Description

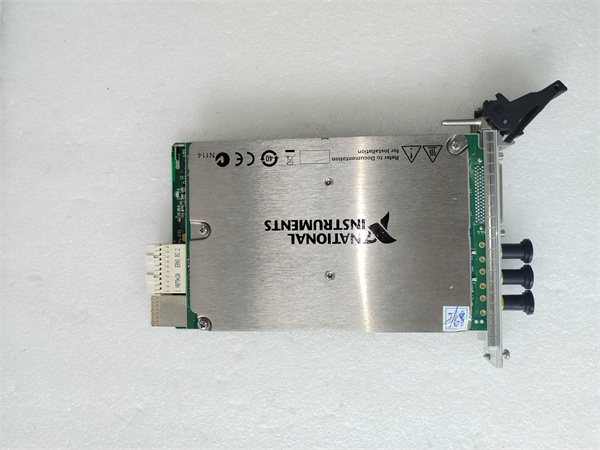

NI PXLE – 6544 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXLE-6544 |

| Manufacturer | National Instruments (NI) |

| Product category | High – speed digital I/O module |

| Digital I/O channels | 64 bidirectional channels |

| Maximum data transfer rate | Up to 800 MB/s |

| Signal levels | Supports LVTTL (Low – Voltage Transistor – Transistor Logic) and LVDS (Low – Voltage Differential Signaling) |

| Isolation | Optional channel – to – channel isolation up to 500 V rms |

| Triggering modes | Multiple triggering modes including edge – triggered, level – triggered, and software – triggered |

| PXI Express interface | x8 Gen 2 PXI Express interface for high – speed data transfer |

| Dimensions | 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H) |

| Power consumption | 18 W typical |

| Operating temperature | 0 °C to 55 °C |

| Storage temperature | – 40 °C to 70 °C |

NI PXLE-6544

Product introduction

The NI PXLE-6544 is a cutting – edge high – speed digital I/O module from National Instruments (NI), a leader in test, measurement, and automation solutions. As a key component of the PXI Express (PXle) platform, the PXLE-6544 is engineered to deliver exceptional performance in digital data acquisition and control applications.

Featuring 64 bidirectional digital I/O channels, the NI PXLE-6544 provides extensive connectivity for interfacing with a wide variety of digital devices. Its support for LVTTL and LVDS signal levels ensures compatibility with different types of digital circuits and systems. With a remarkable maximum data transfer rate of up to 800 MB/s, it can handle high – speed digital data streams with ease. Whether it’s for real – time monitoring of digital signals in industrial automation systems or precise control of digital actuators in research experiments, the PXLE-6544 offers the reliability and performance needed to meet the most demanding requirements. The optional channel – to – channel isolation feature adds an extra layer of protection, making it suitable for applications where electrical isolation between channels is crucial.

Core advantages and technical highlights

High – speed Data Handling: The NI PXLE-6544‘s ability to achieve a data transfer rate of up to 800 MB/s sets it apart in the market. In applications such as high – speed serial communication testing or rapid digital control of complex machinery, this high – speed data handling capability enables real – time interaction and immediate response. It reduces the latency between data acquisition or control commands and the actual system operation, ensuring smooth and efficient performance.

Versatile Signal Compatibility: By supporting both LVTTL and LVDS signal levels, the PXLE-6544 can interface with a broad range of digital components. LVTTL is commonly used in many standard digital circuits, while LVDS offers advantages such as low power consumption and high noise immunity for high – speed applications. This versatility allows the module to be integrated into diverse digital systems without the need for additional signal conversion components, simplifying system design and reducing costs.

Flexible Triggering Modes: The multiple triggering modes available on the NI PXLE-6544, including edge – triggered, level – triggered, and software – triggered, provide users with precise control over when data acquisition or control actions occur. In a quality control application where digital sensors detect the presence of a product on a conveyor belt, edge – triggering can be used to start data acquisition precisely when the product enters the detection zone. This flexibility enhances the accuracy and efficiency of digital measurement and control systems.

Reliable and Robust Design: Built to withstand the rigors of industrial and laboratory use, the PXLE-6544 has a durable construction. Its efficient power management, with a typical power consumption of 18 W, ensures stable operation while minimizing heat generation. The module’s ability to operate within a wide temperature range of 0 °C to 55 °C and withstand storage temperatures from – 40 °C to 70 °C makes it suitable for use in various environments, from controlled laboratory settings to harsh industrial plants.

NI PXLE-6544

Typical application scenarios

In industrial automation, the NI PXLE-6544 plays a vital role in factory – floor control systems. For example, in an automotive assembly line, it can be used to control the operation of robotic arms, conveyor belts, and other automated equipment. The high – speed data transfer and precise control capabilities of the PXLE-6544 enable seamless coordination between different components of the production line, ensuring efficient and error – free assembly processes. It can also monitor digital sensors that detect product quality, such as the presence of components or the correct positioning of parts, and trigger immediate corrective actions if any issues are detected.

In the electronics manufacturing industry, the PXLE-6544 is used for testing printed circuit boards (PCBs). It can generate and receive digital signals to test the functionality of various components on the PCB, such as microcontrollers, memory chips, and communication interfaces. The high – speed data transfer rate allows for rapid testing of multiple PCB samples, increasing the throughput of the testing process. The flexible triggering modes help in accurately capturing the responses of the tested components, enabling precise fault diagnosis.

In research and development laboratories, especially those focused on digital signal processing and control systems, the NI PXLE-6544 is an essential tool. Scientists and engineers can use it to develop and test new algorithms for digital control, such as those for autonomous vehicles or advanced robotics. Its high – speed I/O capabilities and versatile signal compatibility allow for the rapid prototyping and validation of digital systems, accelerating the research and development cycle.

Related model recommendations

- NI PXLE-6558: A related digital I/O module with more channels (128 bidirectional channels) compared to the PXLE-6544. It is suitable for applications that require a larger number of digital I/O connections, such as in large – scale industrial control systems or complex data acquisition setups where multiple digital devices need to be interfaced simultaneously.

- NI PXIe – 6570: This module offers high – speed digital pattern generation and acquisition capabilities. It can be used in conjunction with the PXLE-6544in applications that require both general – purpose digital I/O and complex digital pattern – based testing, such as in semiconductor device testing or communication protocol validation.

- NI PXLE-6363: A multifunctional I/O module that combines analog and digital I/O capabilities. When used with the PXLE-6544, it can provide a more comprehensive solution for systems that need to handle both analog and digital signals, such as in environmental monitoring systems where analog sensors measure physical parameters and digital sensors detect events.

- NI PXIe – 6537: A high – performance digital I/O module with enhanced timing and triggering features. It can be a complementary choice to the PXLE-6544in applications where extremely precise timing and synchronization of digital signals are required, such as in high – speed data communication research or advanced motion control systems.

- NI PXLE-6536: Similar to the PXLE-6544but with a different combination of features, such as lower power consumption in some operating modes. It can be considered as an alternative for applications where power efficiency is a critical factor while still maintaining reliable digital I/O performance.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXLE-6544, ensure that the PXI Express chassis is powered off and properly grounded. Check the compatibility of the chassis with the PXLE-6544 in terms of slot type and available power resources. Use appropriate electrostatic – discharge (ESD) protection measures, such as wearing an ESD wrist strap, to prevent damage to the module during handling. When inserting the PXLE-6544 into the chassis, align it carefully with the PXI Express slot and gently push it in until it clicks into place, ensuring a secure connection. Connect all necessary cables, such as power cables and signal cables, according to the wiring diagrams provided in the product manual.

Maintenance suggestions: Regularly inspect the status indicators on the PXLE-6544 to monitor its operation. Clean the ventilation openings of the module and the PXI Express chassis periodically to prevent dust accumulation, which can affect the heat dissipation and overall performance. Update the device drivers and firmware of the PXLE-6544 regularly to ensure compatibility with the latest software and to benefit from performance improvements and bug fixes. In case of any abnormal behavior, such as incorrect data readings or failure to respond to commands, first check the cable connections, power supply, and configuration settings. If the problem persists, refer to the troubleshooting guide in the product manual. When replacing any components, use only genuine NI parts to ensure the reliability and performance of the PXLE-6544.

Service and guarantee commitment

We stand firmly behind the quality of the NI PXLE-6544. The product comes with a comprehensive warranty that covers any manufacturing defects. During the warranty period, if the PXLE-6544 fails to perform as specified, we will repair or replace it free of charge. Our dedicated technical support team is available around – the – clock to assist customers with installation, commissioning, and any technical issues that may arise. We offer a wide range of online resources, including detailed user manuals, software drivers, and application notes, to help users make the most of the PXLE-6544. Additionally, we are committed to continuous product improvement and regularly release firmware updates and software enhancements to ensure that the PXLE-6544 remains at the forefront of digital I/O technology, providing our customers with reliable and high – performing solutions for their measurement and automation needs.