Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | Rockwell SST-PB3-CLX-RLL |

| Manufacturer | Rockwell Automation |

| Product category | Industrial Communication Module |

| Description | PROFIBUS DP Master/Slave module for Rockwell ControlLogix systems |

| Operating Voltage | 24V DC (±10%) |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Protection Rating | IP20 |

| Dimensions (L x W x H) | 145 mm x 36 mm x 131 mm |

| Weight | 0.395 kg |

| Communication | PROFIBUS DP (RS-485) |

| Data Transfer Rate | 9.6 Kbps to 12 Mbps |

| Interfaces | 1 x PROFIBUS port (DB9 female), 1 x Ethernet port (RJ45) |

| Certifications | CE, UL, RoHS compliant |

| Compatibility | Compatible with Rockwell ControlLogix 5000 systems |

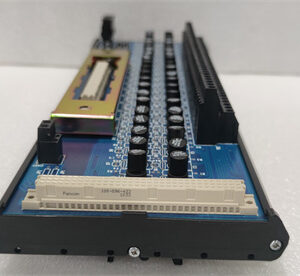

Rockwell SST-PB3-CLX-RLL

Product Introduction

The Rockwell SST-PB3-CLX-RLL is a high-performance PROFIBUS DP Master/Slave module designed for Rockwell ControlLogix systems. It facilitates seamless communication between ControlLogix processors and PROFIBUS DP remote I/O devices, ensuring efficient data exchange and control in industrial automation environments.

Core Advantages and Technical Highlights

High Precision and Reliability:

-

Ensures accurate and reliable communication between ControlLogix systems and PROFIBUS DP devices.

Easy Integration:

-

Fully integrates into Rockwell Automation environments, supporting remote configuration and monitoring via Rockwell RSLinx.

Dynamic Configuration:

-

Allows dynamic addition and removal of PROFIBUS slave devices while the system is in operation.

Robust Design:

-

Built to withstand harsh industrial environments, ensuring long-term reliability.

User-Friendly Configuration:

-

Utilizes Rockwell RSLogix5000’s Add-On-Profile for easy setup and configuration without the need for ladder logic.

Wide Application Range:

-

Suitable for various industrial sectors, including automotive, material handling, water and wastewater treatment, food and agriculture, oil and gas, pharmaceutical, and mining.

Rockwell SST-PB3-CLX-RLL

Typical Application Scenarios

The Rockwell SST-PB3-CLX-RLL is widely used in various industrial sectors:

-

Automotive Manufacturing: For real-time control and monitoring of production lines.

-

Water and Wastewater Treatment: For controlling pumps and valves in treatment processes.

-

Food and Beverage: For precise control in food processing and packaging.

-

Pharmaceutical Industry: For accurate control in pharmaceutical production.

Related Model Recommendations

-

Rockwell ControlLogix 5000 Series: The primary system that the SST-PB3-CLX-RLL is designed to support.

-

Rockwell RSLinx: Software for remote configuration and monitoring of the module.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

-

Ensure the environment meets the specified temperature and humidity requirements (0°C to +60°C, 5% to 95% RH non-condensing). Use shielded cables and proper grounding to minimize electromagnetic interference.

Maintenance Suggestions:

-

Regularly inspect connections for wear and clean the module with a static-free cloth to ensure optimal heat dissipation. Perform annual full calibration and quarterly leak checks (He mass spec recommended). Replace O-rings every 2 years and verify ground connections (impedance <1Ω).

Service and Guarantee Commitment

Rockwell Automation stands behind the quality and reliability of the SST-PB3-CLX-RLL, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Their dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations.