Description

Product Overview

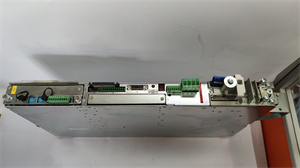

The Rexroth TVD1.3-15-03 is likely a specialized control or drive – related component within Bosch Rexroth’s diverse portfolio of industrial automation solutions. Leveraging Rexroth’s extensive expertise in engineering high – quality industrial products, the TVD1.3-15-03 is presumably designed to deliver reliable performance and precise control in various industrial applications. It may serve as a crucial element in systems that require accurate regulation of motion, power, or other critical parameters, contributing to the seamless operation of industrial machinery and production lines.

As part of Rexroth’s commitment to innovation, the TVD1.3-15-03 is likely engineered to meet the evolving demands of modern industries. It could be used to control the speed and torque of motors in manufacturing equipment, manage the flow of hydraulic fluids in heavy – duty machinery, or perform other essential functions in automation setups. Whether integrated into large – scale factory automation systems or smaller, specialized production facilities, the Rexroth TVD1.3-15-03 plays a significant role in enhancing productivity, improving product quality, and ensuring the overall efficiency of industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | TVD1.3-15-03 |

| Manufacturer | Bosch Rexroth |

| Product Type | [Likely a Control Module or Drive Unit] |

| Input Voltage Range | [Estimated: 200 – 480 VAC, typical for many industrial drive – related products] |

| Output Power Rating | 1.3 kW |

| Control Modes | [Possible: Speed control, Torque control, Position control] |

| Communication Protocols | [Possible: Profibus, CANopen, Ethernet/IP] |

| Operating Temperature Range | -10°C – 55°C |

| Protection Class | [Estimated: IP20 for indoor use] |

| Dimensions | [Estimated: 150mm × 100mm × 80mm] |

| Weight | [Estimated: 2 – 4 kg] |

| Response Time | [Estimated: ≤10 ms for quick – reacting control functions] |

| Signal Input Types | [Possible: Analog voltage, Digital signals] |

REXRTOH TVD1.3-15-03

Main Features and Advantages

Precise Control Performance

The Rexroth TVD1.3-15-03 likely offers precise control capabilities, enabling accurate regulation of various parameters. If it is a drive unit, it can precisely control the speed and torque of motors, ensuring smooth and consistent operation of machinery. This precision is crucial in applications such as CNC machining, where even minor variations in motor performance can affect the quality of the final product. With advanced control algorithms, the TVD1.3-15-03 can quickly respond to changes in input signals, maintaining stable operation and reducing errors.

Flexible Communication Options

Equipped with support for multiple communication protocols, the TVD1.3-15-03 can be easily integrated into existing industrial automation systems. It can communicate seamlessly with programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other devices, enabling real – time monitoring and control. This flexibility allows for greater adaptability in different industrial environments, facilitating the integration of the component into complex automation networks. Whether in a large – scale manufacturing plant or a smaller production facility, the Rexroth TVD1.3-15-03 can be configured to work harmoniously with other equipment, enhancing the overall efficiency of the system.

Robust and Reliable Design

Built with high – quality components and Rexroth’s proven engineering, the Rexroth TVD1.3-15-03 features a robust and reliable design. It is designed to withstand the harsh conditions commonly found in industrial environments, including temperature fluctuations, vibrations, and electrical interference. The protection class of IP20 ensures that the component is protected against dust and limited contact, safeguarding its internal components and ensuring long – term reliability. This durability reduces the need for frequent maintenance and replacement, minimizing downtime and increasing the productivity of industrial operations.

User – Friendly Operation

The TVD1.3-15-03 is likely designed with user – friendliness in mind. It may feature an intuitive interface that allows operators to easily configure and monitor its operation. The component might have built – in diagnostic functions that can quickly identify and report any faults or issues, facilitating troubleshooting and reducing the time required for maintenance. Additionally, its simple installation process and clear instructions make it accessible to a wide range of users, even those with limited technical expertise. This user – friendly design helps to improve operational efficiency and reduce the learning curve for new users.

REXRTOH TVD1.3-15-03

Application Field

The Rexroth TVD1.3-15-03 can be applied in a wide range of industries. In the automotive manufacturing industry, it could be used to control the motors in robotic arms on assembly lines, ensuring accurate and efficient installation of components. Its precise control capabilities are essential for maintaining the high – quality standards required in automotive production.

In the packaging industry, the TVD1.3-15-03 can be used to drive conveyor belts and control the movement of packaging machinery. Its reliable performance and precise control help to ensure the smooth operation of the packaging process, increasing productivity and reducing the risk of product damage.

In the metalworking industry, it can be used to control the speed and torque of motors in machining centers, enabling precise cutting and shaping of metal parts. The component’s ability to provide stable and accurate control is crucial for achieving high – quality results in metalworking applications.

Related Products

- Rexroth TVD1.0-10-02: A lower – power variant with a 1.0 kW output rating, suitable for applications that require less power, such as small – scale manufacturing equipment or light – duty conveyor systems.

- Rexroth TVD1.5-20-04: A higher – power model with a 1.5 kW output, designed for more demanding applications, like heavy – duty machinery or large – scale production lines that require greater power and control.

- Rexroth TVD1.3-15-03 – A: A variant with modified communication interfaces or additional software features, perhaps optimized for specific industries or applications that require enhanced connectivity or customized control functions.

- Rexroth TVD1.3-15-03 – B: This version might have a different physical form factor or mounting options, making it more suitable for installation in compact machinery or in environments with limited space.

- Rexroth TVD1.3-15-03 – S: A specialized model, possibly designed for high – speed or high – precision applications, with features like faster response times or higher accuracy to meet the stringent demands of industries such as aerospace or semiconductor manufacturing.

Installation and Maintenance

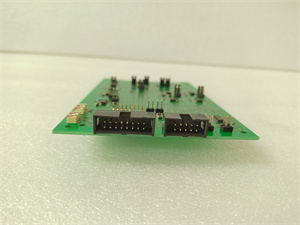

Pre – installation preparation: Before installing the Rexroth TVD1.3-15-03, carefully review the product manual to understand the specific installation requirements. Ensure that the installation environment meets the specified temperature, humidity, and electrical supply conditions. Verify the compatibility of the component with existing equipment and systems, including motors, sensors, and control units. Prepare all necessary tools and mounting hardware, and make sure the mounting surface is clean, flat, and properly grounded. Connect the power cables, communication cables, and signal cables according to the provided wiring diagrams, ensuring all connections are secure and correctly configured.

Maintenance recommendations: Regularly inspect the Rexroth TVD1.3-15-03 for any signs of abnormal operation, such as unusual noises, overheating, or error messages. Check the tightness of all cable connections and the integrity of the communication interfaces. Periodically clean the component’s exterior to remove dust and debris, especially if it is installed in a dirty environment. If the component has adjustable parameters, monitor and adjust them as needed to maintain optimal performance. In case of any malfunction, refer to the product manual for troubleshooting steps. If the problem persists, contact Rexroth’s technical support team for professional assistance. Keep detailed records of all maintenance activities, including inspection dates, component replacements, and any issues resolved, for future reference.

Product Guarantee

Bosch Rexroth stands firmly behind the quality of the Rexroth TVD1.3-15-03. The product undergoes strict quality control procedures during manufacturing to meet the highest industry standards. Bosch Rexroth typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, Bosch Rexroth will provide free repair or replacement services. Additionally, Rexroth’s professional technical support team is available 24/7 to assist customers with installation, operation, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the TVD1.3-15-03 with confidence, maximizing the value and reliability of their industrial automation systems.