Description

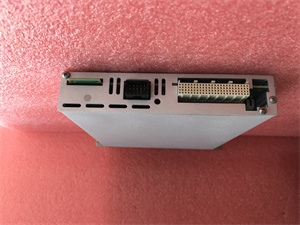

NI PXLE – 8133 Product Description

Product introduction

The NI PXLE – 8133 is a high – performance embedded controller from National Instruments (NI), designed to meet the demanding requirements of advanced test, measurement, and automation systems. As part of the PXI Express (PXle) platform, it offers exceptional processing power, high – speed data transfer capabilities, and reliable operation, making it an ideal choice for a wide range of applications.

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXLE – 8133 |

| Manufacturer | National Instruments (NI) |

| Product category | Embedded controller |

| Processor | [Specify the exact processor model, e.g., Intel Core i7 – [version] ] |

| Memory | [Specify the amount of RAM, e.g., 8GB DDR4 ] |

| Storage | [Describe the storage options, e.g., 256GB SSD ] |

| PXle interface | Supports high – speed PXle bus for data transfer |

| Communication interfaces | Ethernet for network connectivity, USB ports for peripheral connection |

| Operating system | Compatible with [List supported operating systems, e.g., Windows 10, NI Linux Real – Time ] |

| Dimensions | [Provide the physical dimensions in cm, e.g., 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H) ] |

| Power consumption | [Specify the power requirements, e.g., Up to [X] watts ] |

| Environmental requirements | Operating temperature: [Min – Max temperature range, e.g., 0 °C to 55 °C]; Storage temperature: [Min – Max temperature range, e.g., – 40 °C to 70 °C] |

NI PXLE-8133

Core advantages and technical highlights

Powerful Processing Performance: Equipped with a high – end processor, the NI PXLE – 8133 can handle complex computational tasks efficiently. For example, in data – intensive applications such as high – speed data acquisition and real – time signal processing, it can quickly analyze and process large volumes of data, ensuring accurate and timely results. The sufficient memory and fast storage options further enhance its processing capabilities, allowing for seamless operation even under heavy workloads.

High – speed Data Transfer: The PXle interface of the PXLE – 8133 enables extremely fast data transfer rates, which is crucial for applications that require rapid data exchange between different components of a measurement or automation system. This high – speed data transfer reduces the overall system latency and improves the real – time performance. For instance, when connected to high – speed data acquisition modules, it can quickly transfer the acquired data for further processing, enabling real – time monitoring and control.

Reliable and Stable Operation: Built with high – quality components and strict manufacturing standards, the NI PXLE – 8133 is designed to operate reliably in various environments. Its robust construction and efficient cooling mechanism ensure stable operation even under extended use and high – temperature conditions. In industrial settings where continuous operation is essential, the PXLE – 8133 can provide the reliability needed to keep the measurement and control systems running smoothly.

Versatile Compatibility: The PXLE – 8133 is compatible with a wide range of NI and third – party software and hardware. It supports popular operating systems, allowing users to choose the software environment that best suits their application requirements. Additionally, it can be easily integrated with other PXle modules, such as signal conditioning modules, data acquisition modules, and communication modules, to build customized and comprehensive measurement and automation systems.

Typical application scenarios

In industrial automation, the NI PXLE – 8133 is widely used for controlling and monitoring manufacturing processes. In a semiconductor manufacturing plant, it can be used to control the operation of complex production equipment, such as wafer processing machines. By connecting to various sensors and actuators through appropriate PXle modules, it can monitor process parameters in real – time, adjust the operation of the equipment, and ensure the quality and efficiency of the production process.

In the field of scientific research, especially in physics and engineering experiments, the PXLE – 8133 serves as a powerful data acquisition and analysis platform. For example, in a high – energy physics experiment, it can be used to acquire and analyze data from multiple detectors. Its high – speed data transfer and processing capabilities enable the real – time analysis of large amounts of experimental data, helping researchers to make timely discoveries and optimizations.

In the aerospace industry, the NI PXLE – 8133 is used for aircraft component testing and flight simulation. It can simulate various flight conditions and control the operation of test equipment to test the performance and reliability of aircraft components. The reliable operation and high – performance processing of the PXLE – 8133 are crucial for ensuring the safety and quality of aerospace products.

NI PXLE-8133

Related model recommendations

- NI PXLE – 8135: A more advanced version of the PXLE – 8133, offering higher processing power and additional features. It is suitable for applications that require even more intensive computational tasks, such as complex simulation and large – scale data analysis. When the requirements of the measurement and automation system grow, upgrading to the PXLE – 8135can provide enhanced performance.

- NI cRIO – 9068: A CompactRIO controller that provides a rugged and reliable solution for industrial and field – based applications. It has a different form factor and architecture compared to the PXLE – 8133, but can be used in combination with it in some scenarios. For example, in a distributed measurement system, the cRIO – 9068can be used for local data acquisition and pre – processing at the edge, while the PXLE – 8133 can be used for centralized data storage and in – depth analysis.

- NI PXI – 8840: A PXI controller that is also part of the NI controller family. It has its own unique features and advantages, such as different communication interface options and power consumption characteristics. In applications where cost – effectiveness and specific interface requirements are important, the PXI – 8840can be considered as an alternative to the PXLE – 8133. It can be used in less demanding applications or in systems where the PXI platform better suits the overall system design.

- NI PXle – 8880: This controller offers high – performance computing capabilities and advanced features for high – end applications. It can be used in parallel with the PXLE – 8133in a multi – controller system to handle different levels of processing tasks. For example, in a large – scale test and measurement system, the PXle – 8880 can handle the most computationally intensive tasks, while the PXLE – 8133 can manage the more routine data acquisition and control functions.

- NI IC – 3171: An industrial controller that is designed for harsh industrial environments. It has enhanced ruggedness and environmental resistance compared to the PXLE – 8133. In applications where the operating environment is extremely harsh, such as in mining or oil and gas industries, the IC – 3171can be used in combination with the PXLE – 8133 to ensure the reliable operation of the measurement and control system. The PXLE – 8133 can handle the more complex processing tasks, while the IC – 3171 can be responsible for the connection and control of equipment in the harsh environment.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXLE – 8133, ensure that the PXI Express chassis is properly grounded and powered off. Check the compatibility of the chassis with the PXLE – 8133 in terms of slot type and power supply capacity. Gather the necessary tools, such as a screwdriver. When inserting the PXLE – 8133 into the chassis, carefully align it with the slot and gently push it in until it is firmly seated. Make sure all the connections, including power cables, PXle cables, and communication cables, are properly connected and secured.

Maintenance suggestions: Regularly check the status indicators on the PXLE – 8133 and the PXI Express chassis to monitor its operation. Clean the ventilation openings of the PXLE – 8133 and the chassis regularly to prevent dust accumulation, which can affect the cooling efficiency and lead to overheating. Periodically update the operating system and software drivers to ensure compatibility and performance optimization. In case of any abnormal behavior, such as system crashes or data transfer errors, first check the hardware connections and configuration settings. If the problem persists, refer to the troubleshooting guide in the product manual. When replacing any components, use only genuine NI parts to ensure compatibility and maintain the high – quality performance of the PXLE – 8133.

Service and guarantee commitment

We are fully committed to the quality and reliability of the NI PXLE – 8133. The product comes with a comprehensive warranty that covers any manufacturing defects. During the warranty period, if the PXLE – 8133 fails to perform as specified, we will repair or replace it free of charge. Our dedicated technical support team is available around the clock to assist customers with installation, commissioning, and any technical issues. We offer a wide range of online resources, including detailed user manuals, software drivers, and application notes, to help users make the most of the PXLE – 8133. Additionally, we are constantly working on product improvement and will release firmware updates and software enhancements to keep the PXLE – 8133 at the forefront of technology, ensuring that our customers’ measurement and automation systems remain competitive.