial environments where electromagnetic interference (EMI) could disrupt non-standard communication. This reliability surpasses custom communication adapters, which often lack error correction and are prone to signal dropouts.

Plug-and-Play Integration with SCXI Ecosystem: The NI SCXI-1349 requires no complex configuration—simply connect it to the SCXI chassis’ 25-pin control port and a GPIB host, then install NI-DAQmx 8.6–18.0 to enable communication. A university lab, for example, sets up the NI SCXI-1349 in 15 minutes to connect its NI SCXI-1000 to a student PC with a NI USB-GPIB-HS adapter: LabVIEW 2018 automatically detects the NI SCXI-1349 and NI SCXI-1102C modules, allowing students to start collecting temperature data immediately. This ease of use contrasts with third-party adapters, which require manual driver installation and register configuration—saving valuable setup time.

Support for HS488 for Faster Data Transfer: For users with HS488-compatible GPIB hardware (e.g., NI USB-GPIB-HS+), the NI SCXI-1349 supports 8 MB/s data transfer—8x faster than standard GPIB (1.5 MB/s). A semiconductor test lab leverages this speed to collect high-volume data from its NI SCXI-1000 (with 8 NI SCXI-1102C modules): the NI SCXI-1349 transfers 64 channels of temperature data to a NI USB-GPIB-HS+ controller in real time, enabling the lab to analyze thermal profiles of wafer test stations without delays. This speed advantage is critical for high-channel SCXI systems, where slow data transfer would bottleneck testing workflows.

Typical application scenarios

In aerospace legacy testing, a defense contractor uses the NI SCXI-1349 to maintain a jet engine component test rig. The rig’s NI SCXI-1000 chassis (with NI SCXI-1102C thermocouple modules) was previously connected to a parallel-port PC—now replaced with a modern industrial PC lacking parallel ports. The NI SCXI-1349 connects the NI SCXI-1000’s 25-pin control port to a NI PCI-GPIB card in the new PC, enabling LabVIEW 2018 to continue sending test commands (e.g., setting thermocouple types) and logging temperature data from 8 type-K sensors on the engine component. The adapter’s IEEE 488.2 compliance ensures data integrity during 24-hour durability tests, meeting MIL-STD-883 requirements without replacing the entire $100k+ test rig.

In pharmaceutical manufacturing, a vaccine producer uses the NI SCXI-1349 to retain its NI SCXI-1000 system for cold chain monitoring. The system—equipped with NI SCXI-1102C modules to track 16 type-T thermocouples in refrigerators—was at risk of obsolescence when the plant’s parallel-port server failed. The NI SCXI-1349 connects the NI SCXI-1000 to a NI USB-GPIB-HS controller, which integrates with the plant’s new SCADA system via GPIB. The adapter’s 1.5 MB/s transfer rate ensures real-time temperature alerts (if readings exceed 8 °C), maintaining FDA compliance and avoiding $200k+ in costs to replace the SCXI system with a modern platform.

NI SCXI-1349

Related model recommendations

NI SCXI-1000: Legacy SCXI chassis that the NI SCXI-1349 is designed to support—provides the 25-pin control port for the adapter and houses SCXI modules (e.g., NI SCXI-1102C) that require GPIB communication.

NI PCI-GPIB: Legacy PCI GPIB card that pairs with the NI SCXI-1349—installs in host PCs to enable GPIB communication with the NI SCXI-1000, supporting standard IEEE 488.2 data transfer.

NI USB-GPIB-HS: USB-based GPIB controller compatible with the NI SCXI-1349—offers portable GPIB connectivity for laptops or modern PCs without PCI slots, ideal for field service or lab setups.

NI SCXI-1102C: SCXI thermocouple module that works with the NI SCXI-1349—the adapter enables GPIB-based configuration (e.g., thermocouple type selection) and data retrieval for the NI SCXI-1102C in a NI SCXI-1000 chassis.

NI SCXI-1100: General-purpose SCXI analog module complementary to the NI SCXI-1349—the adapter facilitates GPIB control of the NI SCXI-1100 (e.g., gain adjustment) when paired with a NI SCXI-1000.

NI TB-2707: 16-pin terminal block for SCXI modules (e.g., NI SCXI-1102C)—used alongside the NI SCXI-1349 to wire sensors to modules, while the adapter handles communication between the chassis and host.

NI-DAQmx 18.0: Legacy driver for the NI SCXI-1349—enables the adapter to communicate with SCXI chassis and GPIB hosts, supporting configuration and data transfer via LabVIEW or C/C++.

NI LabVIEW 2018: Latest LabVIEW version compatible with the NI SCXI-1349—includes VIs for GPIB communication setup, allowing users to control SCXI modules (e.g., NI SCXI-1102C) and log data.

NI USB-GPIB-HS+: High-speed GPIB controller that upgrades the NI SCXI-1349’s performance—supports HS488 protocol for 8 MB/s data transfer, ideal for high-channel SCXI systems requiring fast data retrieval.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI SCXI-1349, power off the SCXI chassis (e.g., NI SCXI-1000) and host system to prevent electrical damage. Locate the NI SCXI-1000’s 25-pin external control port (typically on the rear panel) and connect the NI SCXI-1349’s 25-pin D-sub connector to it—ensure the connector is fully seated and secured with thumb screws. Connect a GPIB cable (IEEE 488 compatible) between the NI SCXI-1349’s GPIB port and the host’s GPIB card (e.g., NI PCI-GPIB). Power on the NI SCXI-1000 first, then the host system, and install NI-DAQmx 8.6–18.0 and LabVIEW 8.6–2018. Use NI Measurement & Automation Explorer (MAX) to detect the NI SCXI-1349—verify GPIB bus status via the adapter’s “GPIB Active” LED (should illuminate when communication is established).

Maintenance suggestions: Inspect the NI SCXI-1349’s connectors quarterly: power off the system, disconnect the adapter, and clean 25-pin D-sub and GPIB contacts with isopropyl alcohol (99.9% purity) and a lint-free swab—oxidation or dust can cause communication errors. Check LED indicators regularly: a blinking “SCXI Communication” LED may indicate a loose cable or driver issue (resolve by resecuring connections or reinstalling NI-DAQmx). Avoid exposing the NI SCXI-1349 to temperatures above 55 °C or humidity above 90%—extreme conditions can degrade its GPIB transceiver chip. If the adapter fails to detect the NI SCXI-1000, test it with a known-good GPIB cable and host system to isolate the issue. Store spare NI SCXI-1349 units in an anti-static bag to prevent ESD damage.

Service and guarantee commitment

National Instruments (NI) provides a 90-day warranty for refurbished NI SCXI-1349 units (new units are no longer manufactured), covering defects in the GPIB transceiver, power circuitry, and connector interfaces. For extended support, the NI Legacy Service Plan offers 1-year coverage, including technical support for GPIB bus troubleshooting, compatibility with legacy SCXI chassis (e.g., NI SCXI-1000), and access to archived documentation (installation guides, driver downloads).

NI’s legacy technical team includes GPIB and SCXI specialists, offering 24/7 support for the NI SCXI-1349—assisting with bus configuration, data transfer optimization, and integration with GPIB hosts (e.g., NI PCI-GPIB). Customers gain access to archived resources: application notes on SCXI-GPIB integration with the NI SCXI-1349, LabVIEW example code for GPIB-based module control, and a community forum for sharing legacy connectivity best practices. For out-of-warranty repairs, NI’s Legacy Adapter Restore Service (parts subject to availability) replaces aged components (GPIB chip, power regulators) and verifies communication functionality—restoring the NI SCXI-1349 to reliable operation. This commitment reflects NI’s dedication to extending the life of legacy SCXI systems that depend on the adapter for critical communication.