Description

1. Product Introduction

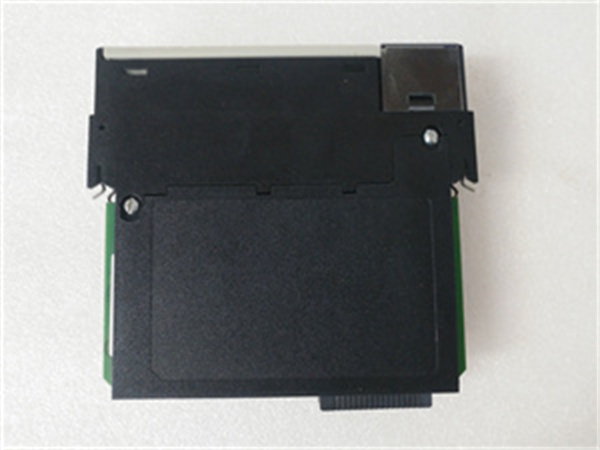

The PROSOFT MVI46 – ADMNET is a sophisticated communication module developed by ProSoft Technology, specifically engineered for Allen – Bradley SLC 500 processors. In the landscape of industrial automation, where seamless communication between diverse devices is crucial, this module plays a pivotal role. It bridges the gap between SLC 500 processors and Ethernet – enabled devices, enabling efficient data exchange and control.

Unlike some basic communication modules, the MVI46 – ADMNET is not just a simple connectivity solution. It is designed to handle complex communication tasks, allowing for the implementation of custom – tailored communication protocols. This makes it an ideal choice for industries such as manufacturing, oil and gas, electrical power, and food processing, where unique communication requirements often arise.

2. Functional Features

2.1 Ethernet Connectivity

The module features a 10/100 – base – T Ethernet interface, which enables high – speed communication with other devices on the network. This includes computers, servers, and other PLCs. The Ethernet connectivity allows for easy integration into existing industrial networks, whether they are small – scale local networks or large – scale enterprise – wide systems. For example, in a manufacturing plant, the MVI46 – ADMNET can connect SLC 500 processors to a central control system, facilitating real – time monitoring and control of production processes.

2.2 C Programming Capability

One of the most notable features of the MVI46 – ADMNET is its support for C programming. This provides users with a high degree of flexibility and customization. With C programming, developers can create custom communication protocols and applications that are tailored to the specific needs of their industrial processes. For instance, in a power generation facility, engineers can use C programming to develop a protocol that enables the SLC 500 processor to communicate with specialized power monitoring devices, collecting and analyzing data in a way that standard off – the – shelf protocols cannot.

2.3 In – Chassis Installation

The MVI46 – ADMNET is designed for in – chassis installation, directly mounting into the SLC 500 processor. This not only saves valuable space in the control cabinet but also reduces wiring complexity. By eliminating the need for external mounting and extensive cabling, the module enhances the overall reliability and maintainability of the system. In a crowded control room, the in – chassis installation of the MVI46 – ADMNET helps to keep the setup organized and minimizes the risk of cable damage or disconnection.

2.4 Wide Compatibility

This module is compatible with various SLC 500 models, ensuring broad applicability across different industrial setups. It also supports different communication protocols, making it versatile in handling diverse communication tasks. Whether it’s communicating with legacy devices using ASCII protocols or connecting to modern Ethernet – based sensors and actuators, the MVI46 – ADMNET can adapt to the requirements. In an oil refinery, for example, it can interface with both older monitoring equipment using legacy protocols and new – generation flow meters and valves that communicate via Ethernet.

2.5 Serial Ports Configuration

The MVI46 – ADMNET comes with three serial ports, two of which are isolated for field interfaces. The ports, PRT1 and PRT2, can be jumper – configured for direct or multidrop field communication. This allows for seamless connection to a wide range of field devices, such as bar code scanners, printers, and legacy terminal equipment. In a logistics warehouse, the module’s serial ports can be used to interface with bar code scanners, enabling the SLC 500 system to track inventory movements accurately.

PROSOFT SST-PB3-CLX

3. Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | PROSOFT MVI46 – ADMNET |

| Manufacturer | ProSoft Technology |

| Product Category | Communication Module (for Allen – Bradley SLC 500) |

| Compatible PLCs | Allen – Bradley SLC 500 series |

| Supported Protocols | Ethernet/IP, Custom C – based protocols, Legacy ASCII (through serial ports) |

| Ethernet Port | 1x 10/100 – base – T RJ45; Auto – MDI/MDI – X; Link/activity LEDs |

| Serial Ports | 3 serial ports (2 isolated); RS – 232 configuration port, 2 serial application ports (PRT1 and PRT2) |

| Power Requirements | 5 VDC from SLC 500 backplane; Current consumption: < 800 mA (operating mode) |

| Physical Dimensions | 263 mm (L) × 58 mm (W) × 28 mm (D); Weight: ~[weight value not provided in source] |

| Environmental Ratings | Operating temperature: 0 °C to +60 °C; Storage temperature: – 40 °C to +85 °C; Relative humidity: 5% – 95% (non – condensing); Vibration: 5 g (10 – 150 Hz, IEC 60068 – 2 – 6); Shock: 30 g (11 ms half – sine, IEC 60068 – 2 – 27) |

| Safety & Compliance | CE (EN 61010 – 1, EN 61326 – 1); UL 61010 – 1 (USA/Canada); RoHS 2 compliant (2011/65/EU) |

| Configuration | User – defined ladder logic (sample ladder file included); C programming using provided APIs |

PROSOFT SST-PB3-CLX

4. Application Scenarios

4.1 Manufacturing

In a manufacturing plant, the MVI46 – ADMNET can be used to connect SLC 500 – based control systems to various production line devices. For example, it can interface with bar code scanners to track the movement of products along the assembly line. The module’s Ethernet connectivity allows for real – time data transfer to a central production management system, enabling managers to monitor production rates, identify bottlenecks, and make informed decisions. Additionally, the C programming capability can be utilized to develop custom communication protocols for specialized manufacturing equipment, such as robotic arms or high – precision measurement devices.

4.2 Oil and Gas

In the oil and gas industry, the MVI46 – ADMNET plays a crucial role in monitoring and controlling operations. It can connect SLC 500 processors to remote field devices, such as flow meters, pressure sensors, and valves. The module’s serial ports can be used to communicate with legacy monitoring equipment, while the Ethernet port enables high – speed data transfer to a central control room. For instance, in an oil pipeline monitoring system, the MVI46 – ADMNET can collect data from multiple sensors along the pipeline and transmit it to a control center for analysis. In case of any abnormal readings, the SLC 500 processor can send commands to the valves to shut off the flow, preventing potential leaks.

4.3 Electrical Power

In power generation and distribution systems, the MVI46 – ADMNET is used to integrate SLC 500 – based control systems with power monitoring and control devices. It can communicate with smart meters, circuit breakers, and other power – related equipment. The C programming feature allows for the development of custom algorithms to analyze power quality data, such as voltage sags, swells, and harmonics. In a power substation, the module can connect the SLC 500 processor to multiple smart meters, collecting data on power consumption and generation. This data can then be used to optimize power distribution and ensure grid stability.

4.4 Food Processing

In the food processing industry, where hygiene and precision are critical, the MVI46 – ADMNET helps in automating production processes. It can connect SLC 500 processors to food handling equipment, such as conveyors, mixers, and packaging machines. The module’s in – chassis installation is beneficial in a food processing environment, as it reduces the risk of contamination from external wiring. The Ethernet connectivity enables seamless integration with quality control systems, allowing for real – time monitoring of product quality. For example, the module can be used to connect a SLC 500 – controlled packaging machine to a vision – based quality inspection system, ensuring that only products of the highest quality are packaged and shipped.

5. Installation, Commissioning, and Maintenance

5.1 Installation

Chassis Preparation: Ensure that the SLC 500 chassis has an available slot. Power off the SLC 500 system to prevent any electrical damage during installation. Use an ESD (electro – static discharge) wristband to protect the module from static electricity.

Module Mounting: Align the MVI46 – ADMNET with the chassis slot and firmly insert it. Make sure the module is properly seated to ensure a secure connection to the backplane.

Wiring: Connect the Ethernet cable to the module’s RJ45 port. For serial connections, connect the appropriate serial cables to the PRT1, PRT2, and configuration ports as required. The module draws power from the SLC 500 backplane, so no external power supply is needed.

Power – On: After all connections are made, power on the SLC 500 system. Verify that the module’s LEDs (such as power, Ethernet link, and serial activity LEDs) are functioning correctly.

5.2 Commissioning

Software Setup: Install the necessary programming software, such as Rockwell Software’s RSLinx. Import the appropriate drivers or configuration files for the MVI46 – ADMNET. Connect a PC to the SLC 500 Ethernet port or serial port (depending on the configuration method).

Configuration:

Ethernet Settings: Configure the Ethernet IP address, subnet mask, and gateway for the module. This will enable communication with other devices on the network.

Serial Port Configuration: Set the baud rate, parity, data bits, and stop bits for the serial ports according to the requirements of the connected devices.

C Programming (if applicable): If developing custom applications using C, write and compile the code using the provided APIs. Load the custom code into the module.

Ladder Logic Configuration: Use ladder logic to configure data transfer between the module and the SLC 500 processor. Refer to the sample ladder file provided for guidance.

Testing: Use diagnostic tools or custom – written test programs to verify communication. For Ethernet communication, ping the module’s IP address from a connected device. For serial communication, send and receive test data between the module and the connected serial devices.

5.3 Maintenance

Regular Checks: Periodically inspect the module’s LEDs to ensure normal operation. Check for any signs of physical damage, such as loose connections or overheating. Clean the Ethernet and serial ports if necessary to remove dust or debris.

Troubleshooting: If communication issues occur, first check the network and serial connections. Verify that the IP settings, baud rates, and other configuration parameters are correct. Use diagnostic software or the module’s built – in diagnostic functions to identify and resolve problems. If the problem persists, contact ProSoft Technology’s technical support.

Firmware Updates: Periodically check ProSoft Technology’s website for firmware updates. Download and install the latest firmware to ensure optimal performance and compatibility. Follow the provided instructions carefully during the firmware update process.

Spare Parts Management: Keep spare MVI46 – ADMNET modules on hand to minimize downtime in case of module failure. Store spare modules in a suitable environment, following the recommended temperature and humidity guidelines.

6. Service and Warranty

ProSoft Technology offers a standard [warranty duration not provided in source] warranty for the MVI46 – ADMNET. This warranty covers defects in materials and workmanship. For customers with critical applications, ProSoft also provides additional support services, such as:

Technical support: ProSoft’s team of experts is available to assist with installation, configuration, and troubleshooting. They can be reached via phone, email, or online support portals.

Training: ProSoft offers training courses on using the MVI46 – ADMNET, including programming in C and configuration using ladder logic. These courses can be customized to meet the specific needs of customers.

Product updates: Customers receive notifications of product updates, including firmware upgrades and new features. This ensures that their MVI46 – ADMNET modules remain up – to – date and compatible with the latest technologies.

For out – of – warranty repairs, ProSoft provides a reliable repair service. Their repair facilities are equipped to diagnose and fix issues with the MVI46 – ADMNET. Repaired modules are typically covered by a [repair warranty duration not provided in source] warranty, giving customers peace of mind.