Description

Product Overview

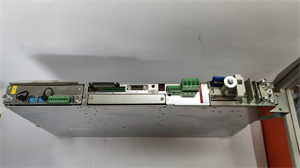

The REXROTH VT-HNC100-1-23/W-08-0-0 is likely a high – end control unit within Bosch Rexroth’s industrial automation product lineup, specializing in advanced motion control and system management. Leveraging Rexroth’s extensive expertise in industrial technology, this product is designed to meet the complex and precise requirements of modern manufacturing and automation processes. It may serve as the central control “brain” for various industrial systems, enabling seamless coordination and control of multiple components to ensure efficient, accurate, and reliable operation.

Whether integrated into large – scale factory automation networks or highly specialized production lines, the REXROTH VT-HNC100-1-23/W-08-0-0 plays a crucial role in enhancing overall productivity, improving product quality, and optimizing resource utilization. Its design emphasizes high – performance computing capabilities, broad compatibility with other Rexroth and third – party devices, ease of programming and operation, and adaptability to diverse industrial environments, making it an indispensable asset for industries aiming to achieve advanced automation.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | VT-HNC100-1-23/W-08-0-0 |

| Manufacturer | Bosch Rexroth |

| Product Type | [Likely a High – Performance Motion Control Unit or CNC Controller] |

| Input Voltage Range | [Estimated: 24 VDC (for internal electronics), 200 – 240 VAC (for power supply), based on common Rexroth control products] |

| Processor Type | [Potential: High – speed multi – core processor for fast data processing and control] |

| Memory Capacity | [Estimated: [X] GB of RAM for program storage and operation, [X] GB of flash memory for data logging and program backup] |

| Communication Protocols | Profibus, CANopen, Ethernet (including Ethernet/IP, Profinet), ensuring seamless integration with various industrial devices and networks |

| Number of Axes Controlled | [Estimated: Up to 8 axes, allowing for complex multi – axis motion control applications] |

| Control Modes | Position control, velocity control, torque control, enabling precise regulation of motion parameters |

| Operating Temperature Range | -10°C – 55°C |

| Protection Class | IP20 (suitable for indoor industrial environments), protecting against dust and limited contact |

| Dimensions | [Estimated: 300mm × 200mm × 100mm, size may vary depending on actual design] |

| Weight | [Estimated: 5 – 8 kg] |

| Response Time | [Estimated: ≤1 ms for rapid control response to ensure smooth motion] |

| Programming Languages Supported | [Possible: PLC programming languages (such as Ladder Diagram, Structured Text), as well as Rexroth – specific motion control programming languages] |

REXROTH VT-HNC100-1-23/W-08-0-0

Main Features and Advantages

Advanced Motion Control Capabilities

The REXROTH VT-HNC100-1-23/W-08-0-0 is expected to offer highly advanced motion control features. With its ability to control multiple axes simultaneously, it can execute complex motion profiles with high precision. In applications such as CNC machining centers, it can precisely control the movement of the spindle and linear axes, enabling the production of intricate parts with tight tolerances. Its advanced control algorithms ensure smooth acceleration and deceleration, reducing vibrations and improving the surface finish of machined components. The support for different control modes allows for flexible adaptation to various manufacturing processes, from high – speed cutting to delicate assembly operations.

High – Speed Data Processing and Communication

Equipped with a powerful processor and high – speed communication interfaces, the REXROTH VT-HNC100-1-23/W-08-0-0 can handle large amounts of data in real – time. It can quickly process sensor feedback, adjust control parameters, and communicate with other devices in the automation system. The support for multiple industrial communication protocols ensures seamless integration with PLCs, servo drives, sensors, and other automation components. This high – speed data processing and communication capability enables synchronized operation of multiple devices, improving the overall efficiency and responsiveness of the automation system. For example, in a robotic assembly line, it can coordinate the movement of multiple robotic arms in real – time, ensuring accurate and efficient component assembly.

User – Friendly Programming and Configuration

The REXROTH VT-HNC100-1-23/W-08-0-0 likely features a user – friendly programming and configuration interface. It supports common programming languages, making it accessible to a wide range of engineers and technicians. The intuitive software tools provided by Rexroth allow users to easily program motion sequences, set control parameters, and monitor system performance. Additionally, it may offer graphical programming interfaces, which simplify the development of complex motion control applications. This user – friendliness reduces the programming time and effort required, enabling faster deployment of automation systems and easier maintenance and modification in the future.

Robust and Reliable Design

Built with high – quality components and Rexroth’s robust engineering, the REXROTH VT-HNC100-1-23/W-08-0-0 is designed to operate reliably in harsh industrial environments. Its protection class safeguards it from dust, moisture, and minor impacts, ensuring stable operation over long periods. The unit is likely to have built – in diagnostic functions that can detect and report faults in real – time, enabling quick troubleshooting and minimizing downtime. The redundant design of critical components may also be incorporated to enhance reliability, ensuring continuous operation even in the event of a component failure.

REXROTH VT-HNC100-1-23/W-08-0-0

Application Field

The REXROTH VT-HNC100-1-23/W-08-0-0 can be applied in a wide variety of industries. In the automotive manufacturing industry, it can be used to control the movement of robotic arms in assembly lines, ensuring accurate and efficient installation of components such as engines, transmissions, and body panels. In the aerospace industry, it plays a vital role in CNC machining of high – precision aerospace components, where strict accuracy and quality requirements are essential.

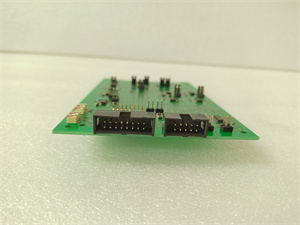

In the electronics manufacturing sector, it can manage the precise movement of pick – and – place machines, enabling the accurate placement of tiny electronic components on circuit boards. Additionally, it is suitable for use in the woodworking, metalworking, and plastic processing industries, where it can control the operation of CNC routers, lathes, and injection molding machines, respectively, to produce high – quality products with consistent precision.

Related Products

- REXROTH VT-HNC80-1-20/W-06-0-0: A potentially lower – performance variant with fewer controlled axes and less memory capacity, suitable for smaller – scale or less complex automation applications, such as small – batch production lines or simple robotic cells.

- REXROTH VT-HNC120-1-25/W-10-0-0: A higher – end model with enhanced processing power, more axis control capabilities, and larger memory, designed for extremely complex multi – axis motion control applications, like large – scale 5 – axis CNC machining centers or advanced robotic systems.

- REXROTH VT-HNC100-1-23/W-08-0-0 – A: A variant with a modified communication interface or additional software features, perhaps optimized for integration with specific types of industrial networks or for particular industry – specific applications, such as the food and beverage industry with its unique communication and control requirements.

- REXROTH VT-HNC100-1-23/W-08-0-0 – B: This version might have a different physical form factor or mounting options, making it more adaptable to different machine designs or installation environments, such as compact machinery with limited space.

- REXROTH VT-HNC100-1-23/W-08-0-0 – S: A specialized model, possibly designed for high – speed or high – precision applications that require ultra – fast response times and extreme accuracy, such as high – speed laser cutting or micro – machining operations.

Installation and Maintenance

Pre – installation preparation: Before installing the REXROTH VT-HNC100-1-23/W-08-0-0, carefully review the product manual to understand the specific installation requirements. Ensure that the installation environment meets the specified conditions, including temperature, humidity, and electrical supply stability. Verify the compatibility of the control unit with existing automation components, such as servo drives, motors, and sensors. Prepare all necessary tools and mounting hardware, and make sure the mounting surface is clean, flat, and properly grounded. Connect the power cables, communication cables, and signal cables according to the provided wiring diagrams, ensuring all connections are secure and correctly wired.

Maintenance recommendations: Regularly inspect the REXROTH VT-HNC100-1-23/W-08-0-0 for any signs of abnormal operation, such as unusual noises, overheating, or error messages on the display. Check the tightness of all cable connections and the integrity of the communication interfaces. Periodically update the control unit’s firmware to benefit from the latest features, performance improvements, and security patches. Use the built – in diagnostic tools to monitor the health of the unit and detect any potential issues early. In case of a malfunction, refer to the product manual for troubleshooting steps or contact Rexroth’s technical support team for assistance. Keep detailed records of all maintenance activities, including inspection dates, firmware updates, and any component replacements, for future reference and to ensure proper preventive maintenance.

Product Guarantee

Bosch Rexroth stands firmly behind the quality of the REXROTH VT-HNC100-1-23/W-08-0-0. The product undergoes rigorous quality control procedures during manufacturing to meet the highest industry standards. Bosch Rexroth typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, Bosch Rexroth will provide free repair or replacement services. Additionally, Rexroth’s professional technical support team is available 24/7 to assist customers with installation, operation, programming, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the REXROTH VT-HNC100-1-23/W-08-0-0 with confidence, maximizing the value and reliability of their industrial automation systems.