Description

Product Overview

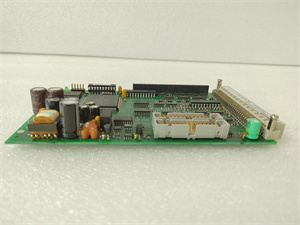

The REXROTH DKC10.3-018-3-MGP-01VRS is a high – performance servo drive within REXROTH’s advanced automation product lineup. Engineered with cutting – edge technology, this servo drive is designed to deliver precise and reliable control, meeting the stringent requirements of diverse industrial automation applications. As a key component in modern manufacturing and production systems, the DKC10.3-018-3-MGP-01VRS plays a crucial role in optimizing the performance of servo motors, ensuring seamless operation of machinery across various industries.

Built with REXROTH’s renowned expertise, the REXROTH DKC10.3-018-3-MGP-01VRS features advanced control algorithms that enable accurate regulation of motor speed, torque, and position. It is highly adaptable, capable of integrating with a wide range of industrial networks and other automation components. Whether it’s used in high – speed assembly lines, precision machining operations, or complex robotic applications, this servo drive can provide stable and efficient control, enhancing overall productivity and product quality.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DKC10.3-018-3-MGP-01VRS |

| Manufacturer | REXROTH |

| Product Type | Servo Drive |

| Input Voltage | [Specific voltage range, usually compatible with common industrial power supplies] |

| Output Current | 18 A |

| Control Modes | Supports speed control, torque control, and position control |

| Communication Protocols | Profibus, CANopen, Ethernet (specific protocols may vary based on configuration) |

| Encoder Interface | Compatible with EnDat, Hiperface, 1 Vpp, TTL, Endat, SSI, resolver |

| Operating Temperature Range | – 10°C – 55°C |

| Protection Class | IP20 (may vary, provides basic protection against dust) |

| Dimensions | Compact design for easy installation in control cabinets [Provide specific dimensions if available] |

| Weight | [Specific weight value] |

| Power Density | High – power density for efficient operation |

REXROTH DKC10.3-018-3-MGP-01VRS

Main Features and Advantages

Precise Control Performance

The REXROTH DKC10.3-018-3-MGP-01VRS offers exceptional control precision. Its advanced control algorithms ensure accurate regulation of servo motor parameters, enabling high – precision positioning and smooth speed control. In applications such as semiconductor manufacturing or precision machining, where even the slightest deviation can lead to product defects, this servo drive’s precise control capabilities guarantee consistent and high – quality output. The ability to switch between different control modes provides flexibility to adapt to various production requirements.

Versatile Communication Capabilities

Equipped with support for multiple industrial communication protocols, the DKC10.3-018-3-MGP-01VRS can seamlessly integrate into complex automation systems. It enables real – time data exchange with Programmable Logic Controllers (PLCs), Human – Machine Interfaces (HMIs), and other automation devices. This allows for remote monitoring and control, facilitating efficient operation and maintenance of the production line. Whether in a large – scale factory or a specialized manufacturing facility, the servo drive’s communication versatility ensures smooth coordination of all components in the automation ecosystem.

Robust and Reliable Design

Built to withstand harsh industrial environments, the REXROTH DKC10.3-018-3-MGP-01VRS features a robust construction. Its wide operating temperature range and protection class ensure reliable operation even in challenging conditions. The high – power density design not only maximizes energy efficiency but also reduces the physical footprint of the drive, making it easier to install in control cabinets. Additionally, the built – in diagnostic functions continuously monitor the drive’s status, detecting potential issues early and minimizing production downtime.

User – Friendly Configuration

The DKC10.3-018-3-MGP-01VRS comes with intuitive configuration software, making it easy for engineers to set up and adjust parameters. The user – friendly interface simplifies the process of configuring motor settings, communication protocols, and control modes. This reduces the learning curve and enables quick deployment and integration into existing automation systems, saving time and effort during installation and maintenance.

REXROTH DKC10.3-018-3-MGP-01VRS

Application Field

The REXROTH DKC10.3-018-3-MGP-01VRS servo drive is widely applicable across multiple industries. In the automotive manufacturing industry, it is used to control servo motors in robotic assembly lines, ensuring precise positioning of components during vehicle production. From body welding to engine assembly, this servo drive’s high – precision control improves production efficiency and product quality.

In the electronics manufacturing sector, the DKC10.3-018-3-MGP-01VRS plays a vital role in the production of semiconductors and electronic devices. It controls the servo motors in pick – and – place machines, enabling accurate placement of tiny components on printed circuit boards. The servo drive’s ability to handle high – speed and precise movements is essential for meeting the strict requirements of the electronics industry.

It is also suitable for the packaging industry, where it controls the servo motors in packaging machines. Whether it’s filling, sealing, or labeling, the REXROTH DKC10.3-018-3-MGP-01VRS ensures smooth and accurate operation, increasing production speed and reducing waste. Additionally, in industries such as textiles, printing, and machine tools, this servo drive’s reliable performance and precise control contribute to enhanced productivity and quality.

Related Products

- REXROTH DKC10.3-030-3-MGP-01VRS: Similar to the 3-018-3-MGP-01VRS, but with a higher output current rating of 30 A. It is suitable for applications that require more power, such as driving larger servo motors in heavy – duty machinery or high – load production processes.

- REXROTH DKC11.3-018-3-MGP-01VRS: Belongs to a different series within REXROTH’s servo drive products. It may offer enhanced features or different performance characteristics, such as improved communication capabilities or more advanced control algorithms, making it suitable for more complex automation applications.

- REXROTH DKC10.3-018-7-MGP-01VRS: This model has a different power supply configuration compared to the 3-018-3-MGP-01VRS. It may be designed to operate with a different voltage range or power source, providing more flexibility for specific industrial setups with unique power requirements.

- REXROTH DKC01.3-018-3-MGP-01VRS: A smaller – scale servo drive with a lower power capacity. It is suitable for applications where less power is needed, such as in small – scale manufacturing equipment or testing setups. It may also have a different form factor and interface configuration compared to the 3-018-3-MGP-01VRS.

- REXROTH DKC10.3-018-3-MGP-02VRS: This variant may have different communication or control options. For example, it could support additional communication protocols or have a modified control interface, making it more suitable for specific industrial automation scenarios that require customized communication or control functionality.

Installation and Maintenance

Pre – installation preparation: Before installing the REXROTH DKC10.3-018-3-MGP-01VRS servo drive, ensure that the control cabinet is properly grounded and clean. Check the input voltage of the installation site to confirm it matches the requirements of the drive. Verify the compatibility of communication cables and encoder connections with the existing automation system. Prepare all necessary tools and hardware for mounting the drive securely in the control cabinet. Also, install the appropriate configuration software on the connected computer and ensure it is up – to – date for smooth setup and parameter adjustment.

Maintenance recommendations: Regularly inspect the DKC10.3-018-3-MGP-01VRS for any signs of overheating, abnormal noise, or visual damage. Clean the ventilation openings of the drive regularly to ensure proper heat dissipation. Periodically update the drive’s firmware to benefit from the latest features, bug fixes, and security enhancements. Monitor the communication status between the drive and other devices in the system to detect and resolve any potential communication issues promptly. If any problems are identified, refer to the product manual for troubleshooting steps or contact REXROTH’s technical support for professional assistance. Keep a record of the drive’s operating parameters and performance data for analysis and preventive maintenance purposes.

Product Guarantee

REXROTH is committed to the quality of the DKC10.3-018-3-MGP-01VRS servo drive. The product undergoes strict quality control and testing during the manufacturing process to meet the highest industry standards. REXROTH offers a comprehensive product guarantee, typically including a one – year warranty. During this period, if any quality issues arise due to manufacturing defects, REXROTH will provide free repair or replacement services. Additionally, REXROTH’s professional technical support team is available around the clock to assist customers with installation, configuration, and any operational questions. Whether it’s resolving technical problems, optimizing performance, or providing guidance on system integration, the support team ensures that customers can use the DKC10.3-018-3-MGP-01VRS with confidence, maximizing the value and reliability of their industrial automation systems.