Description

Product Overview

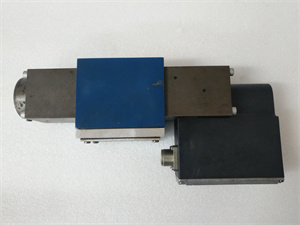

The REXROTH 0608820115 is a high – performance tightening system, which is a key product in REXROTH’s industrial automation product line. This tightening system is designed to provide precise tightening force control, mainly used in assembly lines and other scenarios where precise tightening is required. As a part of REXROTH’s automation system, it has a high – end positioning, aiming to help manufacturers improve the quality and efficiency of assembly. The system can accurately output a tightening torque of 160 Nm, ensuring that each tightened part meets the specified requirements, reducing the occurrence of assembly defects. With REXROTH’s advanced technology and high – quality manufacturing process, the 0608820115 tightening system has the characteristics of high reliability and stability, and can work stably in a variety of industrial environments, providing strong support for the automation and intelligence of the production process.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 0608820115 |

| Manufacturer | REXROTH |

| Product Type | Tightening System |

| Rated Torque | 160 Nm |

| Input Voltage | According to the specific model and configuration, generally common industrial voltage |

| Communication Protocol | Support common industrial communication protocols, such as Profibus, etc. (specific to be determined according to the actual situation) |

| Working Temperature Range | – 10℃ – 50℃ |

| Working Humidity Range | 10% – 90% non – condensing |

| Physical Dimensions | Compact design, suitable for installation in limited spaces (specific dimensions need to refer to the product manual) |

| Installation Method | Can be installed on the assembly line according to the actual needs, support fixed installation |

| Accuracy | High – precision torque control, accuracy can reach ± 5% |

| Load Capacity | Can meet the tightening requirements of general industrial parts |

| Life Expectancy | Under normal use conditions, the service life can reach more than 10 years |

REXROTH 0608820115

Main Features and Advantages

The REXROTH 0608820115 tightening system has the advantage of high – precision torque control. It can accurately output the set torque of 160 Nm, and the accuracy can reach ± 5%, which ensures the consistency of the tightening force of each part and is very suitable for high – precision assembly operations.

Reliable and stable: Relying on REXROTH’s excellent manufacturing technology and high – quality materials, this system can work stably in a harsh industrial environment with a working temperature range of – 10℃ – 50℃. The components have a long service life, and the normal service life can reach more than 10 years, reducing the frequency of equipment maintenance and replacement.

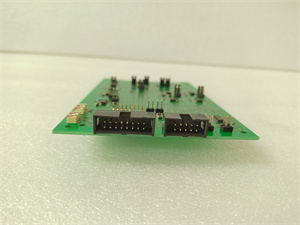

Flexible communication: It supports common industrial communication protocols, which can be easily integrated into the factory’s overall automation control system, realizing data interaction and remote control with other equipment, and facilitating the realization of intelligent production.

Compact design: Its physical dimensions are designed to be compact, which can be flexibly installed in various assembly line workstations, especially suitable for occasions with limited space, without taking up too much production space.

Application Field

The REXROTH 0608820115 tightening system is widely used in the automotive manufacturing industry. In the automotive assembly process, such as engine assembly, wheel installation, and body part connection, precise tightening is required. This tightening system can ensure that each bolt and nut is tightened to the specified torque, improving the quality and safety of the vehicle.

It is also applicable to the electronic product manufacturing industry. In the production of electronic products, the assembly of small – sized components also requires precise force control. The high – precision characteristics of the 0608820115 can meet the assembly requirements of these components, reducing the defective rate of products.

In addition, in the machinery manufacturing industry, for the assembly of various mechanical equipment, whether it is large – scale heavy – duty machinery or small – scale precision machinery, this tightening system can play an important role, helping manufacturers improve production efficiency and product quality, and is an indispensable part of the modern industrial assembly line.

REXROTH 0608820115

Related Products

- REXROTH 0608820116: It is an upgraded version of 0608820115, with higher torque accuracy and more stable performance, suitable for more high – end precision assembly scenarios.

- REXROTH 0608820114: A basic model, with a lower torque range, mainly used for some simple assembly operations with lower precision requirements.

- REXROTH 0608820117: Equipped with a more advanced communication module, which can better adapt to the new – generation industrial Ethernet communication protocol, and is suitable for the intelligent factory with higher communication requirements.

- REXROTH 0608820113: Has a smaller volume, suitable for use in some occasions with extremely limited space, and its basic performance is similar to that of 0608820115.

- REXROTH 0608820118: With a self – diagnosis function, it can automatically detect the fault of the system and give an alarm, which is convenient for maintenance and reduces the downtime of the production line.

Installation and Maintenance

Pre – installation preparation: Before installing the REXROTH 0608820115 tightening system, it is necessary to check whether the installation site meets the requirements, ensure that the temperature and humidity of the working environment are within the specified range of the product, and clean the installation position to prevent dust and debris from affecting the installation and operation of the equipment. At the same time, according to the actual needs of the assembly line, select the appropriate installation method, and prepare the corresponding installation tools and fixing parts. Check whether the power supply and communication lines are in good condition to ensure that the voltage and communication protocol meet the requirements of the equipment.

Maintenance recommendations: Regularly clean the surface of the 0608820115 tightening system to keep it clean and free of dust and oil stains. Check the connection of each component regularly to ensure that there is no loose phenomenon. Periodically calibrate the torque of the system to ensure its torque output accuracy. If an abnormal noise or vibration is found during operation, stop the machine immediately for inspection, and replace the damaged components in time according to the inspection results. According to the actual use frequency, regularly replace the wearing parts to ensure the normal operation of the system.

Product Guarantee

REXROTH provides a reliable product guarantee for the 0608820115 tightening system. The product has passed strict quality inspection before leaving the factory to ensure that it meets high – quality standards. REXROTH offers a certain – period quality warranty, during which, if there are quality problems caused by non – human factors, free repair or replacement services will be provided. At the same time, REXROTH provides comprehensive after – sales service and technical support, and professional technicians are on – call to solve various problems encountered by customers during use, ensuring that the 0608820115 tightening system can play a stable performance in the production process and create value for customers.