Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | 0 – 60031 – 5 |

| Manufacturer | Reliance Electric |

| Product category | Resolver and Drive I/O PMI |

| Function | Serves as a crucial interface for resolver – based feedback and drive input/output operations within an industrial automation system. It enables the transfer of data related to motor position (from the resolver) and controls the input and output signals for the drive system, facilitating seamless communication between different components such as motors, sensors, and control units |

| Electrical characteristics | While specific voltage and current ratings are not publicly disclosed in standard product overviews, it is designed to operate within the electrical parameters compatible with the overall drive system it is integrated into. For example, if used in a DC drive system like the 8036011SRR (which includes the 0 – 60031 – 5 as a component), it would be engineered to work with the power supply voltages and current levels associated with that system, such as those provided by the 0 – 60007 – 2 power supply within the 8036011SRR module |

| Interface details | Equipped with connectors for seamless connection to resolver devices, allowing for the accurate transfer of position feedback signals. It also features input and output terminals for connecting to other drive – related components, such as sensors and actuators. These interfaces are designed to ensure reliable data transfer and electrical connectivity within the industrial control environment |

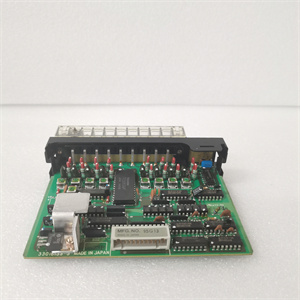

| Physical dimensions (approx.) | Given its role as a circuit board – like component within a larger power module, it likely has dimensions that are compact enough to fit within standard industrial control cabinets. While exact dimensions are not widely available, it may have a form factor similar to other drive – related circuit boards, perhaps with a length of around 150 – 200 mm, a width of 80 – 120 mm, and a thickness of 10 – 20 mm, to be easily integrated into the overall system layout |

| Weight (approx.) | Being a relatively small – scale electronic component, it is lightweight, weighing approximately 0.2 – 0.5 kg. This makes it easy to handle during installation, maintenance, and replacement procedures |

Reliance 0-60031-5

Product Introduction

The Reliance 0 – 60031 – 5 is a specialized Resolver and Drive I/O PMI (Position Measurement Interface) module, designed to play a pivotal role in industrial automation systems. As a product of Reliance Electric, a well – known name in the field of electrical and automation solutions, the 0 – 60031 – 5 is engineered to ensure accurate position feedback and efficient drive control.

This module acts as a bridge between resolver – based position sensors and the drive system. Resolvers are essential in industrial applications for providing precise angular position information of motors or other rotating components. The 0 – 60031 – 5 receives these resolver signals, processes them, and then feeds the relevant data to the drive system for accurate control. It also manages the input and output signals related to the drive, enabling seamless communication between different parts of the automation setup. Whether used in manufacturing plants, industrial machinery, or other industrial processes that require precise motion control, the 0 – 60031 – 5 contributes to the overall efficiency and accuracy of the system.

Core Advantages and Technical Highlights

Precise Resolver Signal Processing

The 0 – 60031 – 5 is optimized for high – precision resolver signal processing. Resolvers generate analog signals that represent the angular position of a rotating shaft. The module is equipped with advanced signal – conditioning circuitry and processing algorithms to convert these analog signals into digital data that can be easily understood by the drive system. This high – accuracy processing ensures that the drive system can precisely control the position and speed of motors. In a CNC machine, for example, accurate resolver signal processing by the 0 – 60031 – 5 enables the machine to position the cutting tool with micron – level precision, resulting in high – quality machining of parts.

Reliable Drive I/O Interface

As a drive I/O module, the 0 – 60031 – 5 offers a reliable interface for connecting various components in the drive system. It has robust input and output terminals that can withstand the electrical and mechanical stresses of industrial environments. The module is designed to handle different types of signals, including digital and analog, from sensors such as limit switches, proximity sensors, and temperature sensors. It also provides outputs to control actuators like relays and solenoids. In a conveyor belt system, the 0 – 60031 – 5 can receive signals from sensors that detect the presence of objects on the belt and then send control signals to actuators that start or stop the conveyor motor, ensuring smooth and efficient material handling.

Compact and Space – Saving Design

With its compact physical dimensions, the 0 – 60031 – 5 is highly suitable for applications where space is at a premium. In modern industrial control cabinets, where multiple components need to be integrated, the small form factor of this module allows for efficient use of space. It can be easily installed in tight spaces, reducing the overall footprint of the control system. This space – saving design is particularly beneficial in applications such as small – scale manufacturing equipment or mobile industrial machinery, where every inch of space matters.

Compatibility with Reliance Drive Systems

The 0 – 60031 – 5 is specifically designed to be compatible with Reliance’s range of drive systems. This compatibility ensures seamless integration and optimal performance. When used within a Reliance – based drive system, such as the 8036011SRR DC power module (which includes the 0 – 60031 – 5 as a component), the module can communicate effectively with other parts of the system, such as the power supply, processor, and other boards. This compatibility simplifies system design, installation, and maintenance, as all components are engineered to work together harmoniously.

Typical Application Scenarios

Industrial Machinery

In industrial machinery such as lathes, milling machines, and grinders, the Reliance 0 – 60031 – 5 is used to control the movement of the machine’s axes. Resolvers attached to the motors driving these axes provide position feedback to the 0 – 60031 – 5. The module then processes this information and sends control signals to the drive system, ensuring that the cutting tools or workpieces are moved precisely. In a lathe, for instance, the 0 – 60031 – 5 enables the accurate positioning of the tool post, allowing for the machining of complex shapes and tight tolerances.

Automated Assembly Lines

Automated assembly lines rely on precise motion control to ensure the efficient and accurate assembly of products. The 0 – 60031 – 5 is used to interface with the motors and sensors in robotic arms and conveyor systems. In a robotic arm, resolvers on the joints provide position information to the 0 – 60031 – 5, which then controls the drive system to move the arm precisely for tasks such as picking and placing components. In a conveyor system, the module can receive signals from sensors that detect the position of products and control the speed and direction of the conveyor motors to ensure smooth product flow.

Material Handling Systems

In material handling systems, such as those used in warehouses or distribution centers, the 0 – 60031 – 5 is used to control the movement of automated guided vehicles (AGVs) and cranes. Resolvers on the motors of these vehicles and cranes provide position feedback to the module, which then controls the drive system to ensure accurate positioning. For example, in an AGV used to transport pallets in a warehouse, the 0 – 60031 – 5 enables the vehicle to navigate through the aisles and precisely position itself at loading and unloading stations.

Related Model Recommendations

Reliance 0 – 60007 – 2 Power Supply: When used in a system like the 8036011SRR DC power module, the 0 – 60007 – 2 power supply provides the necessary electrical power for the 0 – 60031 – 5 and other components in the system. It is designed to work in harmony with the 0 – 60031 – 5, ensuring stable and reliable operation of the overall drive system.

Reliance 0 – 60021 – 4 PMI Processor: This processor can work in tandem with the 0 – 60031 – 5 to enhance the processing capabilities of the resolver signals and drive control operations. In a complex industrial control system, the combination of the 0 – 60021 – 4 processor and the 0 – 60031 – 5 can improve the overall performance and accuracy of the motion control.

Reliance 0 – 60031 – 6 Resolver and Drive I/O Module: Similar to the 0 – 60031 – 5, the 0 – 60031 – 6 can be used in cases where additional resolver and drive I/O functionality is required. It may have some differences in features or capabilities, but it can be integrated into the same type of industrial control systems, providing users with options for system expansion or customization.

Reliance 0-60031-5

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Reliance 0 – 60031 – 5, ensure that the installation area is clean, dry, and free from excessive dust and electromagnetic interference. Tools required for installation include a screwdriver for securing the module in place and a cable tester to check the integrity of the communication cables. Disconnect all power sources from the system to avoid electrical shocks during installation. When connecting the resolver cables to the module, make sure to follow the wiring diagram provided in the product manual carefully to ensure proper connection. Verify that the drive system into which the 0 – 60031 – 5 is being installed is compatible with the module’s electrical and communication specifications.

Maintenance Suggestions

For routine maintenance of the 0 – 60031 – 5, perform visual inspections regularly. Check for any signs of physical damage to the module, such as cracks on the circuit board or loose connectors. Use compressed air to clean dust from the module, especially around the ventilation areas. Periodically test the resolver signal processing and drive I/O functionality using diagnostic tools. If any communication errors occur, check the cable connections, verify the electrical integrity of the module, and ensure that the module’s firmware (if applicable) is up – to – date. When replacing the module, ensure that the new module is of the same model and is properly configured according to the system requirements.

Service and Guarantee Commitment

Reliance’s warranty policy for the 0 – 60031 – 5 typically covers manufacturing defects for a specified period, although the exact duration may vary depending on the region and specific terms of purchase. In general, for direct customers, if the module is found to be defective due to manufacturing issues within the warranty period, Reliance will repair or replace it. However, it’s important to note that the warranty may be non – transferable. Additionally, Reliance may offer technical support services to assist customers with installation, configuration, and troubleshooting. Customers can often access user manuals, installation guides, and other technical resources through Reliance’s official channels, which may include their website or customer support portals. This commitment to product quality and customer support reflects Reliance’s dedication to providing reliable industrial automation solutions.