Description

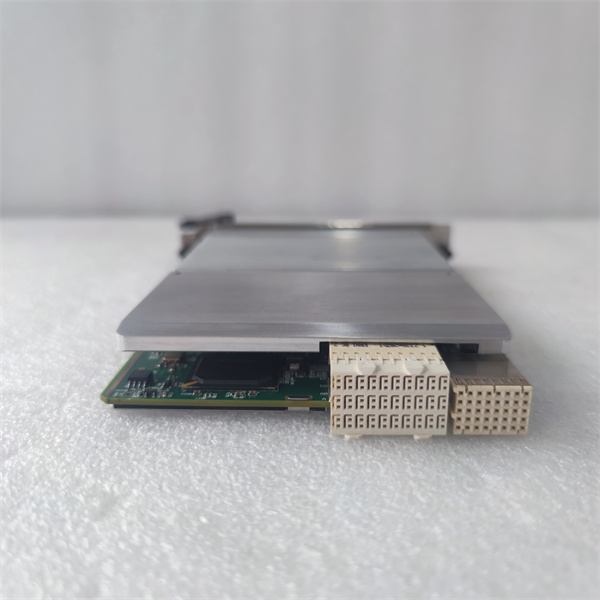

NI PXIE – 4142 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXIE-4142 |

| Manufacturer | National Instruments (NI) |

| Product category | Programmable DC power supply module |

| Output voltage range | 0 – 20 V |

| Output current range | 0 – 12 A |

| Power output | 240 W maximum |

| Voltage resolution | 0.1 mV |

| Current resolution | 1 mA |

| Programming interface | PXI Express, LAN, USB |

| Accuracy | Voltage accuracy: ±0.02% of reading + 0.02% of range; Current accuracy: ±0.05% of reading + 0.05% of range |

| Operating temperature | 0 °C – 55 °C |

| Storage temperature | – 40 °C – 70 °C |

| Dimensions | 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H) |

NI PXIE-4142

Product introduction

The NI PXIE-4142 is a sophisticated programmable DC power supply module from National Instruments (NI), a trusted name in test, measurement, and automation. As part of the PXI Express (PXle) platform, it’s crafted to offer precise and adaptable power supply solutions for diverse applications.

With an output voltage range of 0 – 20 V and a substantial output current range of 0 – 12 A, reaching a maximum power output of 240 W, the NI PXIE-4142 caters to power – hungry devices and circuits. Its remarkable voltage resolution of 0.1 mV and current resolution of 1 mA ensure meticulous power adjustments. The multiple programming interfaces—PXI Express, LAN, and USB—grant users the flexibility to integrate it into various systems, whether it’s for powering equipment in a bustling industrial production line, testing components in a high – tech electronics lab, or enabling automated test setups.

Core advantages and technical highlights

Ultra – precise Power Regulation: The NI PXIE-4142 excels in delivering highly accurate power outputs. Its voltage accuracy of ±0.02% of reading + 0.02% of range and current accuracy of ±0.05% of reading + 0.05% of range make it a top choice for applications where stable and precise power is non – negotiable. In lithium – ion battery testing, for example, the exact control over voltage and current is essential to accurately assess battery performance and safety, and the PXIE-4142 rises to the occasion, ensuring reliable test results.

Versatile and Convenient Programming: Thanks to its PXI Express, LAN, and USB programming interfaces, the PXIE-4142 offers unparalleled flexibility. In large – scale automated test systems, it can be seamlessly integrated via PXI Express for efficient control. Meanwhile, the LAN and USB interfaces allow engineers to remotely configure and monitor the power supply, which is incredibly useful in scenarios where the equipment is located in hard – to – reach areas or when multiple power supplies need to be managed simultaneously. This versatility streamlines the workflow and boosts productivity.

High – power Delivery with Efficiency: Designed to handle high – power demands, the NI PXIE-4142 provides a robust 240 W output while maintaining good power efficiency. It minimizes power losses during operation, reducing heat generation and ensuring stable performance even during extended use. This makes it suitable for industrial applications where continuous power supply is crucial, such as powering motors in automated manufacturing equipment or high – current electronic devices, without the worry of overheating or power – related disruptions.

Compact and Space – saving Design: Despite its high – power capabilities, the PXIE-4142 features a compact form factor with dimensions of 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H). This allows it to fit easily into PXI Express chassis, even in setups with limited space. Whether it’s part of a compact benchtop test system or integrated into a large – scale rack – mounted industrial control system, its compact design doesn’t compromise on performance, enabling the creation of dense, multi – functional power – supply solutions.

NI PXIE-4142

Typical application scenarios

In the electronics manufacturing industry, the NI PXIE-4142 is invaluable for testing power – intensive components like power amplifiers and high – current integrated circuits. During the production of these components, it supplies precise power, helping engineers detect any performance issues early in the process. Its accuracy ensures that components are tested under consistent conditions, improving the overall quality of the final products and reducing the likelihood of failures in the field.

In battery research and development laboratories, the PXIE-4142 plays a key role. It can be used to charge and discharge batteries under various conditions, simulating real – world usage scenarios. The precise control over voltage and current allows researchers to study battery behavior in detail, optimize battery performance, and develop new battery chemistries. The ability to remotely program and monitor the power supply also makes it convenient for running long – term battery tests without constant manual intervention.

For automotive electronics testing, the NI PXIE-4142 is essential. It can simulate the electrical power conditions that automotive components, such as electric vehicle drivetrains and onboard charging systems, will encounter during operation. By precisely regulating the power supply, engineers can assess the reliability and performance of these components under different scenarios, ensuring they meet strict safety and quality standards before being installed in vehicles.

Related model recommendations

- NI PXIE-4145: This model offers a higher voltage range of 0 – 60 V but a lower current range of 0 – 3 A compared to the PXIE-4142. It’s suitable for applications that require higher voltage but less current, such as powering certain types of high – voltage sensors or testing high – voltage electronic circuits. When combined with the PXIE-4142in a system, they can cover a broader spectrum of power requirements for different components.

- NI PXIE-4130: With a maximum power output of 60 W, the PXIE-4130is a lower – power option. It’s ideal for powering small – scale electronic devices, prototypes, or low – power sensors. It shares the same programming interfaces as the PXIE-4142, making it easy to integrate into systems where a combination of low – power and high – power supplies is needed, like in mixed – component test setups.

- NI PXIE-4155: Offering a higher power output of 300 W and an extended voltage range of 0 – 120 V, the PXIE-4155is designed for the most demanding applications. It can handle high – voltage and high – power loads, such as powering large – scale industrial equipment or conducting high – power component stress testing. For projects that may outgrow the capabilities of the PXIE-4142 in terms of power requirements, the PXIE-4155 serves as an upgrade option.

- NI PXIe – 4139: Focused on high – channel – density applications, the PXIe – 4139provides multiple isolated power outputs. It’s great for complex test systems where multiple independent circuits or devices need to be powered simultaneously. When used alongside the PXIE-4142, it can enhance the power – supply capabilities of a system, enabling more comprehensive and efficient testing of multi – component setups.

- NI PXIe – 4141: This module features enhanced programming response times and advanced power – sequencing capabilities. It’s well – suited for applications that demand quick and precise control over the power supply, such as high – speed electronic device testing or systems with complex power – on/off sequences. In scenarios where the PXIE-4142‘s standard programming capabilities aren’t sufficient for rapid or intricate power management, the PXIe – 4141can complement it to meet more specific requirements.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXIE-4142, make sure the PXI Express chassis is powered off and properly grounded. Check the chassis’s compatibility with the PXIE-4142 regarding slot type and available power resources. Take proper electrostatic – discharge (ESD) precautions, like wearing an ESD wrist strap, to protect the module during handling. Insert the PXIE-4142 into the chassis, carefully aligning it with the PXI Express slot and pushing it in until it clicks securely. Connect all necessary cables, including power cables and communication cables for programming (such as Ethernet for LAN or USB cables), following the wiring diagrams in the product manual precisely.

Maintenance suggestions: Regularly check the status indicators on the PXIE-4142 to monitor its operation. Clean the ventilation openings of the module and the PXI Express chassis regularly to prevent dust accumulation, which can impede heat dissipation and affect performance. Periodically calibrate the PXIE-4142 using NI – recommended calibration procedures and equipment to maintain its accuracy over time. Keep the module’s firmware updated as new versions are released to take advantage of performance improvements, bug fixes, and additional features. If you notice any abnormal behavior, such as inconsistent power output, communication glitches, or unexpected shutdowns, first check the cable connections, power supply, and configuration settings. If the problem persists, refer to the troubleshooting guide in the product manual. When replacing components, always use genuine NI parts to ensure the module’s reliability and performance.

Service and guarantee commitment

We have complete confidence in the quality and reliability of the NI PXIE-4142. The product is backed by a comprehensive warranty that covers all manufacturing defects. During the warranty period, if the PXIE-4142 fails to perform as specified, we will repair or replace it free of charge. Our dedicated technical support team is available 24/7 to assist you with installation, commissioning, and any technical issues you may encounter. We offer a wealth of online resources, including detailed user manuals, software drivers, and application notes, to help you maximize the potential of the PXIE-4142. Additionally, we are committed to continuous product improvement and regularly release firmware updates and technical enhancements to ensure that the PXIE-4142 remains at the forefront of programmable DC power supply technology, providing you with reliable and high – performing solutions for all your test, measurement, and automation needs.