Description

Product Overview

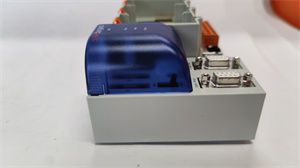

The SAIA PCD3.M5540 is a high – end programmable controller that represents the pinnacle of SAIA’s technological innovation within the PCD3 series. Engineered to address the most demanding industrial automation requirements, this controller is a reliable and powerful solution for complex manufacturing, energy management, and building automation systems. SAIA, a leading name in the industrial automation domain, has meticulously designed the PCD3.M5540 to deliver exceptional performance, precision control, and seamless integration capabilities.

At the heart of the SAIA PCD3.M5540 lies a state – of – the – art processing unit, enabling it to handle intricate control algorithms and process vast amounts of data in real – time. It serves as the nerve center of industrial operations, coordinating multiple processes simultaneously with pinpoint accuracy. Whether it’s managing high – speed production lines in automotive manufacturing, optimizing energy – intensive processes in power plants, or integrating diverse building systems for intelligent control, the PCD3.M5540 ensures smooth, efficient, and reliable operation. Its advanced features and flexibility make it an indispensable asset for industries seeking to enhance productivity, reduce downtime, and achieve operational excellence.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | PCD3.M5540 |

| Manufacturer | SAIA |

| Product Type | High – Performance Programmable Controller |

| Processor | 64 – bit multi – core microprocessor |

| Memory | 4 GB program memory, 2 GB data memory, expandable via SD card |

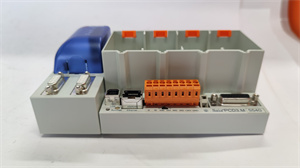

| Digital Inputs | 64 channels, 24 VDC with high – noise immunity |

| Digital Outputs | 64 channels, 3 A per channel, capable of driving high – load devices |

| Analog Inputs | 16 channels, 0 – 10 V, 4 – 20 mA, ±10 V, 16 – bit high – precision resolution |

| Analog Outputs | 8 channels, 0 – 10 V, 4 – 20 mA, with high – accuracy output stability |

| Communication Protocols | Modbus RTU, Profibus, Ethernet/IP, CANopen, OPC UA, MQTT, 5G – enabled communication |

| Power Supply | 100 – 240 VAC, 50/60 Hz or 24 VDC ±20% |

| Operating Temperature | -25°C to 70°C |

| Protection Class | IP20 for indoor use, optional IP67 enclosure for harsh environments |

| Dimensions | 150mm x 120mm x 80mm |

| Weight | 1.2 kg |

| Real – Time Clock | Built – in, for accurate timestamping of events |

| Diagnostic Features | Comprehensive self – diagnosis, with LED indicators for status monitoring |

SAIA PCD3.M5540

Main Features and Advantages

Unrivaled Processing Power

The SAIA PCD3.M5540 is powered by a 64 – bit multi – core microprocessor, providing unparalleled processing speed and efficiency. This allows it to execute complex control programs instantaneously, even when handling a massive influx of data from numerous sensors and devices. In a large – scale manufacturing plant with hundreds of interconnected machines, the PCD3.M5540 can analyze data in real – time, make split – second decisions, and adjust processes accordingly, ensuring continuous and error – free production.

Extensive and Flexible I/O System

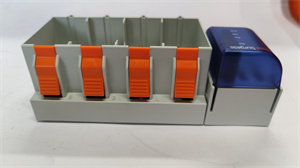

With 64 digital inputs, 64 digital outputs, 16 analog inputs, and 8 analog outputs, the PCD3.M5540 offers an extensive I/O configuration. The high – current – rated digital outputs can directly control heavy – duty actuators, while the high – precision analog I/O channels enable accurate measurement and control of critical process variables. Moreover, the expandable memory and multiple expansion slots allow users to customize the controller to meet specific application requirements, making it adaptable to a wide range of industrial scenarios.

Advanced Communication Capabilities

Supporting a comprehensive suite of communication protocols, including OPC UA, MQTT, and 5G – enabled communication, the SAIA PCD3.M5540 excels in connectivity. It can seamlessly integrate with enterprise – level management systems, cloud – based platforms, and other industrial devices, enabling real – time data sharing and remote monitoring from anywhere in the world. This facilitates efficient collaboration between different departments, improves decision – making processes, and enables proactive maintenance, reducing unplanned downtime.

Robust and Reliable Design

Built to withstand the harshest industrial environments, the PCD3.M5540 has a wide operating temperature range of -25°C to 70°C and offers an optional IP67 enclosure for protection against dust, water, and extreme conditions. Its high – quality components, strict manufacturing standards, and comprehensive self – diagnostic features ensure long – term reliability and minimal maintenance requirements. The built – in real – time clock and LED status indicators further enhance its usability, allowing for quick identification of issues and efficient troubleshooting.

SAIA PCD3.M5540

Application Field

In the automotive manufacturing industry, the SAIA PCD3.M5540 can be used to control the entire production line, from the stamping of body parts to the final assembly of vehicles. It can manage the operation of robotic arms, coordinate the movement of conveyor belts, and monitor the quality of each component in real – time, ensuring high – precision production and compliance with strict quality standards.

For power generation plants, whether traditional fossil – fuel – based or renewable energy facilities, the PCD3.M5540 plays a crucial role in optimizing operations. It can control the operation of turbines, generators, and other critical equipment, adjust energy production based on demand, and manage the integration of renewable energy sources into the grid, enhancing overall energy efficiency and reliability.

In intelligent building automation, the SAIA PCD3.M5540 can integrate and manage all aspects of a building’s systems, including HVAC, lighting, security, and elevator control. It can optimize energy consumption by adjusting HVAC settings based on occupancy patterns and weather forecasts, control lighting levels to create a comfortable and energy – efficient environment, and manage access to different areas of the building, providing a seamless and intelligent experience for occupants.

Related Products

- SAIA PCD3.M5530: A more basic version of the M5540, with fewer I/O points, lower memory capacity, and limited communication protocol support. It is suitable for smaller – scale industrial applications or projects with more modest requirements.

- SAIA PCD3.M5550: An upgraded model with enhanced features, such as more I/O expansion options, higher processing speed, and additional advanced communication interfaces. It is designed for extremely complex industrial applications that demand top – tier performance and functionality.

- SAIA PCD4.M5540: A next – generation model that may feature even more advanced processing capabilities, increased memory, and support for emerging industrial standards. It is targeted at industries with rapidly evolving automation needs.

- SAIA HMI 10E: A high – resolution human – machine interface specifically designed to work with the M5540. It provides an intuitive and user – friendly interface for operators to monitor and control industrial processes, enhancing productivity and ease of use.

- SAIA I/O Expansion Modules: These modules can be added to the M5540to further expand its I/O capacity. For example, additional digital I/O modules can be used to connect more sensors and actuators, while analog I/O expansion modules can increase the precision of process control.

Installation and Maintenance

Pre – installation preparation: Before installing the SAIA PCD3.M5540, carefully review the detailed installation manual. Ensure that the installation environment meets the specified temperature, humidity, and electrical requirements. Select an appropriate mounting location, such as a DIN – rail in a control cabinet or an industrial enclosure, ensuring proper ventilation and easy access for future maintenance. Prepare all necessary tools, including screwdrivers, wire strippers, and cable connectors. Connect the power supply cable to a stable power source, either 100 – 240 VAC or 24 VDC within the specified tolerance range. Then, connect the input and output cables to the relevant industrial devices according to the provided wiring diagrams, ensuring all connections are secure, properly insulated, and clearly labeled. Configure the communication settings based on the requirements of the industrial network, and verify the compatibility of the communication protocols with other connected devices.

Maintenance recommendations: Regularly inspect the SAIA PCD3.M5540 for any signs of abnormal operation, such as unusual noises, excessive heat, or error messages on the display. Check the tightness of all cable connections, including power, I/O, and communication cables, on a routine basis to ensure reliable operation. Clean the exterior of the controller and, if using an enclosure, the interior as well, to remove dust and debris, especially in dusty environments. Update the controller’s firmware regularly to benefit from the latest features, performance improvements, and security patches. Utilize the built – in self – diagnostic features to monitor the health of the device and identify any potential issues early. In case of a malfunction, refer to the detailed troubleshooting guide in the product manual or contact SAIA’s dedicated technical support team for professional assistance. Keep comprehensive records of all maintenance activities, including inspection dates, firmware updates, component replacements, and any issues resolved, for future reference and to ensure proper long – term maintenance of the device.

Product Guarantee

SAIA is fully committed to the quality and reliability of the SAIA PCD3.M5540. The product undergoes rigorous and comprehensive quality control procedures during manufacturing to meet and exceed the highest industry standards. SAIA offers an extended warranty period, providing customers with peace of mind against manufacturing defects. In the unlikely event of a defect within the warranty period, SAIA will promptly provide free repair or replacement services. Additionally, SAIA’s professional technical support team is available 24/7 to assist customers with any questions or issues related to installation, operation, and maintenance. Whether it’s helping with complex system integration, resolving technical glitches, or providing advice on optimizing the performance of the PCD3.M5540, SAIA is dedicated to ensuring that customers can rely on this product for their most critical industrial automation needs.