Description

Product Overview

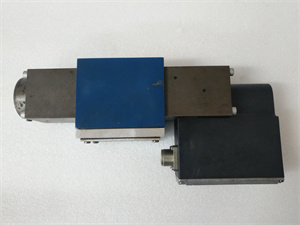

The Bosch Rexroth VT-HNC100-1-23/W-08-P-0 is a high – end digital axis controller within Bosch Rexroth’s VT – HNC100 series. Renowned for its precision and reliability in industrial automation, Bosch Rexroth has designed the VT – HNC100 – 1 – 23/W – 08 – P – 0 to offer comprehensive control capabilities. It serves as a crucial component in various automation systems, capable of managing both hydraulic and electric drives with great accuracy. This controller is designed to meet the complex demands of modern industrial applications, providing precise control over motor speed, position, and torque. It can be integrated into a wide range of industrial machinery, enhancing their performance and efficiency. Whether in large – scale manufacturing plants or specialized production lines, the Bosch Rexroth VT – HNC100 – 1 – 23/W – 08 – P – 0 plays a vital role in optimizing production processes and ensuring high – quality output.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | VT – HNC100 – 1 – 23/W – 08 – P – 0 |

| Manufacturer | Bosch Rexroth |

| Product Type | Digital Axis Controller |

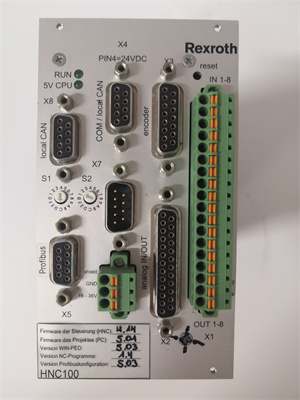

| Processor | 16/32 – bit MC68376 |

| Operating Voltage | 18 – 36VDC |

| Power Consumption | 8W |

| Memory | 1MB flash eeprom, 8KB eeprom, 256KB ram |

| Analog Inputs | 4 current inputs (4 – 20mA), 4 voltage inputs (±10V, differential type) |

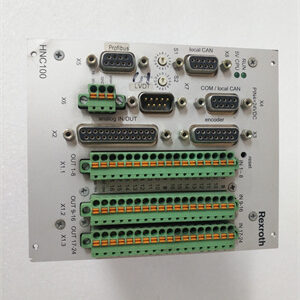

| Communication Bus | PROFIBUS DP |

| Digital I/O | 8 digital inputs/outputs (configurable to 8, 16, or 24) |

| Measuring System Support | Incremental or absolute (SSI) |

| Mounting | Wall – mounted housing |

| Dimensions | 263×58×28mm |

| Weight | Approximately 4.3kg |

REXROTH VT-HNC100-1-23/W-08-P-0

Main Features and Advantages

Precise Control: The Bosch Rexroth VT – HNC100 – 1 – 23/W – 08 – P – 0 offers extremely precise control over motor speed, position, and torque. This level of precision is crucial for applications that require high – accuracy movement, such as in precision machining or automated assembly lines. The advanced control algorithms ensure smooth and consistent operation, reducing errors and improving product quality.

Rich Communication Options: With support for communication protocols like PROFIBUS DP, it can be easily integrated into existing industrial automation systems. This allows for seamless data exchange with other components, such as PLCs, sensors, and actuators. It enables real – time monitoring and control, enhancing the overall efficiency of the automation system.

Flexible I/O Configuration: The digital I/O of the VT – HNC100 – 1 – 23/W – 08 – P – 0 is highly flexible, configurable to 8, 16, or 24 inputs and outputs. This adaptability makes it suitable for a wide range of applications, whether simple or complex, allowing users to customize the controller according to their specific requirements.

Reliable Operation: Built with high – quality components and Bosch Rexroth’s renowned engineering expertise, this controller is designed to operate reliably in harsh industrial environments. It has a wide operating temperature range and is protected against common industrial contaminants, ensuring stable performance over long periods.

Application Field

In industrial automation, the Bosch Rexroth VT – HNC100 – 1 – 23/W – 08 – P – 0 is extensively used. For example, in automotive manufacturing, it can control the movement of robotic arms in assembly lines, ensuring accurate and efficient installation of components. In the electronics manufacturing industry, it is used to manage the precise movement of pick – and – place machines, enabling the accurate placement of tiny electronic components on circuit boards.

In the field of medical equipment, it can be used to control the movement of various mechanical parts in diagnostic and treatment devices, ensuring precise and smooth operation. In the packaging industry, it helps in controlling the speed and position of conveyor belts and packaging machinery, optimizing the packaging process. Additionally, it is also suitable for use in the food and beverage industry, where it can control the movement of filling and capping machines, ensuring accurate and hygienic production.

REXROTH VT-HNC100-1-23/W-08-P-0

Related Products

- VT – HNC80 – 1 – 20/W – 06 – 0 – 0: A lower – performance variant with fewer capabilities, such as less memory and fewer axis control options. It is suitable for less complex applications where cost – effectiveness is a priority.

- VT – HNC120 – 1 – 25/W – 10 – 0 – 0: An upgraded model with enhanced processing power, more axis control, and larger memory. It is designed for highly complex industrial applications that demand high – speed and high – precision control.

- VT – HNC100 – 1 – 23/W – 08 – P – 0 – A: A variant with modified software features, perhaps optimized for specific industries like the food and beverage industry, with additional functions related to hygiene control or specific process requirements.

- VT – HNC100 – 1 – 23/W – 08 – P – 0 – B: This version has a different physical form factor, making it more adaptable to different machine designs or installation environments, such as compact machinery with limited space.

- VT – HNC100 – 1 – 23/W – 08 – P – 0 – S: A specialized model for high – speed and high – precision applications, with features like faster response times and higher accuracy, suitable for industries like aerospace or semiconductor manufacturing.

Installation and Maintenance

Pre – installation preparation: Before installing the Bosch Rexroth VT – HNC100 – 1 – 23/W – 08 – P – 0, carefully read the product manual. Ensure that the installation environment meets the specified temperature, humidity, and electrical requirements. Verify the compatibility of the controller with other components in the system. Prepare all the necessary tools and mounting hardware, and make sure the mounting surface is clean, flat, and properly grounded. Connect the power, communication, and signal cables according to the wiring diagrams provided.

Maintenance recommendations: Regularly inspect the VT – HNC100 – 1 – 23/W – 08 – P – 0 for any signs of abnormal operation, such as unusual noises, overheating, or error messages. Check the tightness of all cable connections and the integrity of the communication interfaces. Periodically update the controller’s firmware to benefit from the latest features, performance improvements, and security patches. Use the built – in diagnostic tools to monitor the health of the unit and detect any potential issues early. In case of a malfunction, refer to the product manual for troubleshooting steps or contact Bosch Rexroth’s technical support team.

Product Guarantee

Bosch Rexroth stands firmly behind the quality of the Bosch Rexroth VT – HNC100 – 1 – 23/W – 08 – P – 0. The product undergoes rigorous quality control procedures during manufacturing to meet the highest industry standards. Bosch Rexroth typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, Bosch Rexroth will provide free repair or replacement services. Additionally, Bosch Rexroth’s professional technical support team is available to assist customers with installation, operation, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the Bosch Rexroth VT – HNC100 – 1 – 23/W – 08 – P – 0 with confidence, maximizing the value and reliability of their industrial automation systems.