Description

Product Overview

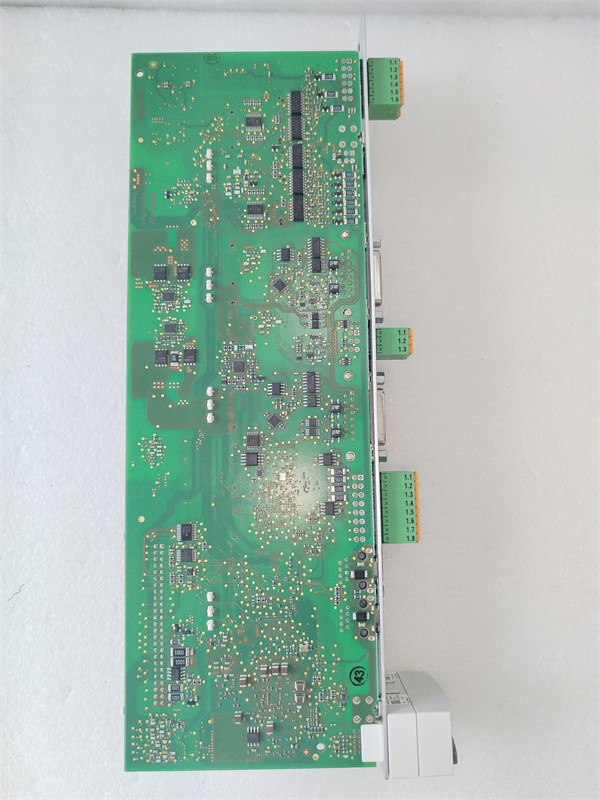

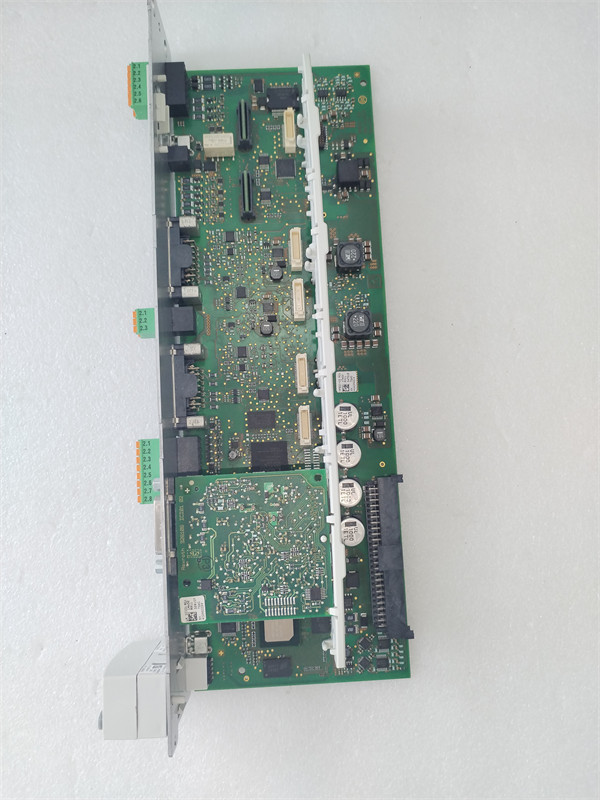

The REXROTH CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW is a high – end drive controller, representing a remarkable offering within REXROTH’s IndraDrive product series. This controller is meticulously engineered to meet the demands of complex industrial automation scenarios, playing a pivotal role in ensuring seamless and efficient operation of machinery and production lines.

It serves as a central hub for controlling various aspects of drive systems. With advanced control algorithms integrated, the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW can precisely regulate motor speed, torque, and position. This high – level control ability enables it to optimize the performance of connected motors, whether in high – speed manufacturing processes or in applications that require delicate and accurate movements. Additionally, it is designed to be highly adaptable, capable of integrating with a wide range of industrial networks and other automation components, making it a versatile choice for diverse industrial setups.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW |

| Manufacturer | REXROTH |

| Product Type | Drive Controller |

| Master Communication | Multi – Ethernet |

| Option 1 | Factory – assigned |

| Option 2 | Factory – assigned |

| Safety Option | Factory – assigned |

| Input Voltage | Suitable for common industrial voltage levels (specific values vary based on configuration) |

| Output Current Capacity | Can drive motors with specific current requirements (varies according to the motor it is paired with) |

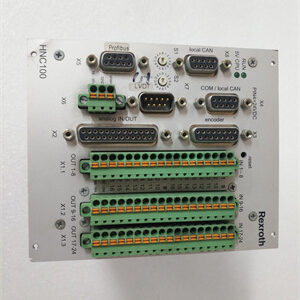

| Communication Protocols | Supports industrial – standard protocols like Profibus, Ethernet/IP (in addition to Multi – Ethernet) |

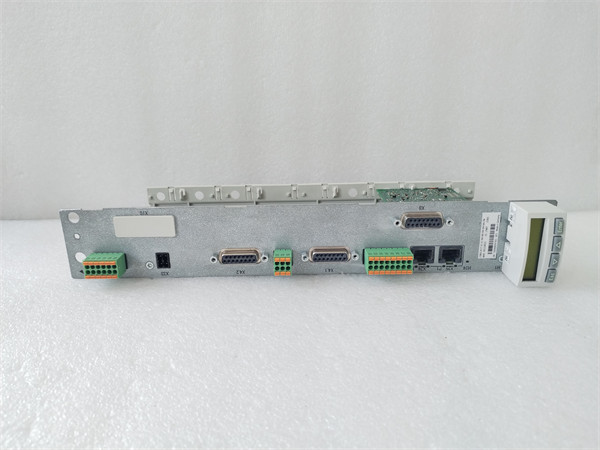

| Physical Dimensions | Compact design for easy installation in control cabinets, with specific dimensions available in the product manual |

| Working Temperature Range | Generally – 10°C to 50°C, ensuring stable operation in typical industrial environments |

| Working Humidity Range | 10% – 90% non – condensing |

| Control Accuracy | High – precision control, for example, speed control accuracy can reach within a very small percentage |

| Encoder Compatibility | Compatible with various encoder types such as IndraDyn, Hiperface, 1 Vpp, TTL, Endat, SSI, and resolver |

REXROTH CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW

Main Features and Advantages

High – Performance Control

The REXROTH CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW offers outstanding control capabilities. Its advanced algorithms allow for precise regulation of motor parameters. For instance, it can control motor speed with high accuracy, which is crucial in applications where consistent speed is required, such as in textile manufacturing or printing presses. The ability to accurately adjust torque ensures that the connected machinery can handle different loads efficiently, reducing the risk of motor burnout and improving overall equipment lifespan.

Versatile Communication

This drive controller supports multiple communication protocols, especially the Multi – Ethernet master communication. This feature enables seamless integration with different industrial networks. It can easily communicate with Programmable Logic Controllers (PLCs), Human – Machine Interfaces (HMIs), and other devices in the automation ecosystem. This versatility in communication promotes real – time data exchange, allowing for better monitoring and control of the entire production process. It also makes it easier to retrofit into existing industrial setups without major rewiring or network overhauls.

Reliable and Robust Design

Built with REXROTH’s renowned engineering expertise, the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW is designed to be highly reliable. It can withstand harsh industrial environments, with a wide working temperature and humidity range. The components used are of high quality, ensuring long – term stable operation. The controller also has built – in diagnostic and protection functions. In case of abnormal conditions such as over – current or over – temperature, it can quickly detect the problem and take appropriate measures to protect the connected equipment, minimizing production downtime.

REXROTH CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW

Application Field

The REXROTH CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW finds extensive applications across various industries. In the automotive manufacturing industry, it is used to control the motors in assembly line robots. These robots require precise control of movement, and the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW ensures that each part is accurately placed, contributing to high – quality vehicle production.

In the packaging industry, this drive controller is employed to control conveyor belts and packaging machinery. Precise speed and position control are essential to ensure that products are packaged correctly and efficiently. The ability of the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW to communicate with other devices in the packaging line allows for seamless coordination of different processes, from product filling to sealing.

It is also widely used in the machine tool industry. Machine tools need to perform complex and accurate machining operations. The CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW controls the spindle and axis motors, enabling high – precision cutting, drilling, and milling, which is crucial for producing high – quality machined parts.

Related Products

- 1C – PB – EN2 – EN2 – NNN – NNN – S2 – S – NN – FW: A different model in the CDB series. It has a different power rating compared to the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW, making it suitable for applications with lower power requirements. It also has a different set of communication and encoder compatibility options, which may be more suitable for certain less complex industrial setups.

- 1B – ET – EC – EC – S4 – NN – NN – FW: Another compact converter in the IndraDrive product line. It has a similar form factor but different control capabilities. For example, its control algorithms may be optimized for different types of motors or application scenarios, such as applications that require more focch as applications that require more focus on speed control rather than torque control like the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FWin some cases.

- 1E – W0006 – A – 02 – B – ET – EC – NN – NN – NN – FW: A servo controller from REXROTH. While the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FWis a drive controller, the HCS01.1E series focuses more on servo – specific functions. It may have different levels of precision in position control and may be used in applications where high – precision positioning of servo – motors is the primary requirement, as opposed to the more general – purpose drive control of the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW.

- 1N – W0036 – A – 07 – NNNN: This is a motor – related product. It can be paired with the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FWin some industrial applications. The motor is designed to work in tandem with the drive controller, with the controller regulating the motor’s operation according to the requirements of the production process.

- 1C – CO – ENS – NNN – NN – S – NN – FW: A drive controller with a different configuration. It has a simpler communication setup compared to the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW, which may be suitable for smaller – scale industrial applications or for those where the communication requirements are not as complex.

Installation and Maintenance

Pre – installation preparation: Before installing the REXROTH CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW, ensure that the control cabinet is properly grounded. Check the physical dimensions of the cabinet to ensure a proper fit for the compact – sized controller. Verify that the input voltage of the installation site matches the requirements of the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW. Also, make sure to have the appropriate software for configuration installed on the connected device. Prepare all the necessary communication cables and ensure they are of the correct type and in good condition.

Maintenance recommendations: Regularly check the status indicators on the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW to monitor its operational health. Periodically update the controller’s firmware to benefit from the latest features, bug fixes, and security enhancements. Clean the controller from dust and debris regularly, especially in industrial environments with high particulate matter, as this can affect its performance over time. Conduct routine diagnostic tests using the controller’s built – in diagnostic tools to detect any potential issues early on. If any abnormal behavior is observed, such as erratic motor control or communication failures, follow the troubleshooting guide provided in the product manual or contact REXROTH’s technical support for assistance.

Product Guarantee

REXROTH stands firmly behind the quality of the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW drive controller. The product undergoes rigorous quality inspection before leaving the factory to ensure it meets the highest industry standards. REXROTH offers a comprehensive product guarantee, typically including a one – year warranty. During this period, if there are any quality issues caused by manufacturing defects, REXROTH will provide free repair or replacement services. In addition, REXROTH’s professional technical support team is always available to assist customers. Whether it’s helping with installation, configuration, or troubleshooting, they are committed to ensuring that customers can use the CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW with confidence in their industrial automation applications, minimizing production disruptions and maximizing the value of the product.